Cómo comprender los conceptos básicos de los moldes de plástico

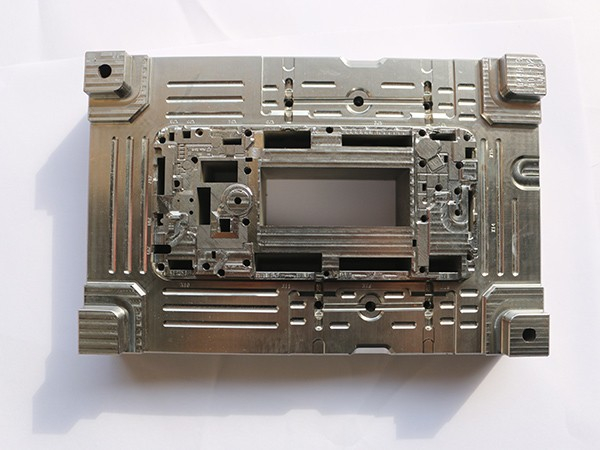

2020-03-23El molde de plástico incluye una cavidad con una cavidad variable compuesta por un sustrato de combinación de cavidades, un componente de cavidad y una tarjeta de combinación de cavidades. Una matriz convexa con un núcleo variable compuesto por una placa compuesta de sección lateral. El procesamiento de moldes de plástico juega un papel importante en el lanzamiento de nuevos productos industriales. Hoy, Jiehui Chuangxiaobian te llevará a comprender algunos conocimientos básicos de moldes de plástico.

1. Synthetic resin is the main component of plastic, and its content in plastic is generally 40% to 100%. Because the content is large, and the nature of the resin often determines the nature of plastic, people often regard resin as a synonym for plastic. For example, polyvinyl chloride resin and polyvinyl chloride plastic, phenolic resin and phenolic plastic are mixed. In fact, resin and plastic are two different concepts. Resin is an unprocessed virgin polymer that is not only used to make plastics, but also a raw material for coatings, adhesives, and synthetic fibers. In addition to a very small proportion of plastics containing 100% resin, most plastics, in addition to the main component resin, need to add other substances.

2. Filler Filler is also called filler, which can improve the strength and heat resistance of plastics and reduce costs. For example, adding wood powder to phenolic resin can greatly reduce the cost, making phenolic plastic one of the cheap plastics, and at the same time, it can significantly improve the mechanical strength. Fillers can be divided into two types: organic fillers and inorganic fillers, the former such as wood flour, rags, paper and various fabric fibers, and the latter such as glass fiber, diatomite, asbestos, carbon black and the like.

3. Plasticizer Plasticizer can increase the plasticity and softness of plastic, reduce brittleness, and make plastic easy to process. Plasticizers are generally high-boiling organic compounds that are miscible with resins, non-toxic, odorless, and stable to light and heat. Phthalates are commonly used. For example, when producing polyvinyl chloride plastics, if more plasticizers are added, soft polyvinyl chloride plastics can be obtained. If no or less plasticizers are added (dosage <10%), rigid polyvinyl chloride plastics can be obtained. .

4. Stabilizers In order to prevent synthetic resins from being decomposed and destroyed by light and heat during processing and use, and extend the service life, stabilizers must be added to plastics. Commonly used are stearates and epoxy resins.

5. Colorantes Los colorantes pueden hacer que los plásticos tengan varios colores brillantes y hermosos. Los tintes orgánicos y los pigmentos inorgánicos se utilizan comúnmente como colorantes.

6. Lubricante La función del lubricante es evitar que el plástico se adhiera al molde de metal durante el moldeado y, al mismo tiempo, hacer que la superficie del plástico sea suave y hermosa. Los lubricantes de uso común son el ácido esteárico y sus sales de calcio y magnesio. Además de los aditivos anteriores, se pueden añadir al plástico retardadores de llama, agentes espumantes, agentes antiestáticos, etc.