How to understand the basics of plastic molds

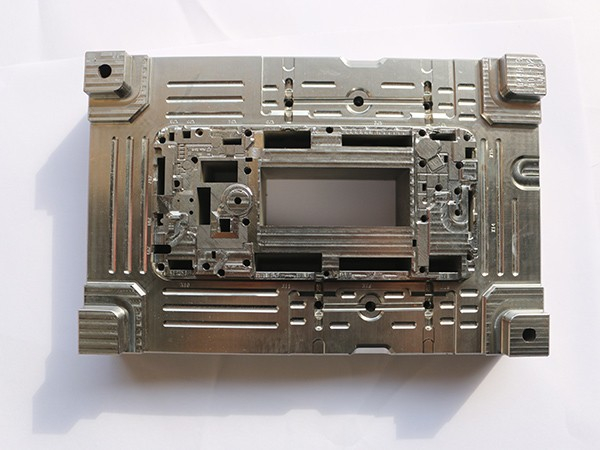

23-03-2020The plastic mold includes a cavity with a variable cavity composed of a cavity combination substrate, a cavity component, and a cavity combination card. A convex die with a variable core composed of a side-section composite plate. Plastic mold processing plays an important role in the release of new industrial products. Today Jiehui Chuangxiaobian will take you to understand some basic knowledge of plastic molds.

1. Synthetic resin is the main component of plastic, and its content in plastic is generally 40% to 100%. Because the content is large, and the nature of the resin often determines the nature of plastic, people often regard resin as a synonym for plastic. For example, polyvinyl chloride resin and polyvinyl chloride plastic, phenolic resin and phenolic plastic are mixed. In fact, resin and plastic are two different concepts. Resin is an unprocessed virgin polymer that is not only used to make plastics, but also a raw material for coatings, adhesives, and synthetic fibers. In addition to a very small proportion of plastics containing 100% resin, most plastics, in addition to the main component resin, need to add other substances.

2. Filler Filler is also called filler, which can improve the strength and heat resistance of plastics and reduce costs. For example, adding wood powder to phenolic resin can greatly reduce the cost, making phenolic plastic one of the cheap plastics, and at the same time, it can significantly improve the mechanical strength. Fillers can be divided into two types: organic fillers and inorganic fillers, the former such as wood flour, rags, paper and various fabric fibers, and the latter such as glass fiber, diatomite, asbestos, carbon black and the like.

3. Plasticizer Plasticizer can increase the plasticity and softness of plastic, reduce brittleness, and make plastic easy to process. Plasticizers are generally high-boiling organic compounds that are miscible with resins, non-toxic, odorless, and stable to light and heat. Phthalates are commonly used. For example, when producing polyvinyl chloride plastics, if more plasticizers are added, soft polyvinyl chloride plastics can be obtained. If no or less plasticizers are added (dosage <10%), rigid polyvinyl chloride plastics can be obtained. .

4. Stabilizers In order to prevent synthetic resins from being decomposed and destroyed by light and heat during processing and use, and extend the service life, stabilizers must be added to plastics. Commonly used are stearates and epoxy resins.

5. Kleurstoffen Kleurstoffen kunnen ervoor zorgen dat kunststoffen verschillende heldere en mooie kleuren hebben. Organische kleurstoffen en anorganische pigmenten worden vaak als kleurstoffen gebruikt.

6. Smeermiddel De functie van het smeermiddel is om te voorkomen dat het plastic tijdens het gieten aan de metalen mal blijft kleven en tegelijkertijd het oppervlak van het plastic glad en mooi te maken. Veelgebruikte smeermiddelen zijn stearinezuur en zijn calcium- en magnesiumzouten. Naast bovenstaande toevoegingen kunnen vlamvertragers, schuimmiddelen, antistatische middelen etc. aan de kunststof worden toegevoegd.