Sfaturi eficiente de top pentru procesul de șlefuire și sudare

25.08.2020Cum să faceți procesul de măcinare și sudare eficient și eficient?

În ciuda tuturor progreselor tehnologice și automatizării, procesul de măcinare și sudare este și va rămâne probabil o operație manuală intensivă. Când cauciucul intră în contact cu șoseaua, conceptul este măcinat. Sau, mai precis, este atunci când bobul vine în contact cu metalul.

Măcinarea poate părea a fi un proces simplu, cu toate acestea, pentru rezultate eficiente, este imperativ să fim atenți la detalii. Procesul necesită aplicarea unei presiuni corecte asupra îngerilor corecți. Procedând astfel, veți asigura îndepărtarea majorității metalelor într-un timp scurt.

Există mai multe variabile care sunt eficiente pentru fluxul lin al pieselor. Indiferent de cât de rapid și de procesul upstream actualizat pe care îl utilizați, ar dura câteva zile, dacă nu luni, pentru a trece prin departamentul de rectificare.

Acest subiect este extrem de extins; cu toate acestea, vă prezentăm câteva dintre cele mai eficiente sfaturi pentru a asigura succesul operațiilor dvs. de măcinare. Acești factori vă vor oferi câteva idei inițiale.

Cum să asigurați succesul procesului de măcinare și sudare

Instrument corect

Make sure that your power tools are not consumable like the grinding discs. Therefore, you need to be selective when it comes to grinders. Do go with any, in fact, choose that one that can adequately handle your job’s amperage.

For example, if the applications require 8 to 10 amps of pressure and you opt for 6 amps, right-angle grinder. We can assure you are that are in trouble from the very beginning. As the process would move forwards, things would get worse.

Since grinder is not a tool that you would throw away, therefore, we highly recommend investing in it. Instead of choosing any random grinder, go with a fine-quality industrial level grinder. It would cost you almost double, however, you can measure its operating life in years, and not in weeks.

Both the flap discs and the grinding discs are compatible with the right-angle grinders. Combining a low-quality grinder would high-quality grinding discs would yield better results. However, it would lack the smoothness of premium quality grinders and grinding discs.

Safety Comes First

When you use the right tool for the job, it automatically ensures safe operations. For instance, using a grinder without guarding would open doors to a lot of potential injuries. Also, if the OSHA figures this, the company would have to pay a hefty fine.

Yes, we understand that the guard can be troublesome in some situations. However, without the guards, things can get serious. Things would become even worse if you are using the wrong tool or you are underpowered.

So, if you are planning to grind in the tight areas, removing your guard and squeezing in the right-angle grinder is not the way to go about it. Use the file grinder. It would be the right tool to guarantee job efficiency and accuracy.

Before you change the abrasive media, it is important to unplug the tool. When changing the media, we recommend using the power tool’s head in order to lock the key button. Put the tool on your forearm, facing upwards. Now take your time and remove the abrasive.

Performing these steps would offer more control during abrasive changeout. In addition, it won’t allow the abrasive to drop. After all, dropped abrasive is among the commonly overlooked reason behind abrasive failure.

Also, the fall of the disc during a high-RPM right angle grinder can lead to some serious damage. You need to be extra careful as the smallest crack can make the discs lose during the operation. Too often the operators are putting back the disc after it drops out. Of course, they do inspect it first, but this is not a reliable and safe solution.

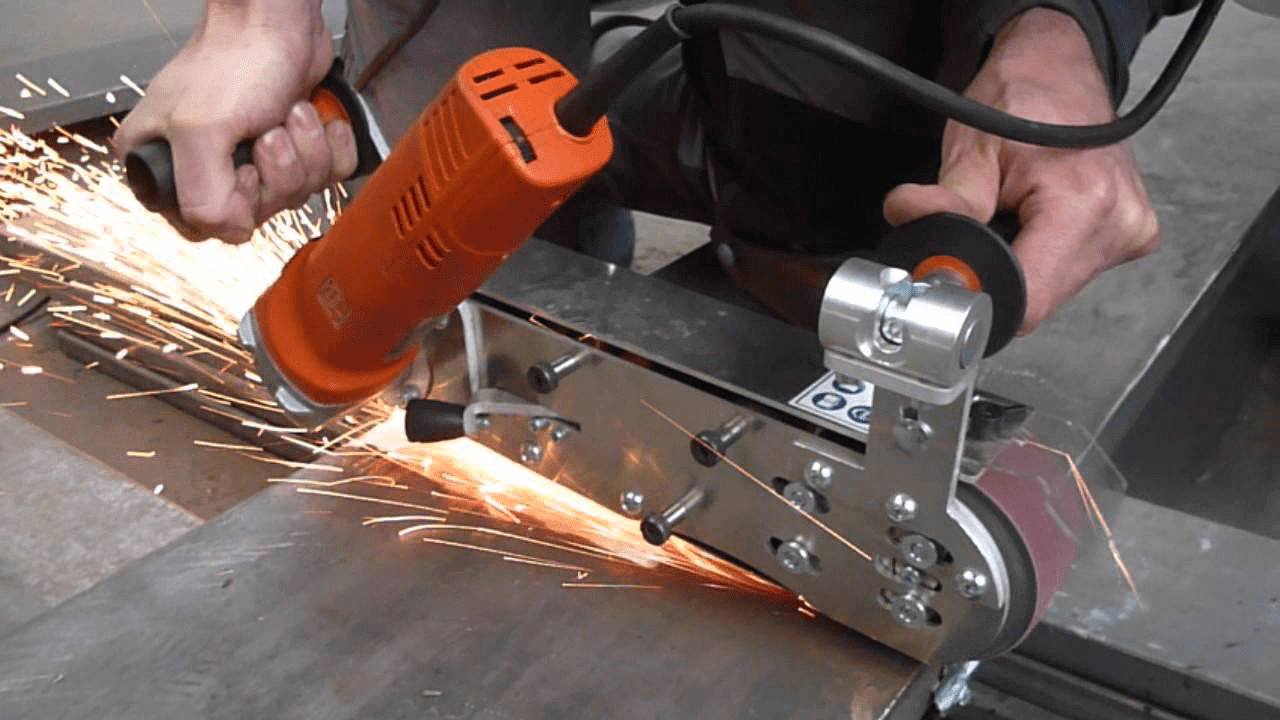

Spark Flow

Limited shops do have an ammeter at hand. It is a tool that you can use to keep a close check on the operator. It lets you determine whether the operator is pushing too hard or it is taking things lightly. It is possible to alter the change depending upon the grinding wheel and the tool.

Optimal pressure for the industrial grinding application ranges between eight to ten amps. In case, the ammeters show reading above this range, you need to slow down. However, if it shows below that range, you need to gear up.

Unfortunately, not all shops have ammeter at hand. Therefore, you need an alternative. The good news almost all applications produce sparks during the grind and welding process. Manufacturers use these sparks as an indication of the pressure. These sparks act as a visual ammeter.

Wondering how the sparks can help determine whether the process is working effectively or not? In most cases, the sparks would flow about three to four feet away from the work-place. If you find the sparks not following this particular pattern it means you are either overdoing it or underdoing it.

When you push too hard, it would overheat and overload the disc. This would result in the grains to glaze over. They would then become smooth. Since the grains are no longer cutting into the weld, therefore there would be spark reduction.

Likewise, when you are not pushing enough, you are not fully engaging in the workplace. Every disc rotation would not yield enough weld metal.

Pay heed to the Grinder Sound

The grinder’s sound is another effective way to figure out the problem. Applying the right pressure would produce a sound that has a contact pitch. In case, you are underdoing, the pitch volume would increase. In the case of overdosing, there would a drop in the volume.

The Right Working Angle of Grind and Welding Process

In general, you would have to use the grinding disc at angles that are five to ten degrees horizontal. Also, the pattern present on the disc face should be double its thickness. For example, if the pattern is 0.5” wide, the disc should be 0.25” thick.

If you have a disc thickness of 0.25”, but the wear pattern is let’s say 0.75” and your approach is flat. It means that you would the angle approach is not appropriate. It is too high, especially when several grinding disc’s grains will be engaging together.