Automobil

2020-03-21What is CNC Automotive?

The CNC automotive parts industry is the foundation and an important part of the development of the auto industry. The vehicle has about 30,000 parts. They can be divided into automotive engine system parts, body system parts, chassis system parts, electrical and electronic equipment, and general parts according to their functions. According to the material classification, it can be divided into metal parts and non-metal parts. Among them, metal parts account for about 60% -70%, and non-metal parts account for about 30% -40%.

CNC automotive molds refer to molds used in the automotive field. They are called "mothers of the automotive industry." More than 90% of parts in automobile production rely on mold forming.

Generally, a car requires more than 1,000 to 1,500 sets of stamping dies. It accounts for about 40% of the total car output value. There are about 800 sets of plastic molds, about 300 pairs of sheet metal molds and about 100 sets of die-casting molds. Automobile stamping dies are important technical equipment for automobile production. Their design and manufacturing time accounted for about two-thirds of the entire car development cycle. They became one of the main constraints. Automobile stamping dies have the characteristics of large size, complicated working surfaces, and high technical standards, and are technology-intensive products.

CNC-Automobilanwendungen

Das automatische Stempeln von 1 Automobilen bezieht sich hauptsächlich auf die Werkstücke mit der erforderlichen Form und Größe. Diese Werkstücke werden durch Verformen oder Trennen des Metallmaterials von der durch eine äußere Kraft extrudierten Stanzform erhalten. Weit verbreitet in Autoabdeckungen, Karosseriesystemen, Sitzsystemen, Instrumentensystemen und Abgassystemen. Karosserieteile sind fast alle Stanzteile, und Stanzteile für Kraftfahrzeuge sind die nachgelagerte Industrie für CNC-Automobilformen.

Das Stempeln auf der Karosserie ist grob in Abdeckplatten, Trägerplatten und gewöhnliche geprägte Platten unterteilt. Das Siegel, das die Eigenschaften eines Autos klar darstellen kann, ist eine Fahrzeugverkleidung. Daher kann eine spezifischere Automobilform als "Automobilblechprägeform" bezeichnet werden. Genau wie eine Autoform.

Large and medium-sized automobile cover molds are an important part of body manufacturing technology and a key link in forming the independent development capability of automobiles. Automotive mold products include automobile cover molds, tire molds, plastic inner and outer molds, automotive lighting molds, automotive bumper molds and instrument panel molds.

Automotive Mold Market Development

With the increase in the development of new passenger vehicle models, the number of new models introduced has increased year by year. With the growth of the automotive market and the intensification of competition in the automotive market, the capacity of the automotive mold market will grow rapidly in the future. This is also the result of the rapid development of the automotive industry and the rapid development of new models.

Luo Baihui, secretary-general of the International Model Association, said that the market demand for automotive panel molds mainly depends on the number of new models to be launched each year, and the number of new models to be delivered mainly depends on the development of new models. Passenger cars (including cars with less than 9 seats, MPV, SUV, and minibus, etc.).

Car Cover Mold Level

Entsprechend der Kategorie der Abdeckungsteile und den Anforderungen der Automobilhersteller können Autoabdeckungsformen in drei Ebenen unterteilt werden: Low-End, Mid-End und High-End. Unter ihnen ist das Angebot an Formen mit geringem technischen Gehalt überversorgt und die Gewinnspanne des Marktes ist gering. Der Wettbewerb auf dem mittleren Formenmarkt wird immer härter, und hochwertige Formen mit hohem technologischen Gehalt sind weit davon entfernt, die Marktnachfrage zu befriedigen, und der Entwicklungsraum ist riesig.

Bei der Herstellung von CNC-Automobilformen hat Essai Mould ein eigenes Automobilformsystem entwickelt.

1. Automatisches 3D-Design

From a design perspective, the manufacturing of high-end automotive stamping molds requires a parametric design of the molds. We need to combine software template technology to actively and effectively conduct secondary development to form a series of fixed, standardized design parameters, design templates, and achieve complete correlation and drive of parameters. By changing the parameters of the mold parts, quickly change the CAE results, mold process, and optimize the structure of the mold.

2. Simulating Stamping Process-Computer Aided Engineering (CAE)

The manufacture of automotive molds is inseparable from effective plate forming simulation software, and high-end automotive molds require full-process finite element simulation technology. An effective plate forming simulation software can improve the success rate of high-end automotive mold development and greatly shorten the manufacturing cycle of high-end automotive mold development. It can simulate and analyze the formability of automotive stamping parts, determine the difficulty of forming, and the key areas prone to stamping quality defects.

On the other hand, it can also calculate the roughness of automotive stamping parts. Secondly, it can also be used for selective and targeted simulation analysis of the structure and process plan of automotive molds. In addition, it can also provide quantitative analysis and judgment for the debugging of automobile molds. Data, determine feasible debugging solutions and provide specific technical parameters for the solutions. In short, the finite element simulation of the entire process can iteratively optimize the structure and process plan of automotive molds. In addition, we can use various simulations. It can be used to quantitatively analyze and verify the feasibility and reliability of automotive mold design before the on-site mold debugging, to optimize and improve the mold design in time.

3. Digital mold technology

Digital automobile mold technology mainly includes the following aspects: 1. Design for manufacturability (DFM). Consider and analyze manufacturability during the design process to ensure the process success. 2, mold surface design assistance technology, the development of intelligent profile design technology. 3. CAE assists in analyzing and simulating the stamping process, predicting and solving possible defects and forming problems. 4. Replace the traditional two-dimensional design with the three-dimensional mold structure design. 5. The mold manufacturing process uses CAPP, CAM and CAT technologies. 6 Under the guidance of digital technology, solve the problems in the process of test mold processing and stamping production.

4. Mold processing automation

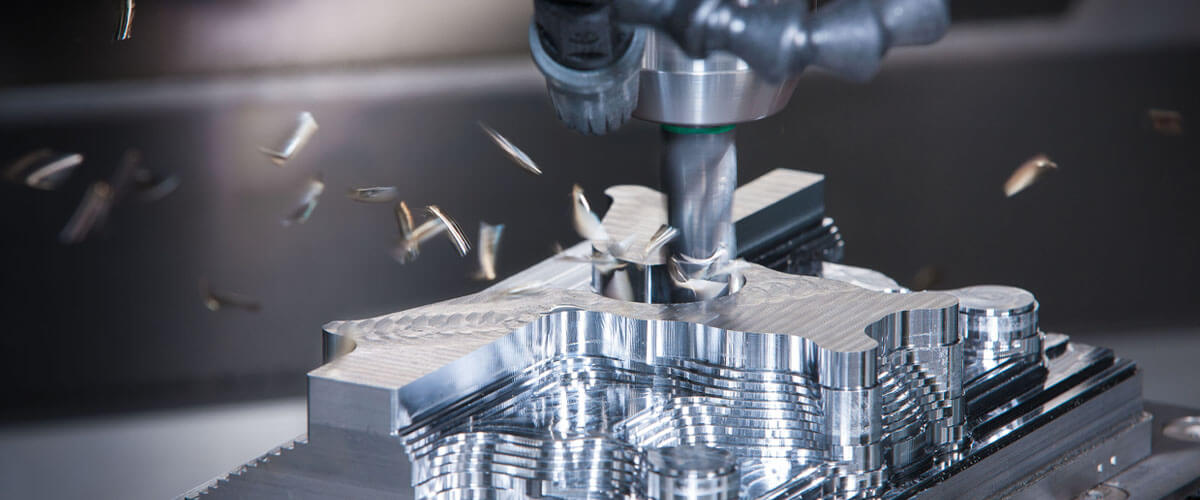

Equipped with a CNC machine with two tables and an automatic tool changer (ATC). They are both optoelectronic control systems for automatic machining and online measurement systems for workpieces. CNC machining has evolved from simple contour machining to complete machining of contours and structural surfaces, from medium-speed machining to low-speed machining to high-speed machining.

5. Mold material and surface treatment technology

The quality and performance of mold materials are important factors affecting mold quality, life and cost. Ductile iron has good toughness and wears resistance, welding performance, workability and surface hardening performance. Moreover, the cost is lower than the alloy cast iron. It has been widely used in Have Mould's mold design.

6. Science and information management

Durch das wissenschaftliche Management entwickelt sich Essai Mould in Richtung einer zeitnahen Herstellung und einer schlanken Produktion. Machen Sie das Unternehmensmanagement genauer und verbessern Sie die Produktionseffizienz erheblich.

7. Progressive Matrize mit mehreren Stationen

Progressive Matrizen mit mehreren Positionen können mehrere Stanzvorgänge von Teilen ausführen, einschließlich Stanzen, Biegen, Ziehen und teilweiser Trennung sowie kontinuierliches Formen. Die Form muss über ein hochpräzises Leit- und Positionierungssystem verfügen und mit automatischer Zuführung, automatischer Ausgabe, Sicherheitserkennung und anderen Geräten ausgestattet sein. Obwohl die Formstruktur komplex ist, viele Einsätze aufweist, ist die Präzision bei der Herstellung der Form hoch. Und der Herstellungs- und Montageprozess ist schwierig. Es ist ein wichtiger Vertreter technologieintensiver Automobilformen.

CNC Automobilindustrie

With the advent of electric vehicles, driverless technology, and new energy vehicles, energy-saving, environmental protection, and artificial intelligence, and automotive networking technologies have become increasingly important in the automotive industry. The rapid development of the new energy vehicle market has led to an increase in new models, which has brought huge market opportunities for the mold industry.

Da neue Energiefahrzeuge auf Energieeinsparung und effiziente Energienutzung Wert legen, haben leichte Materialien ein großes Potenzial auf dem Markt. Zum Beispiel TESLA Model S, 95% Aluminiumlegierung auf den Karosserieteilen. Es genügt zu sehen, dass die Anwendung neuer Materialien im Leichtbau in Zukunft zu einer der wichtigsten technischen Richtungen geworden ist. Insbesondere die Entwicklung von Leichtmetallformteilen und Polymermaterialien Formen und Verbundformen.

Kfz-Elektronikform

Gleichzeitig haben mit der rasanten Entwicklung der Automobil-Netzwerktechnologie und der kontinuierlichen Verbesserung von Elektrifizierung und Intelligenz auch Formen der Automobilelektronik einen größeren Marktraum eröffnet. Chinas Formenhersteller für Automobilelektronik setzen aktiv Netzwerkdienste und Schlüsselkomponenten für die Automobilindustrie sowie Produkte mit hohem Mehrwert wie integrierte Schaltkreise ein und bilden so eine Synergie mit der Automobilelektronikindustrie. Im Kontext der rasanten Entwicklung neuer Energiefahrzeuge und intelligenter Autos. Sie können Formen verwenden, um intelligentes Fahren interaktive Autoprodukte herzustellen. Dies bietet enormen Entwicklungsraum für hochwertige Funktionskomponenten!

Automatic 2 Since 2001, the global mold industry has been growing steadily, with an average growth rate of more than 5%. By 2012, the global mold industry market reached $ 94.5 billion. In the United States, Germany and Japan, and other developed countries. Their automotive-related mold demand accounts for more than 40% of the total mold demand. On this basis, the global automotive mold market has reached 37 billion U.S. dollars. According to the ratio of the output value of automotive stamping dies to 40% of the output value of automotive molds, the global automotive stamping mold market is approximately 15 billion U.S. dollars. At present, North America, Europe, and Japan, as the traditional automotive stamping die demand markets, still occupy an important position in global demand, and their market demand growth rates will remain relatively stable in the next few years.

Rapid Development of the Automotive Industry

The stable and rapid development of the automotive industry has created a good environment for the development of the automotive stamping mold industry. In the production process of automobiles, more than 90% of parts need to be formed by molds. Manufacturing a car requires more than 1,000 to 1,500 sets of stamping dies. The production of a country's cars to some extent reflects the overall condition of the country's auto molds. After the 2008 financial crisis, the auto output of traditional car producers. Such as the United States, Germany, and Japan showed a moderate recovery. However, demand in emerging markets such as China, India, and Brazil has grown rapidly. It is expected that from 2013 to 2020, the global light vehicle production growth rate will reach 3.6%. Among them, the growth rate of developing countries and automotive molds will reach 5.7%.