Petua untuk memperbaiki reka bentuk Prototaip Lembaran Logam | 2020

2020-06-09Bagaimana cara memperbaiki Reka Bentuk Prototaip Logam Lembaran?

Prototaip Lembaran Logam telah menjadi bahagian penting dalam industri moden. Sekiranya kita mengatakan bahawa kedua-dua fabrikasi dan prototaip logam lembaran adalah bahagian belakang industri, kita tidak akan salah. Prototaip ini sangat penting dalam aeroangkasa, automotif, dan beberapa industri lain.

Manufacturers around the globe have been using sheet metal for manufacturing parts like chassis, panels, enclosures, brackets, appliance, and panels. To ensure the quality of the product, it is important to have a strong and high-quality sheet metal prototype.

The quality of these parts would make a great difference. Moreover, having the right and error-free sheet metal design is important. After all, the correct design would add to the robustness of the prototype.

This blogpost would focus on some important tips to improve the design of your sheet metal prototype.

Tips to Improve Sheet Metal Prototype Design

There are several factors that need consideration. These factors play an important role when it comes to defining the quality of the prototype. For starters, it is important that you partner with a professional and experienced prototyping manufacturer such as the Essaii .

A reasonable and accurate design holds great importance as well. If the design meets the required expectation, only then will it serve its purpose to perfection. The design lacking its ability to meet the requirement, you eventually cause the downfall of its respective product.

According to researches, manufacturers spend about 30% of their time fixing the problems that were in the design. The reworking of the parts leads to heavy, but thanks to modern prototyping, this all can be resolved at a minimal cost and within budget.

There is no denying the importance of correct design, achieving it is a different story. Here are some effective designs tips that would improve the overall quality of your prototyping.

Clear Design Purpose

It is crucial for engineers and designers to have a clear purpose for their design. In addition, they need to have a proper plan in place to make sure that the sheet metal design is easy for the manufacturer as well as cost-effective.

Several factors need consideration during the designing phase including the thickness, mechanical properties, function, tooling methods, features, and tolerance. All these factors need to be in accord with the actual application.

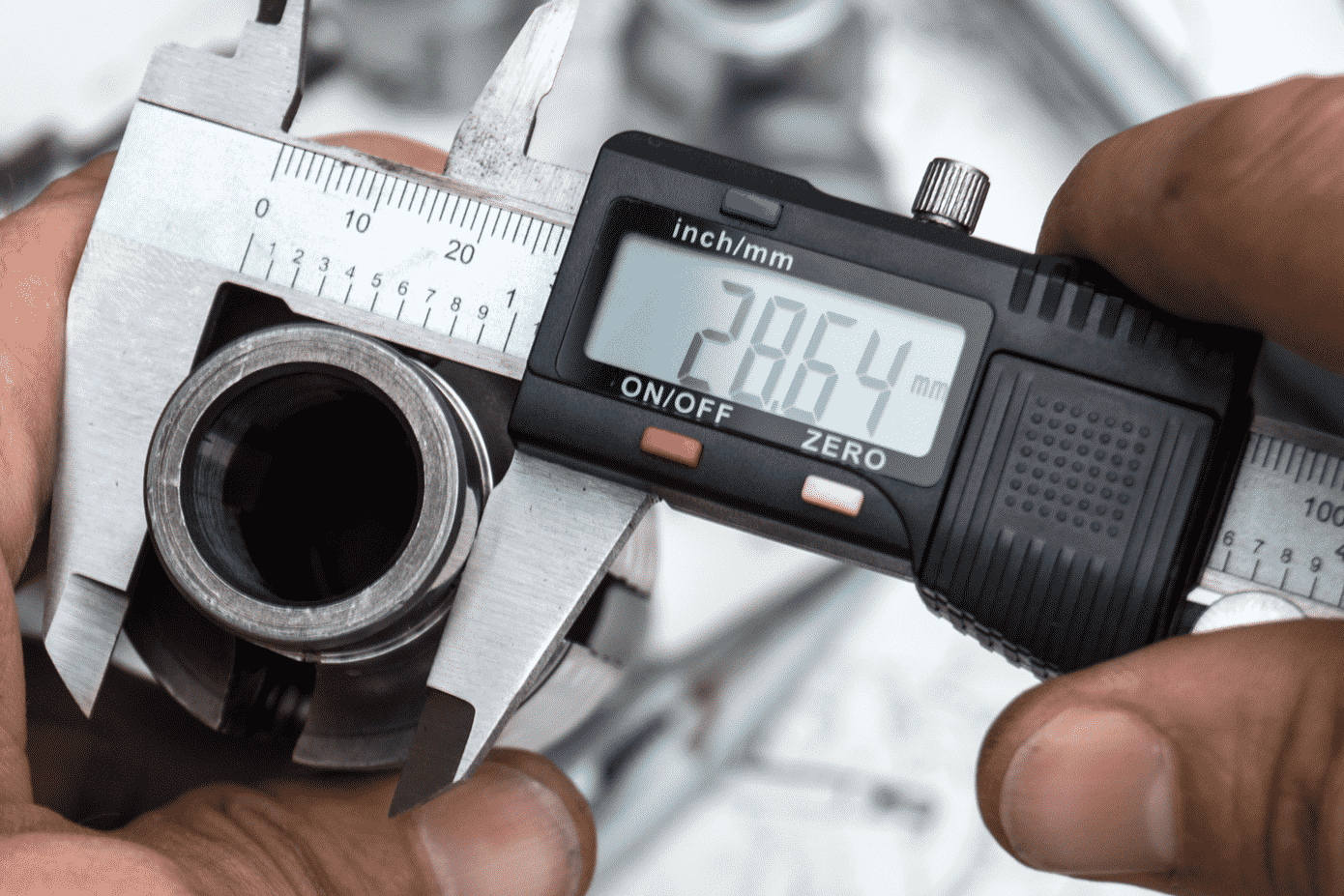

Focus on Sheet Metal Prototyping Hole Designs

Manufacturers mostly use sheet metal to make a metal prototype. They understand that the sheet metal would need slots for screw, holes, interlocking sections, bolts, among others. These things would be part of the design.

The engineers would specify the size, alignment, positions of the holes during the design phase. All these things are extremely important. Below, are some rules that you should follow:

Sheet Thickness

It is important that the thickness of the sheet is less in comparison to the hole’s diameter. A thicker sheet would lead to higher punch loading, something you would want to avoid. In addition, it would require excessive burr and a longer time to burnish. Also, a thick sheet would lead to slug-pulling. Thus, having an adverse impact on the metal sheet’s punch and lifespan.

Hole Spacing

Another important rule that you need to follow is having the right spacing between holes. A good rule of thumb is to have space equaling to twice the thickness of the sheet between each hole. After all, the correct spacing between holes ensure the robustness of the metal sheet, as well as prevents its deformation. It also prevents the bending process.

Holes on the Edge

When you are incorporating holes on the edges of the sheet, make sure that the correct spacing. For these holes, the space between every hole should at least equal to the thickness of the sheet.

The right Partner

When you partner with the right prototyping manufacturer, you are less likely to make mistakes in the design phase. After all, they experienced and knowledgeable staff would be there to ensure a mistake-proof steel metal prototyping design.

Manage Tolerance

For a metal sheet, tolerance is important. Therefore, as an engineer, you need to pay close attention to this aspect of prototyping. When we talk about managing tolerance, you need to understand that it is just not one element that requires attention.

On the contrary, there are several factors that come into play. For instance, the material, features, thickness, function along with the capability of the prototyping manufacturer. It is vital to consider the die accuracy, along with the wear during the punching process.

You also need to pay heed to the fabrication process. After all, this process is majorly responsible for turning the sheet into prototypes and parts. The spacing between parts also has an impact on tolerance. So, the designers need to focus on this aspect as well.

Zero Clearance

Sekiranya terdapat jarak sifar antara bahagian, ia akan menyebabkan penolakan toleransi. Oleh itu, ia akan menyebabkan bahagian kepingan selesai, namun tidak sesuai dengan bahagian lain semasa pemasangan. Ini adalah sesuatu yang perlu dielakkan dengan segala cara.

Pilihan Perkakas

Perkakas memainkan peranan penting, bagaimanapun, mereka menentukan bentuk prototaip logam lembaran. Sebagai contoh, selekoh garis lurus adalah masalah biasa dengan tol brek tekan konvensional. Jadi, berbentuk kepingan menggunakan alat ini berakhir dengan selekoh garis lurus.

Walau bagaimanapun, jika anda ingin mencapai kos terendah, maka idea yang baik adalah mengekang reka bentuk anda menggunakan bentuk tertentu ini. Begitu juga, jika anda berminat dengan ciri-ciri yang lebih terperinci, idea yang baik adalah menggunakan penekan.

Ia menawarkan ciri-ciri seperti tombak jambatan, counterersink bulat timbul dan banyak lagi. Sekiranya berlaku pukulan, kami menawarkan ukuran standard. Juga, dari segi kos, alat ini adalah pilihan terbaik. Apabila anda memilih pengeluar berpengalaman seperti Essaii , anda akan mendapat akses ke peralatan canggih.

Catatan: Apabila anda menggunakan konfigurasi alat biasa, ia akan menjimatkan banyak wang berbanding dengan alat khusus bahagian.

Prototaip Logam Lembaran

Dalam pembuatan logam lembaran, lenturan sangat penting. Terima kasih kepada teknologi moden dan canggih, dapat menjadikan logam lembaran rata menjadi sebilangan bentuk. Walau bagaimanapun, anda perlu mengikuti sekumpulan peraturan tertentu untuk mengelakkan kekurangan dalam reka bentuk bahagian lenturan logam lembaran.

Sinaran

It is extremely important to ensure that the radius of the inside bend is not more than the sheet metal’s thickness. Doing so will stop any sort of deforming in the future.

Consistent Bending Direction

Another rule that you really do to focus is to guarantee that the bending direction is consistent. With consistent bending direction, along with the correct bending radius, it is possible to cost fabrication. Also, the overall cost of making parts would come down.

Proper Bend Designing

Instead of relying on exclusive parts machines, it is a good idea to design bends while keeping in mind the standard forming process and tools. Doing this would ensure that the bends are cost-efficient as well as effective.

On the other hand, when you use specialized bending tools, it not only increases the cost significantly but also slows down the manufacturing process.

Bawa pulang

Following the above rules would improve the sheet metal prototyping design. Of course, a flawless design would lead to an error-less prototype and eventually to a successful product. However, to achieve this there are several factors that require consideration, robustness, weight, component assembling, and much more.

NOTE: If your sheet metal prototype is of a complex design, the above rules might not be effective.

In addition to focusing on all these elements, you also need to join hands with a reliable manufacturing partner. Essaii is among the leading steel metal prototype manufacturer. They will provide complete assistance from scratch. Their vast experience in the industry allows them to deliver high-quality, yet cost-efficient prototypes.

For further information, reach out to them on Essaii.