Top Effective Tips for Grind and Welding Process

2020-08-25How to Make the Grind and Welding Process Effective and Efficient?

Despite all the technological advancement and automation, the grind and welding process is and will likely remain an intensively manual operation. When rubber comes in contact with the road, the concept is grinding. Or to be more precise it is when the grain comes in contact with the metal.

그라인딩은 간단한 과정으로 보일 수 있지만 효과적인 결과를 얻으려면 세부 사항에주의를 기울여야합니다. 이 과정은 올바른 천사들에게 적절한 압력을 가할 것을 요구합니다. 이렇게하면 단시간에 대부분의 금속을 제거 할 수 있습니다.

부품의 원활한 흐름에 효과적인 몇 가지 변수가 있습니다. 얼마나 빠르고 업그레이드 된 업스트림 공정을 사용하든 연삭 부서를 통과하는 데 몇 달이 아니라면 하루가 걸릴 것입니다.

이 주제는 매우 광범위합니다. 그러나 연삭 작업의 성공을 보장하기 위해 가장 효과적인 몇 가지 팁을 제공합니다. 이러한 요소는 몇 가지 초기 아이디어를 제공합니다.

연마 및 용접 공정의 성공을 보장하는 방법

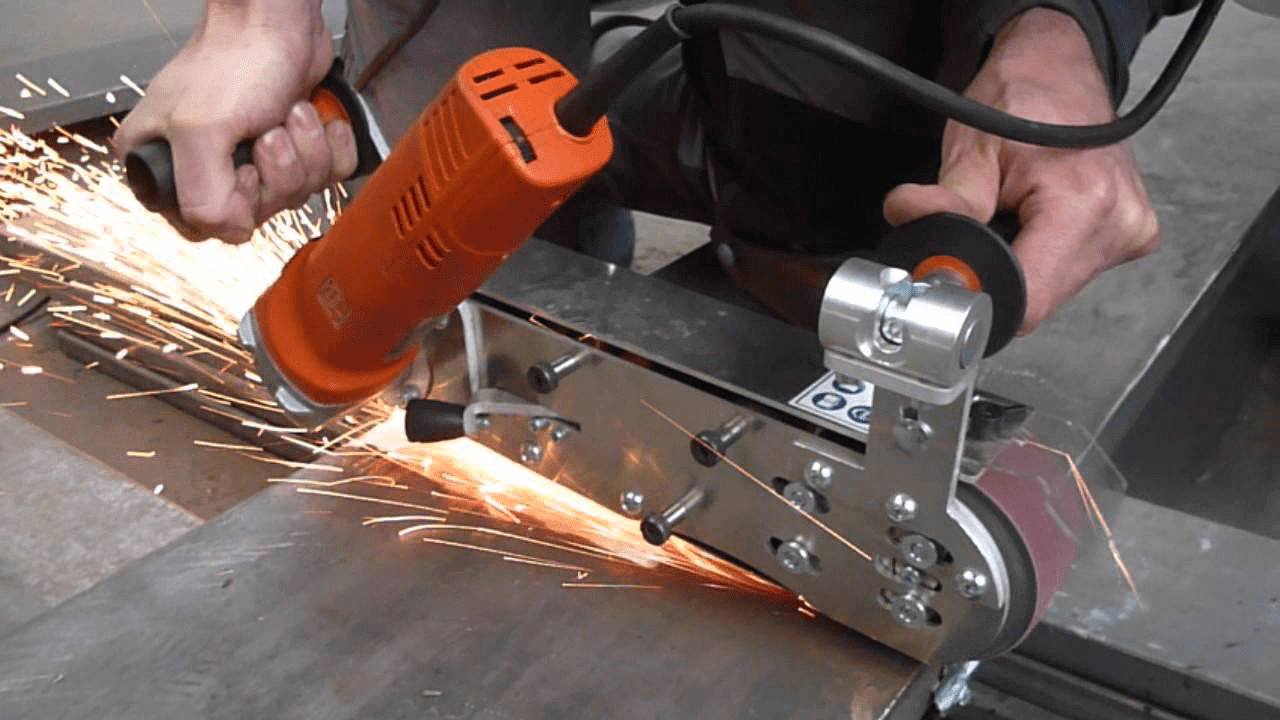

올바른 도구

전동 공구가 그라인딩 디스크처럼 소모품이 아닌지 확인하십시오. 따라서 그라인더에 관해서는 신중해야합니다. 실제로 작업의 암페어를 적절하게 처리 할 수있는 것을 선택하십시오.

예를 들어, 애플리케이션에 8 ~ 10A의 압력이 필요하고 6A, 직각 그라인더를 선택하는 경우. 우리는 처음부터 문제가 있음을 확신 할 수 있습니다. 프로세스가 진행됨에 따라 상황은 더 나빠질 것입니다.

그라인더는 버릴 수있는 도구가 아니므로 투자를 적극 권장합니다. 임의의 그라인더를 선택하는 대신 고급 산업용 레벨 그라인더를 사용하십시오. 거의 두 배의 비용이 들지만 작동 수명을 몇 주가 아닌 몇 년으로 측정 할 수 있습니다.

Both the flap discs and the grinding discs are compatible with the right-angle grinders. Combining a low-quality grinder would high-quality grinding discs would yield better results. However, it would lack the smoothness of premium quality grinders and grinding discs.

Safety Comes First

When you use the right tool for the job, it automatically ensures safe operations. For instance, using a grinder without guarding would open doors to a lot of potential injuries. Also, if the OSHA figures this, the company would have to pay a hefty fine.

Yes, we understand that the guard can be troublesome in some situations. However, without the guards, things can get serious. Things would become even worse if you are using the wrong tool or you are underpowered.

So, if you are planning to grind in the tight areas, removing your guard and squeezing in the right-angle grinder is not the way to go about it. Use the file grinder. It would be the right tool to guarantee job efficiency and accuracy.

Before you change the abrasive media, it is important to unplug the tool. When changing the media, we recommend using the power tool’s head in order to lock the key button. Put the tool on your forearm, facing upwards. Now take your time and remove the abrasive.

Performing these steps would offer more control during abrasive changeout. In addition, it won’t allow the abrasive to drop. After all, dropped abrasive is among the commonly overlooked reason behind abrasive failure.

Also, the fall of the disc during a high-RPM right angle grinder can lead to some serious damage. You need to be extra careful as the smallest crack can make the discs lose during the operation. Too often the operators are putting back the disc after it drops out. Of course, they do inspect it first, but this is not a reliable and safe solution.

Spark Flow

Limited shops do have an ammeter at hand. It is a tool that you can use to keep a close check on the operator. It lets you determine whether the operator is pushing too hard or it is taking things lightly. It is possible to alter the change depending upon the grinding wheel and the tool.

Optimal pressure for the industrial grinding application ranges between eight to ten amps. In case, the ammeters show reading above this range, you need to slow down. However, if it shows below that range, you need to gear up.

Unfortunately, not all shops have ammeter at hand. Therefore, you need an alternative. The good news almost all applications produce sparks during the grind and welding process. Manufacturers use these sparks as an indication of the pressure. These sparks act as a visual ammeter.

Wondering how the sparks can help determine whether the process is working effectively or not? In most cases, the sparks would flow about three to four feet away from the work-place. If you find the sparks not following this particular pattern it means you are either overdoing it or underdoing it.

When you push too hard, it would overheat and overload the disc. This would result in the grains to glaze over. They would then become smooth. Since the grains are no longer cutting into the weld, therefore there would be spark reduction.

Likewise, when you are not pushing enough, you are not fully engaging in the workplace. Every disc rotation would not yield enough weld metal.

Pay heed to the Grinder Sound

The grinder’s sound is another effective way to figure out the problem. Applying the right pressure would produce a sound that has a contact pitch. In case, you are underdoing, the pitch volume would increase. In the case of overdosing, there would a drop in the volume.

The Right Working Angle of Grind and Welding Process

일반적으로 연마 디스크는 수평으로 5 ~ 10도 각도로 사용해야합니다. 또한 디스크 표면에 존재하는 패턴은 두께의 두 배 여야합니다. 예를 들어 패턴 폭이 0.5 인치 인 경우 디스크 두께는 0.25 인치 여야합니다.

디스크 두께가 0.25”인데 마모 패턴이 0.75”이고 접근 방식이 평평하다면. 각도 접근이 적절하지 않다는 것을 의미합니다. 특히 여러 연삭 디스크의 입자가 서로 맞 물릴 때 너무 높습니다.