Автомобильная промышленность

2020-03-21What is CNC Automotive?

The CNC automotive parts industry is the foundation and an important part of the development of the auto industry. The vehicle has about 30,000 parts. They can be divided into automotive engine system parts, body system parts, chassis system parts, electrical and electronic equipment, and general parts according to their functions. According to the material classification, it can be divided into metal parts and non-metal parts. Among them, metal parts account for about 60% -70%, and non-metal parts account for about 30% -40%.

Автомобильные пресс-формы с ЧПУ относятся к пресс-формам, используемым в автомобильной сфере. Их называют «матерями автомобильной промышленности». Более 90% деталей в автомобильном производстве используют формование пресс-форм.

Как правило, для автомобиля требуется от 1000 до 1500 комплектов штампов. На его долю приходится около 40% от общего объема выпуска автомобилей. Имеется около 800 комплектов форм для пластмассы, около 300 пар форм для листового металла и около 100 комплектов форм для литья под давлением. Автомобильные штамповочные штампы - важное техническое оборудование для автомобильного производства. На их разработку и производство приходилось около двух третей всего цикла разработки автомобиля. Они стали одним из главных препятствий. Автомобильные штамповочные штампы отличаются большими размерами, сложными рабочими поверхностями, высокими техническими стандартами и являются высокотехнологичным продуктом.

Автомобильные приложения с ЧПУ

Автоматическая 1 автомобильная штамповка в основном относится к деталям необходимой формы и размера. Эти заготовки получают путем деформации или отделения металлического материала от штамповочной головки, выдавливаемой под действием внешней силы. Широко используется в автомобильных чехлах, системах кузова, системах сидений, системах приборов и выхлопных системах. Металлические части корпуса - это почти все штампованные детали, а штампованные детали для автомобилей - это последующая отрасль производства автомобильных пресс-форм с ЧПУ.

Штамповка на кузове автомобиля условно делится на накладки, балочные панели и обычные штампованные панели. Печать, которая может четко отображать характеристики автомобиля, - это автомобильная панель. Следовательно, более конкретная автомобильная пресс-форма может быть названа «автомобильной пресс-формой для штамповки листов». Прямо как автомобильный слепок.

Large and medium-sized automobile cover molds are an important part of body manufacturing technology and a key link in forming the independent development capability of automobiles. Automotive mold products include automobile cover molds, tire molds, plastic inner and outer molds, automotive lighting molds, automotive bumper molds and instrument panel molds.

Automotive Mold Market Development

With the increase in the development of new passenger vehicle models, the number of new models introduced has increased year by year. With the growth of the automotive market and the intensification of competition in the automotive market, the capacity of the automotive mold market will grow rapidly in the future. This is also the result of the rapid development of the automotive industry and the rapid development of new models.

Luo Baihui, secretary-general of the International Model Association, said that the market demand for automotive panel molds mainly depends on the number of new models to be launched each year, and the number of new models to be delivered mainly depends on the development of new models. Passenger cars (including cars with less than 9 seats, MPV, SUV, and minibus, etc.).

Car Cover Mold Level

According to the category of cover parts and the requirements of car manufacturers, car cover molds can be divided into three levels: low-end, mid-end and high-end. Among them, the supply of molds with low technical content is oversupply, and the profit margin of the market is narrow. The competition in the middle-end mold market is becoming increasingly fierce, and high-end molds with high technological content are far from meeting the market demand, and the development space is huge.

In the production of CNC automotive molds, Essai Mold has formed its own automotive mold system.

1. Automatic 3D design

From a design perspective, the manufacturing of high-end automotive stamping molds requires a parametric design of the molds. We need to combine software template technology to actively and effectively conduct secondary development to form a series of fixed, standardized design parameters, design templates, and achieve complete correlation and drive of parameters. By changing the parameters of the mold parts, quickly change the CAE results, mold process, and optimize the structure of the mold.

2. Simulating Stamping Process-Computer Aided Engineering (CAE)

The manufacture of automotive molds is inseparable from effective plate forming simulation software, and high-end automotive molds require full-process finite element simulation technology. An effective plate forming simulation software can improve the success rate of high-end automotive mold development and greatly shorten the manufacturing cycle of high-end automotive mold development. It can simulate and analyze the formability of automotive stamping parts, determine the difficulty of forming, and the key areas prone to stamping quality defects.

On the other hand, it can also calculate the roughness of automotive stamping parts. Secondly, it can also be used for selective and targeted simulation analysis of the structure and process plan of automotive molds. In addition, it can also provide quantitative analysis and judgment for the debugging of automobile molds. Data, determine feasible debugging solutions and provide specific technical parameters for the solutions. In short, the finite element simulation of the entire process can iteratively optimize the structure and process plan of automotive molds. In addition, we can use various simulations. It can be used to quantitatively analyze and verify the feasibility and reliability of automotive mold design before the on-site mold debugging, to optimize and improve the mold design in time.

3. Digital mold technology

Технология цифровых автомобильных пресс-форм в основном включает следующие аспекты: 1. Дизайн для технологичности (DFM). Учитывайте и анализируйте технологичность в процессе проектирования, чтобы обеспечить успех процесса. 2, технология поддержки дизайна поверхности пресс-формы, разработка интеллектуальной технологии проектирования профиля. 3. CAE помогает анализировать и моделировать процесс штамповки, прогнозировать и решать возможные дефекты и проблемы формования. 4. Замените традиционный двухмерный дизайн трехмерным дизайном пресс-формы. 5. В процессе производства пресс-форм используются технологии CAPP, CAM и CAT. 6 Под руководством цифровых технологий решите проблемы в процессе обработки тестовых форм и штамповки.

4. Автоматизация обработки пресс-форм.

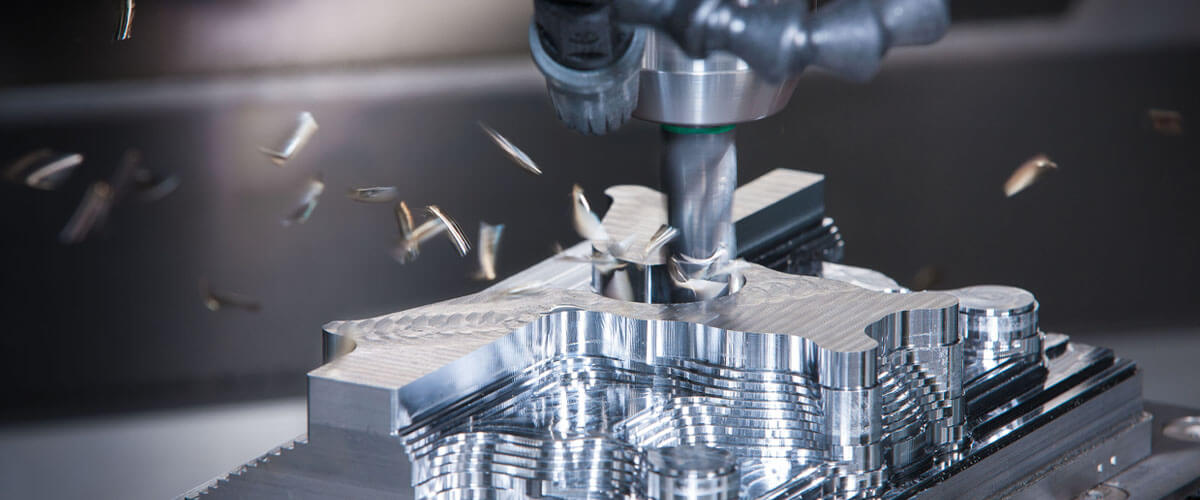

Оснащен станком с ЧПУ с двумя столами и устройством автоматической смены инструмента (АТС). Это как оптоэлектронные системы управления для автоматической обработки, так и онлайн-системы измерения деталей. Обработка с ЧПУ эволюционировала от простой контурной обработки до полной обработки контуров и структурных поверхностей, от среднескоростной обработки до низкоскоростной обработки и высокоскоростной обработки.

5. Материал пресс-формы и технология обработки поверхности.

Качество и характеристики материалов для форм являются важными факторами, влияющими на качество, срок службы и стоимость форм. Ковкий чугун обладает хорошей ударной вязкостью и износостойкостью, хорошими сварочными характеристиками, обрабатываемостью и характеристиками поверхностного упрочнения. Причем стоимость ниже легированного чугуна. Он широко использовался в конструкции пресс-форм Have Mould.

6. Наука и управление информацией

Scientific management makes Essai Mold develop in the direction of timely manufacturing and lean production. Make enterprise management more accurate and greatly improve production efficiency.

7. Multi-station progressive die

Multi-position progressive die can complete multiple stamping processes of parts, including stamping, bending, drawing and partial separation and continuous forming. The mold must have a high-precision guidance and positioning system, and be equipped with automatic feeding, automatic output, safety detection, and other devices. Although the mold structure is complex, it has many inserts, the mold manufacturing precision is high. And the manufacturing and assembly process is difficult. It is an important representative of technology-intensive automotive molds.

CNC Automotive Mold Industry

With the advent of electric vehicles, driverless technology, and new energy vehicles, energy-saving, environmental protection, and artificial intelligence, and automotive networking technologies have become increasingly important in the automotive industry. The rapid development of the new energy vehicle market has led to an increase in new models, which has brought huge market opportunities for the mold industry.

Поскольку в транспортных средствах на новой энергии делается упор на снижение потребления энергии и эффективное использование энергии, легкие материалы имеют большой потенциал на рынке. Например, TESLA Model S, 95% алюминиевый сплав на конструктивных частях кузова. Достаточно увидеть, что применение новых материалов в легком весе стало одним из основных технических направлений будущего. Особенно разработка легкого металлического литья и полимерных материалов. Формование и литье компаундов.

Пресс-форма для автомобильной электроники

At the same time, with the rapid development of automotive networking technology and the continuous improvement of electrification and intelligence, automotive electronics molds have also ushered in a wider market space. China's automotive electronics mold companies are actively deploying automotive networking services and key components and high value-added products such as integrated circuits, forming a synergy with the automotive electronics industry. In the context of the rapid development of new energy vehicles and smart cars. They can use molds to make intelligent driving interactive car products. This will provide huge development space for high-end functional components!

Automatic 2 Since 2001, the global mold industry has been growing steadily, with an average growth rate of more than 5%. By 2012, the global mold industry market reached $ 94.5 billion. In the United States, Germany and Japan, and other developed countries. Their automotive-related mold demand accounts for more than 40% of the total mold demand. On this basis, the global automotive mold market has reached 37 billion U.S. dollars. According to the ratio of the output value of automotive stamping dies to 40% of the output value of automotive molds, the global automotive stamping mold market is approximately 15 billion U.S. dollars. At present, North America, Europe, and Japan, as the traditional automotive stamping die demand markets, still occupy an important position in global demand, and their market demand growth rates will remain relatively stable in the next few years.

Rapid Development of the Automotive Industry

The stable and rapid development of the automotive industry has created a good environment for the development of the automotive stamping mold industry. In the production process of automobiles, more than 90% of parts need to be formed by molds. Manufacturing a car requires more than 1,000 to 1,500 sets of stamping dies. The production of a country's cars to some extent reflects the overall condition of the country's auto molds. After the 2008 financial crisis, the auto output of traditional car producers. Such as the United States, Germany, and Japan showed a moderate recovery. However, demand in emerging markets such as China, India, and Brazil has grown rapidly. It is expected that from 2013 to 2020, the global light vehicle production growth rate will reach 3.6%. Among them, the growth rate of developing countries and automotive molds will reach 5.7%.