የአሉሚኒየም ማስወጫ በ 7 ቀላል ደረጃዎች (የ 2020 የቅርብ ጊዜ መመሪያ)

2020-10-01 እ.ኤ.አ.What is Aluminum Extrusion: (Profiles Extrusion Guide 2020)

Aluminum extrusion Introduction

Modern computer programs for modeling የአሉሚኒየም are capable of many things. It can effectively improve the quality of extruded aluminum profiles even at the design stage of extrusion dies. Computer modeling allows improving the quality of produced aluminum profiles according to the following indicators:

- dimensional accuracy and profile shape

- strength and appearance of welds

- grain microstructure of material

- mechanical properties of the material

What is aluminum extrusion definition?

Below is an overview of the የአሉሚኒየም process. It is intended as an initial introduction to this technology for press production technicians and may also be useful as information for management and support personnel.

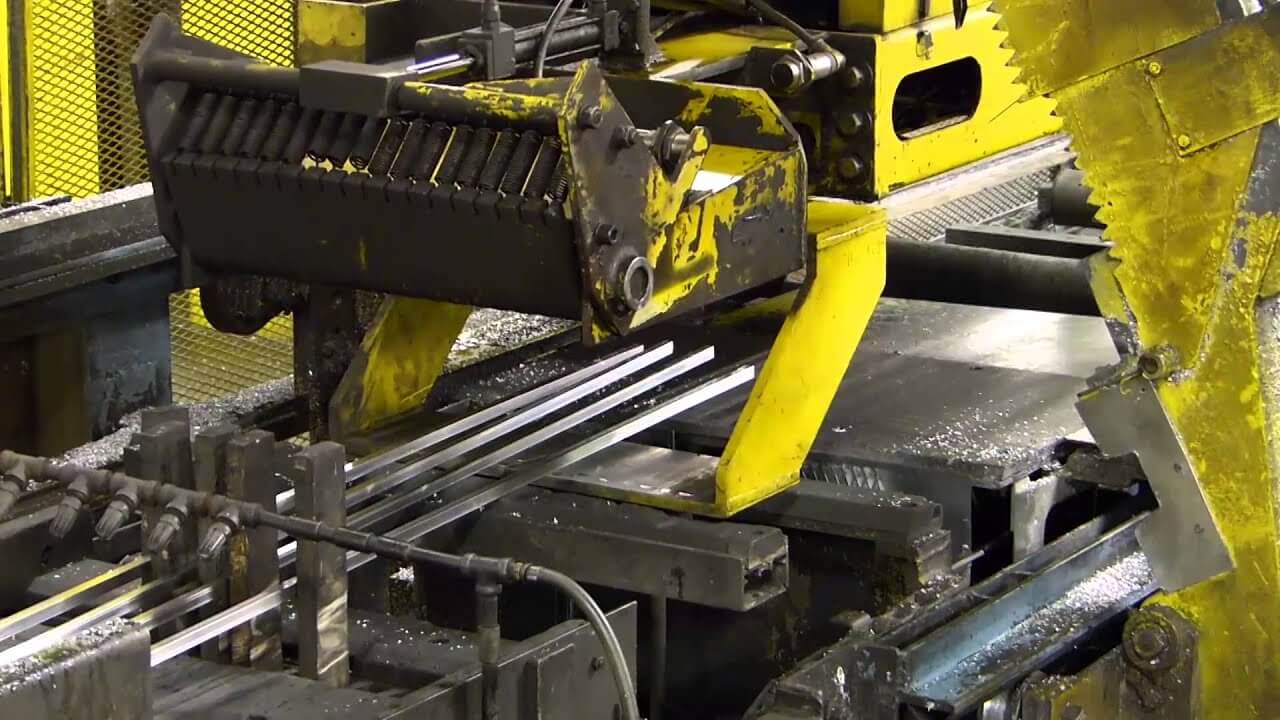

Extrusion press

Aluminum cylindrical rods - blanks - are heated and pressed through a die with one or more holes. We carry this process to obtain a profile with a given cross-section. The most common type of pressing is direct pressing. When the ram of the press pushes the aluminum blank through a stationary die.

Most of the presses for this technology are horizontal hydraulic presses. The productivity of the press depends on the size of the dies used. It can have a diameter of 100 to 1000 mm. For most extruded aluminum products, matrices with a diameter of 175 to 250 mm are used. For dies of this diameter, የአሉሚኒየም presses with a force of 1500 to 2000 tons are required.

Aluminum Extrusion process step by step guide

- The ram transfers the force from the main cylinder of the extrusion press to the aluminum billet. It is loaded into the container.

- A steel press washer is installed on the ram. The press washer fits into the container with a very small gap to prevent aluminum from being squeezed into the container.

- The matrix is part of the matrix set. It is made of heat-resistant tool steels.

- The spacer bolster and die holder and die set holder support the die under the influence of pressing force.

- A feeder can be installed in front of the die to expand the aluminum flow from the container to a wider area of the die.

Aluminum extrusion pressing without lubrication

Since no lubricant is used in direct pressing of aluminum, the outer layer of the workpiece is sheared off under the influence of friction against the container wall. This has a beneficial effect on the quality of extruded aluminum products.

The fact is that the outer layer of cast billets has an increased content of iron-containing intermetallic particles and Mg 2 Si particles. These contaminants can be sources of surface defects on the finished የአሉሚኒየም product. In direct pressing without lubrication, they accumulate at the end of the workpiece.

Press residue and cross weld

This part of the blank, called the press residue, is cut off before the new blank is loaded into the press. During the next working stroke of the press, aluminum from a new billet under the influence of high pressure. And increased temperature is welded to aluminum from the previous billet.

በማትሪክስ ውስጥ ቀረ ፡፡ ይህ ቀጣይነት ያለው የተጣራ የአልሙኒየም ምርት ይፈጥራል ፡፡ ሁለት ተጎራባች የመስሪያ ዕቃዎች የሚገጣጠሙበት ቦታ ተሻጋሪ ዌልድ ተብሎ ይጠራል ፡፡ በዚህ ስፌት አቅራቢያ ያለው መገለጫ ሜካኒካዊ ባህሪያትን ስለቀነሰ ብዙውን ጊዜ ተቆርጦ እንደገና ለማቅለጥ ይላካል ፡፡

የሥራውን ክፍል ማሞቅ እና የመጫኛ መሣሪያ

Before loading into the press, the የአሉሚኒየም የማስወጫ ሂሳብ በቅይሉ ላይ በመመርኮዝ እስከ 400-500 heated ይሞቃል ፡ ይህ የተበላሸውን ሂደት ያመቻቻል እና የአሉሚኒየም ጥንካሬን ማቃለልን ይቀንሰዋል። የተሞቀው የሥራ ክፍል በፕላስቲክ ሁኔታ ውስጥ ነው ፡፡

The container and die are also heated to prevent the workpiece from getting colder. The dimensions of the die opening are made slightly larger than the cross-sectional dimensions of the finished extruded profile. Since during cooling, aluminum shrinks more than the tool steel from which the matrix is made.

Aluminum extrusion types

The most widely used types of dies for የአሉሚኒየም are:

- flat (solid) dies and

- porthole dies.

Flat dies consist of only one steel flat disc and are used to press solid profiles.

Porthole matrices consist of:

- two parts

- a matrix disk and

- a mandrel part.

This allows you to press hollow profiles and semi-hollow profiles. Both types of dies can have several pressing channels. So that several identical profiles can be pressed simultaneously.

Flat matrix

የጠፍጣፋ ማትሪክስ በጣም አስፈላጊ ባህሪዎች-

- የቅድመ-መኝታ ቤት ፣ በሚሠራው ቀበቶ ፊት ለፊት ኪስ; አስፈላጊ በሚሆንበት ጊዜ ይተገበራል;

- የሥራ ቀበቶ

- ማስፋፊያ መውጫ

የሥራ አንገት የአሉሚኒየም ፡ የሚሠራው አንገት በጠቅላላው የሞቱ ውፍረት ውስጥ አይዘልቅም ፣ ግን 15 ሚሜ ወይም ከዚያ ያነሰ ርዝመት አለው ፡፡ ይህ የሚያስፈልገውን የመጫን ኃይል ለመቀነስ ነው ፡፡

የማትሪክስ እየሰፋ የሚወጣው የውጤት ክፍል ለሠራው ቀበቶ አስፈላጊውን የኃይል ድጋፍ መስጠት ነው ፡፡ ነገር ግን ከማትሪክስ ከሚወጣው አልሙኒየም ጋር ሳይገናኝ መደረግ አለበት ፡፡ ለዚህም የመውጫ ክፍሉ ግድግዳዎች በ 5º ገደማ በሆነ ማእዘን ይሰራሉ ፡፡ እና በተጨማሪ ፣ ብዙውን ጊዜ ከሚሠራው ቀበቶ በስተጀርባ የተወሰነ ጠርዝ አለው ፡፡

በአሉሚኒየም ማስወጫ ውስጥ የፕሪምበርበር ተግባር ምንድነው?

The function of a special pocket in የአሉሚኒየም የፕሬስ ቅሪቶችን በሚለይበት ጊዜ “ተሰባሪ” የሚሠራውን ባንድ ከጉዳት መጠበቅ ነው ፡ እና ቀጣዩን የ workpiece ማትሪክስ ውስጥ ከሚቀጥለው workpiece ጋር ብየዳ ለማመቻቸት ነው ፡፡ በተጨማሪም ቅድመ-ንጣፍ የአሉሚኒየም ፍሰትን ለመቆጣጠር እንደ መሣሪያ ጥቅም ላይ ይውላል ፡፡

የፖርትሆል ማትሪክስ

ቀደም ሲል እንደተጠቀሰው ሁለት ክፍሎችን ይ ,ል ፣

- ማትሪክስ ዲስክ

- እና አንድ mandrel ክፍል

የአንደሩ ክፍል የአሉሚኒየም ፕሮፋይል ውስጣዊ ቅርፅን ከሚፈጥሩ የሥራ ቀበቶዎች ጋር አንድ ወይም ብዙ መንደሮች ሊኖረው ይችላል ፡፡ ድልድዮች በድልድዮች አማካኝነት ከማንዶር አካል ጋር የተገናኙ ናቸው ፡፡

Aluminum streams flow around these bridges through feed holes and re-join in welding chambers. The final shaping of the profile takes place simultaneously on the working bands of the mandrel and the matrix disk.