How to learn China CNC machining & Machining CNC Auto Parts skills in 2020?

2020-07-20What is China CNC machining & Machining CNC Auto Parts ?

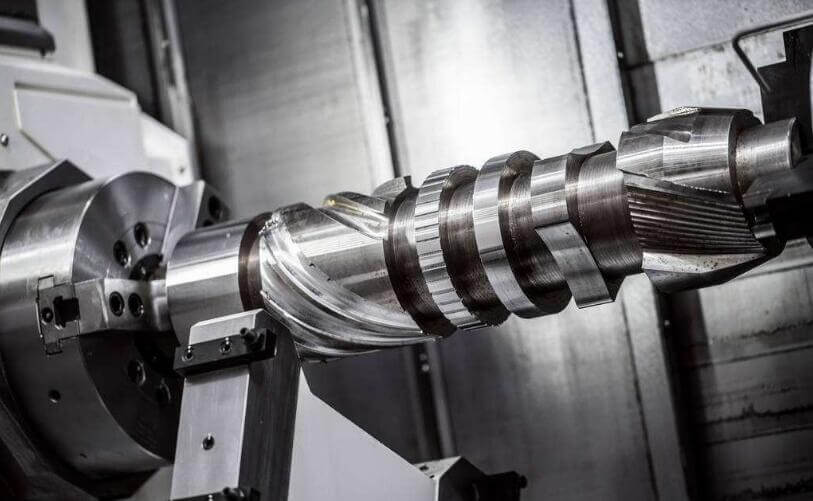

China CNC machining & Machining CNC Auto Parts are basically a procedure of manufacturing the CNC machining parts. And in it manufacturers use computer software that is pre-programmed.

This software actually controls all the movements of factory machinery and tools. And this process generally has the ability to use and control a wide range of complicated machinery. Hence, this CNC machinery can be as follows:

- lathes

- grinders

- routers

- mills

Furthermore, in a single set of hints, for three-dimensional tasks of cutting and fabricating. The manufacturers can consummate CNC machining parts easily with CNC machining. In fact the CNC process works inconsistent with the terms of manual control.

As we know there are some limitations of manual control. That requires operators to guide the following parts of these machining tools immediately. Like:

- Buttons

- Levers

CNC is actually a short form of “computer numerical control”. Visually, CNC machining system may have resemblance with manual set of computer components. But the consoles and software programs in the China CNC machining & Machining CNC Auto Parts have distinguished it from all other different types.

China CNC machining & Machining CNC Auto Parts market cross the 100.9 billion worldwide by 2025

Nowadays, almost all type of industries has made use of CNC machining within their process of manufacturing. And the reason behind it is that, it facilitates a broader and larger scope of applications. When we do a comparison of manually operated machinery with CNC machining.

Another cause of using China CNC machining & Machining CNC Auto Parts is that it boosts and increases the production level.

Furthermore, there is also a wide range of jobs that is enough to surprise you. But in the condition that you are also searching for a flawless career, you must take a deep knowledge about several paths. Hence, by doing so you can easily discover something really beneficial just like CNC machining.

So, with the increasing activity in the industry of China manufacturing, is increasing an in the opportunities of job. Manufacturers are estimating that for upcoming seven years almost 56, ooo jobs are expecting in the field of CNC machining.

And it is the perfect time to research and analyze this most thrilling, rewarding and impressive path of career.

How do përpunimit dhe përpunimit të pjesëve të automjeteve CNCwork?

Kinës work fully automatic. Basically they need only one thing and that is digital files. These digital files actually have all the directions about cutting tooling and trajectories. These machining procedures generally require several instruments in order to generate a specific part.

Manufacturers have the ability to build the libraries of digital tools. These tools actually interact with the physical machine.

This type of machinery has work ability to execute automatically. For working automatically, CNC machines have switch tooling process. And it is based on the digital directions which help them to make manufacturing workhorses.

Furthermore, in these CNC machining & Machining CNC Auto parts operations actually start with the designing parts. And these designing parts have designed in CAD software. The model of 3D actually identifies the necessary elements of the final part like:

- dimensions

- properties

Several programs of this type occur in CAD-CAM packages. So that the overflow can persist in the similar programs. In the condition that CAM and CAD come in similar family of the product, then there is basically no need of any files translations.

On the other hand, these CAD files have the requirement to import. The software of CAM basically develops the model for the entire procedure of fabrication.

There are actually four main parts of this process of fabrication

First:

Kontrollon dhe interpreton për gabimet në modelin e pjesës Kinë CNC & Machining Auto

E dyta:

Ndihmon në krijimin e një programi CNC në mënyrë që të krijohen pjesët fizike të programit.

Shkurtimisht, ky program është një komplet i plotë integrimesh që në fakt i jep udhëzime kokës prerëse në të gjithë procesin e prodhimit.

E treta:

Në hapin e tretë prodhuesit zgjedhin parametrat e duhur dhe të duhur. Dhe në këto parametra janë përfshirë:

- tensionit

- shpejtësia e prerjes

- RPM, etj

Për më tepër, konfigurimi i tij mbështetet plotësisht në pjesën e gjeometrisë dhe së bashku me veglat dhe makineritë e disponueshme.

Pjesa e katërt dhe e fundit kryesore:

Në këtë hap të fundit prodhuesit vendos dhe vendos folezimin përfundimtar. Termi fole në të vërtetë nënkupton vendosjen dhe vendndodhjen e pjesëve përfundimtare në lidhje me materialin e tyre të lidhur. Qëllimi kryesor që qëndron pas tij është, të përdorësh sa më shumë materialin përkatës.

Sa lloje të përpunimit dhe përpunimit të pjesëve të automjeteve CNC ?

Në parim ekzistojnë shumë lloje unike dhe të jashtëzakonshme të përpunimit CNC & të pjesëve të automjeteve . Në shumicën e këtyre makinave, funksionet elementare janë të njëjta. Por ato janë krijuar sipas funksioneve të tyre që duhet të kryejnë.

Këtu po japim disa shembuj të makinave CNC. Këto janë:

- Torno

- Mullinj CNC

- Prerës plazmatik

- Makineritë e shkarkimit elektronik të sinkerit

- Makineri elektronike të shkarkimit të telit

Torno

A lath basically has the ability to cut pieces in the circular direction. The manufacturers in this machine do this special process with the help of indexed tools. Manufacturers use lathes in order to fabricate complex designs. But lathes are basically not complex machines.

Mullinj CNC

Manufacturers run these types of China CNC machining & Machining CNC Auto part with the help of programs. These programs have made hints and that can use the both

- letters

- numbers

These mills mostly use three-axis system. But latest models of these mills are extra complex. And they actually have the ability to operate six-axis system at a time.

Prerës plazmatik

Manufacturers use plasma cutter CNC machines mostly for materials of metal. As they know that these metals need a lot of heat and speed for making precision cuts.

Këtu janë detajet e llojeve të mbetura të Kinës

Makineritë e shkarkimit elektronik të sinkerit

Njihet gjithashtu si EDM sinker. Ata punojnë ashtu si EDM-të e telit. Në këtë proces, ndryshimi është midis asaj se si përdoret energjia elektrike për të hequr copat. Me ndihmën e zhytësit EDM, për qëllim për të kryer prodhuesit e energjisë elektrike thithin materialet e metaleve në një lëng dielektrik.

Për më tepër, në këtë proces të përpunimit dhe përpunimit të pjesës automatike CNC ne shohim se si prodhuesit i formojnë pjesët e metaleve në forma të caktuara.

Makineri elektronike të shkarkimit të telit

Ky lloj është i famshëm edhe me emrin e EDM-ve të telit. Në këtë lloj makinerie prodhuesit përdorin shkëndija elektrike në mënyrë që të formojnë copa në forma të caktuara.

Cilat janë disa nga avantazhet e China CNC machining & Machining CNC Auto parts?

Here we are providing you some helpful advantages of CNC machines and Machining CNC Auto parts.

These are:

- Parts may have customization or alteration

- Higher precision

- Costs of set up are fairly low. so functions can rush and set once again

- Lower inclined to inner stress in comparison to other processes because parts have great physical qualities

- For progress, many changes can be applied easily and smartly inside a manufacturing run

What are the applications for manufacturing China CNC machining & Machining CNC Auto parts?

Engineers build several most familiar Kinës for the purpose of niche procedures of manufacturing.

For instance:

- Electrochemical machining

- Conventional CNC machines

Electrochemical machining:

Manufacturers use these CNC machining in order to cut the products of metals that have great durability.

Conventional CNC machines:

Engineers use these CNC based machines for prototyping.

Why Kinës are necessary?

Since we have learned that operators of CNC machines work and also help in a wide range of fields. So, people from all different stalking are getting benefits from CNC machines.

For example from military groups to hobbyists, people are attaining advantages by these CNC machines to convert raw materials in the final products in a very low cost. Kinës have the following qualities like:

- extra efficient

- faster and quicker

- Më e sigurt