Aluminium extrusie in 7 eenvoudige stappen (2020 nieuwste gids)

2020-10-01What is Aluminum Extrusion: (Profiles Extrusion Guide 2020)

Aluminum extrusion Introduction

Modern computer programs for modeling aluminium extrusieproduct are capable of many things. It can effectively improve the quality of extruded aluminum profiles even at the design stage of extrusion dies. Computer modeling allows improving the quality of produced aluminum profiles according to the following indicators:

- dimensional accuracy and profile shape

- strength and appearance of welds

- grain microstructure of material

- mechanical properties of the material

What is aluminum extrusion definition?

Below is an overview of the aluminium extrusieproduct process. It is intended as an initial introduction to this technology for press production technicians and may also be useful as information for management and support personnel.

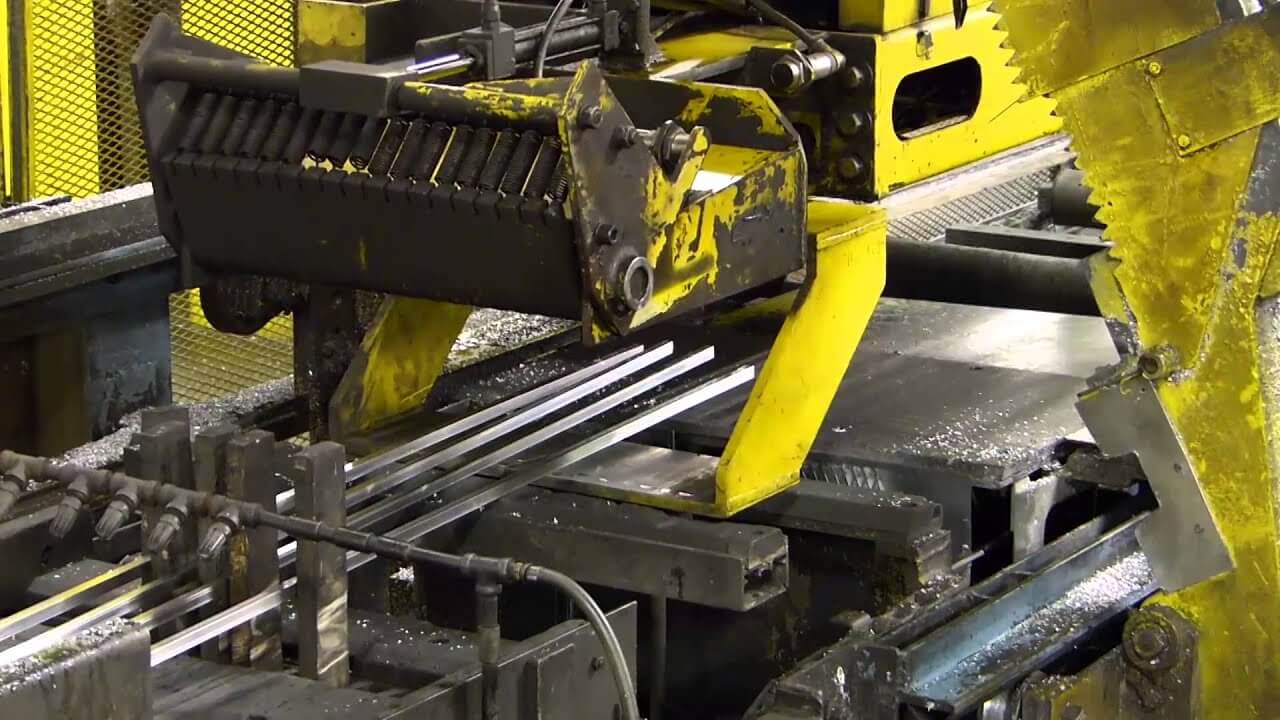

Extrusion press

Aluminum cylindrical rods - blanks - are heated and pressed through a die with one or more holes. We carry this process to obtain a profile with a given cross-section. The most common type of pressing is direct pressing. When the ram of the press pushes the aluminum blank through a stationary die.

Most of the presses for this technology are horizontal hydraulic presses. The productivity of the press depends on the size of the dies used. It can have a diameter of 100 to 1000 mm. For most extruded aluminum products, matrices with a diameter of 175 to 250 mm are used. For dies of this diameter, aluminium extrusieproduct presses with a force of 1500 to 2000 tons are required.

Aluminum Extrusion process step by step guide

- The ram transfers the force from the main cylinder of the extrusion press to the aluminum billet. It is loaded into the container.

- A steel press washer is installed on the ram. The press washer fits into the container with a very small gap to prevent aluminum from being squeezed into the container.

- The matrix is part of the matrix set. It is made of heat-resistant tool steels.

- De afstandsbolster en matrijshouder en matrijzensethouder ondersteunen de matrijs onder invloed van drukkracht.

- Voor de matrijs kan een feeder worden geïnstalleerd om de aluminiumstroom van de container naar een groter gebied van de matrijs uit te breiden.

Aluminium extrusiepersen zonder smering

Omdat bij het direct persen van aluminium geen smeermiddel wordt gebruikt, wordt de buitenste laag van het werkstuk onder invloed van wrijving tegen de houderwand afgeschoven. Dit heeft een gunstig effect op de kwaliteit van geëxtrudeerde aluminiumproducten.

Feit is dat de buitenste laag van gegoten knuppels een verhoogd gehalte aan ijzerhoudende intermetaaldeeltjes en Mg 2 Si-deeltjes heeft. Deze verontreinigingen kunnen bronnen zijn van oppervlaktedefecten op het afgewerkte aluminium extrusieproduct . Bij direct persen zonder smering hopen ze zich op aan het einde van het werkstuk.

Pers residu en kruislas

Dit deel van de blanco, het persresidu genoemd, wordt afgesneden voordat de nieuwe blanco in de pers wordt geladen. Tijdens de volgende werkslag van de pers wordt onder invloed van hoge druk aluminium uit een nieuwe knuppel gehaald. En verhoogde temperatuur is gelast aan aluminium van de vorige staaf.

It remained in the matrix. This creates a continuous extruded aluminum product. The place where two adjacent workpieces are welded is called a transverse weld. Since the profile near this seam has reduced mechanical properties, it is usually cut out and sent for remelting.

Heating of the workpiece and pressing tool

Before loading into the press, the aluminium extrusieproduct billet is heated to 400-500 ºС, depending on the alloy. This facilitates the deformation process and minimizes the strain hardening of aluminum. The heated workpiece is in a plastic state.

The container and die are also heated to prevent the workpiece from getting colder. The dimensions of the die opening are made slightly larger than the cross-sectional dimensions of the finished extruded profile. Since during cooling, aluminum shrinks more than the tool steel from which the matrix is made.

Aluminum extrusion types

The most widely used types of dies for aluminium extrusieproduct are:

- flat (solid) dies and

- porthole dies.

Flat dies consist of only one steel flat disc and are used to press solid profiles.

Porthole matrices consist of:

- two parts

- a matrix disk and

- a mandrel part.

This allows you to press hollow profiles and semi-hollow profiles. Both types of dies can have several pressing channels. So that several identical profiles can be pressed simultaneously.

Flat matrix

The most important characteristics of a flat matrix are:

- forechamber , pocket in front of the working belt; applies when necessary;

- work belt

- expanding outlet

The work collar is the part of the aluminium extrusieproduct on which the aluminum gets its final shape. The working collar does not extend through the entire thickness of the die, but has a length of 15 mm or less. This is to minimize the required pressing force.

The function of the expanding output part of the matrix is to provide the necessary power support to the working belt. But it should be done without contact with aluminum emerging from the matrix. For this, the walls of the outlet part run at an angle of about 5º. And, in addition, it usually has some ledge just behind the working belt.

What is the function of prechamber in aluminum extrusion?

The function of a special pocket in aluminium extrusieproduct is to protect the "fragile" working band from damage when separating the press residue. And it is also to facilitate welding of the remainder of the workpiece in the matrix with the next workpiece. In addition, the prechamber is used as a means of controlling the aluminum flow.

Porthole matrix

As already mentioned, it consists of two parts,

- a matrix disk

- and a mandrel part

The mandrel part can have one or several mandrels with working belts that form the inner contour of the aluminum profile. The mandrels are connected to the mandrel body by means of bridges.

Aluminiumstromen stromen rond deze bruggen door voedingsgaten en komen weer samen in laskamers. De uiteindelijke vormgeving van het profiel vindt gelijktijdig plaats op de werkbanden van de doorn en de matrixschijf.