CNC Milling

CNC Milling processing is to control the execution parts through PLC under the control instructions issued by the CNC system to complete the processing of parts. When manufacturing parts, in order to ensure the tolerances of various shapes and positions according to the requirements of the drawing, a process analysis must be performed. The first is to determine the machining process technology of the workpiece, and to carry out process analysis, choice of clamping method, and determination of cutting amount. The tool was selected again. Then program the machining route. Consider the following points before determining the CNC milling process:

1. Ensure the machining accuracy and surface quality of parts, and the efficiency is high.

2. The shortest possible processing route, reducing idle travel time and tool changing times and improving productivity.

3. Reduce the deformation of parts.

4. Make the calculation of numerical points as convenient as possible and shorten the programming work time.

5. Reasonably choose the CNC milling method to improve the processing quality of the part.

6. Reasonably select the starting point, cut-in and cut-out points of the tool and the cut-in and cut-out methods of the tool to ensure the smoothness of the cutting and cutting of the tool. The processing of whole parts with high position accuracy should avoid the position error caused by the backlash of the machine tool.

7. The processing of complex curved parts should be determined according to the actual shape, accuracy requirements, processing efficiency and other factors of the part.

8. Ensure the safety of the machining process and avoid interference between the tool and the non-machined surface.

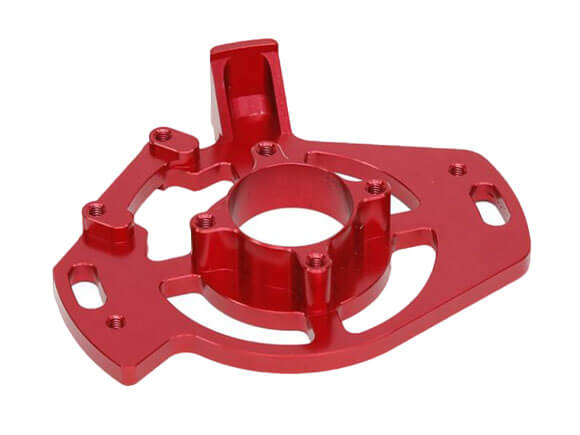

Established offers a range of CNC Milling processes to produce precise and complex parts with high-dimensional tolerances:

- Carving Machine

- CNC Three-Axis

- CNC Four-Axis

- CNC Five-Axis

- Milling Machine/End Milling

- Gantry Milling