Penggilingan CNC

CNC Milling adalah untuk mengontrol bagian-bagian eksekusi melalui PLC di bawah instruksi kontrol yang dikeluarkan oleh sistem CNC untuk menyelesaikan pemrosesan bagian-bagian. Saat membuat bagian, untuk memastikan toleransi berbagai bentuk dan posisi sesuai dengan persyaratan gambar, analisis proses harus dilakukan. Yang pertama adalah menentukan teknologi proses pemesinan benda kerja, dan melakukan analisis proses, pemilihan metode penjepitan, dan penentuan jumlah pemotongan. Alat itu dipilih lagi. Kemudian program rute pemesinan. Pertimbangkan poin-poin berikut sebelum menentukan proses milling CNC:

1. Pastikan akurasi pemesinan dan kualitas permukaan suku cadang, dan efisiensinya tinggi.

2. The shortest possible processing route, reducing idle travel time and tool changing times and improving productivity.

3. Reduce the deformation of parts.

4. Make the calculation of numerical points as convenient as possible and shorten the programming work time.

5. Reasonably choose the CNC milling method to improve the processing quality of the part.

6. Reasonably select the starting point, cut-in and cut-out points of the tool and the cut-in and cut-out methods of the tool to ensure the smoothness of the cutting and cutting of the tool. The processing of whole parts with high position accuracy should avoid the position error caused by the backlash of the machine tool.

7. The processing of complex curved parts should be determined according to the actual shape, accuracy requirements, processing efficiency and other factors of the part.

8. Ensure the safety of the machining process and avoid interference between the tool and the non-machined surface.

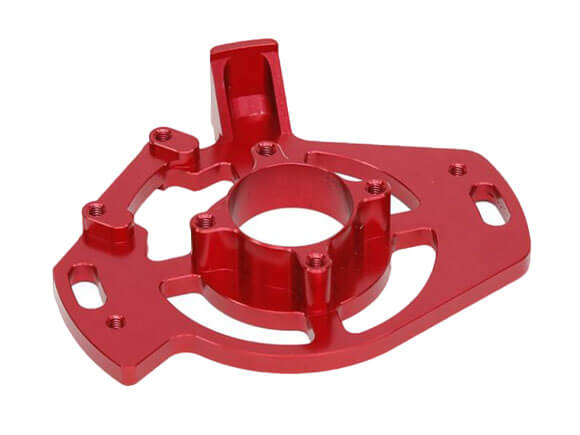

Established offers a range of CNC Milling processes to produce precise and complex parts with high-dimensional tolerances:

- Carving Machine

- CNC Three-Axis

- CNC Four-Axis

- CNC Five-Axis

- Milling Machine/End Milling

- Gantry Milling