Can You Really Afford Custom Aluminum Extrusion?

2020-08-25Factors that Contribute Towards the Cost of Custom Aluminum Extrusion

If you think that custom aluminum extrusion is not affordable, you have been interacting with the wrong kind of manufacturers. You need proper planning to get custom extrusion not only on time but also within budget.

Despite steel being the common choice across industries, aluminum is becoming popular with the passing time. After all, it has a lot more to offer. It ensures corrosions resistance, durability, strength, weight, numerous finishing options and low maintenance.

What more is that with aluminum, architects and product designers are able to acquire destinations that might seem like a dream in case of steel. Aluminum contributes significantly to the sustainability efforts, after all, it is among the most recycled materials in the industry.

Aluminum Extrusion: Important Elements

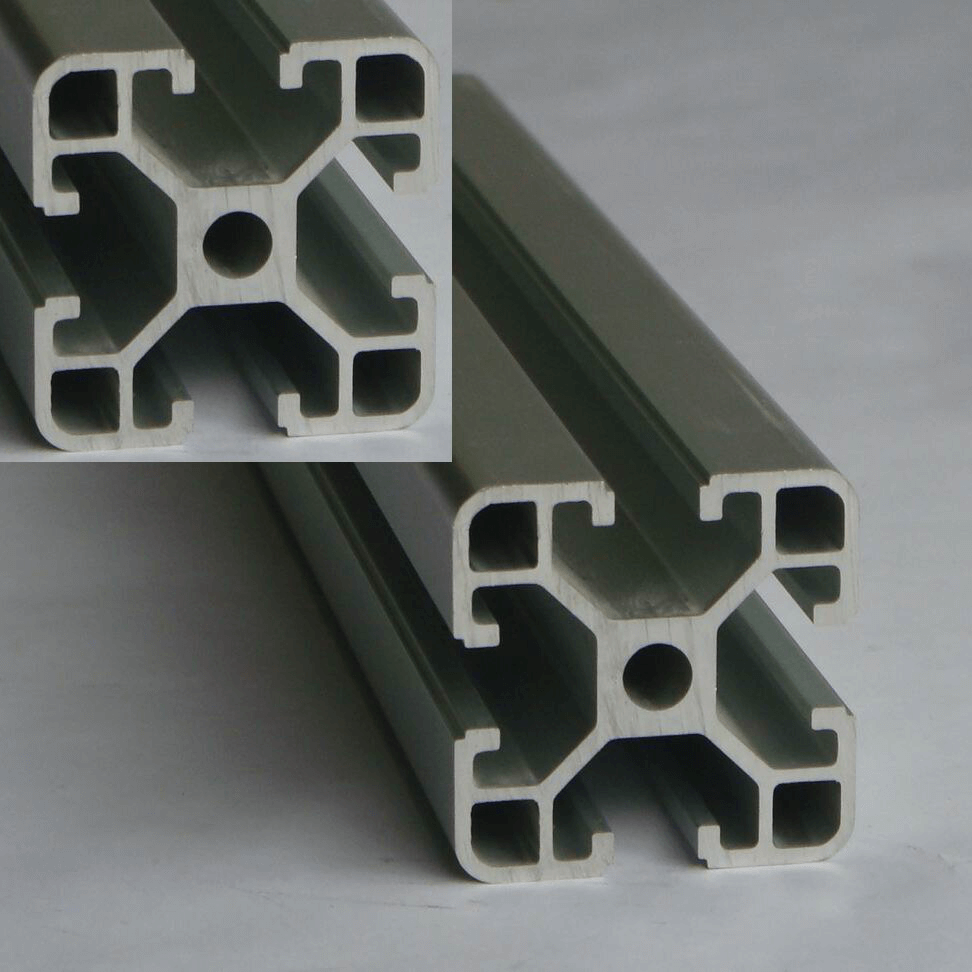

Funding and feasibility are the two major factors that govern the custom aluminum extrusion. These after all a matter of the circle size along with the required weight of the shape per linear foot. Although, the combination sounds extremely complicated.

However, we can assure you that it is fairly easy to grasp. In simple terms, it is the ratio between the profile size and the thickness of the material. Sine the extrusion presses different in terms of their capability, finding the one that suits you best is the matter of looking around.

For instance, if you have a profile that has a section area ranging between 1 to 2.5 square inches and it has a diameter that is 1 to 10. Finding an aluminum extruder for this particular profile would not be a challenging task. Since it lacks complexity, most extruders would be able to do a good job.

On the contrary, if you want a profile that requires a circumscribed circle greater than 14 inches, dia and the cross section is greater than 10 square inches. This is something challenging and only experienced extruder such as the Essaii would be able to handle it with perfection.

Cost Factors

Die is the major contributor to the cost of the extrusion process. You would likely have to pay for 1000 of dollars for the die. However, this cost is not significant when compared to the entire architectural project.

In addition, in most cases, the lead times are usually less than a month. So, these factors would contribute the custom extruding’s affordability. For example, the revisions required, or the full-scale prototyping.

Other factors adding to the project cost include the custom-made check-fixtures along with the tools that are required for the bending machine. In order to cut down the overall custom extrusion expense, you should consult an experienced and relevant extruder.

Design Guidelines

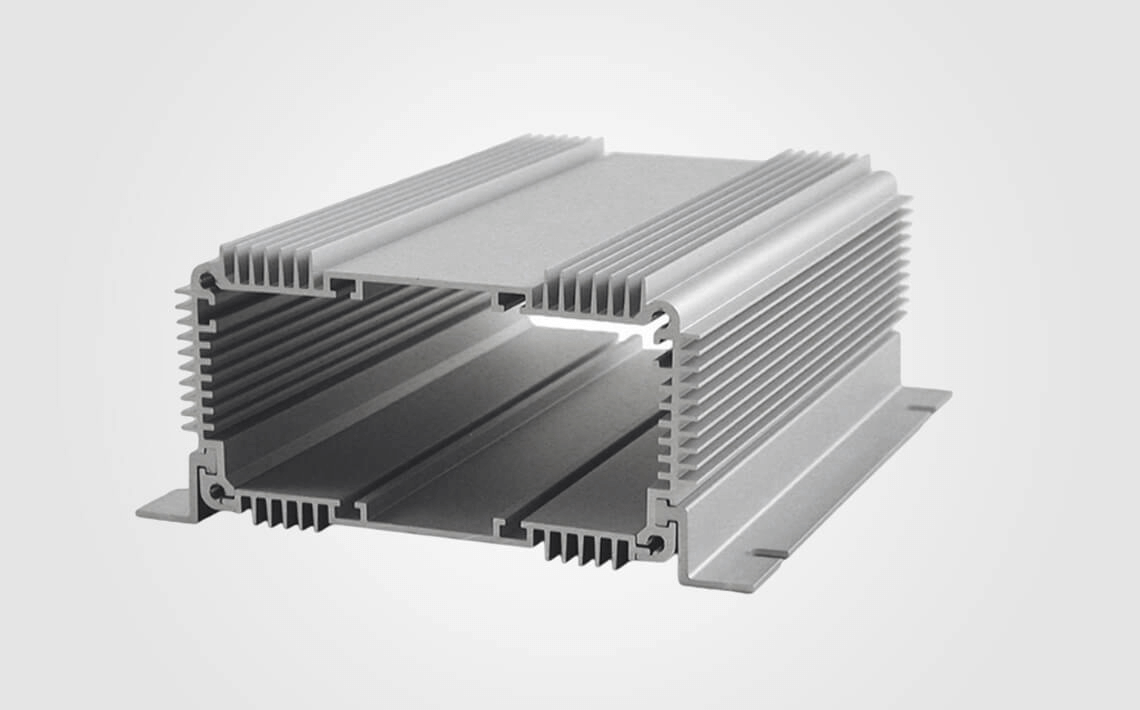

Even though the extruded shapes have some limitations, yet they do offer design freedom and substantial versatility. Since custom aluminum extrusion is creating a new profile form the scratch instead of purchasing off-the-shelf profile, therefore you have different options.

It is up to you to choose the dimensions, shape, structure and other aspects of the aluminum profile. Below is a basic table for guide design.

Alloy Selection

When it comes to alloy selection, aluminum offers a wide variety of tempers and alloys. For instance, for the construction and building applications, manufacturers would recoomend the 6XXX series. Even though some other alloys may offer greater strength.

However, 6XXX series is excellent for electrical conductivity. It has the best combination of properties for the construction business. Alloys to consider are 6005A, 6061, 6063, and 6060.

Profile Design

When you reach out to an experienced custom aluminum extrusion manufacturer, you would get read input on the profile design. Reaching out to an extruder is imperative if you are new to extrusion. You will be surprised to know that small differences in the design can lead to significant reduction in terms of cost.

For starters, you need to think out of the box. We agree that I, C, L and rectangle work well for several application, but then you don’t need custom aluminum extrusion. You will be able to find most of these shapes right off-the-shelf.

Next, it is important to keep the design simple to ensure the success of execution while keeping a firm hold onto the cost. See some effective tips below.

- Use gentle radii and corners.

- Keep tongues as shallow and as wide as possible

- Ensure uniform thickness of the walls.

- Design while having symmetry in your mind.

When we say unique, we don’t mean complex. By unique, we mean a design that serves the purpose while being eye-catching and bold.

Surface Specifications and Tolerances

You easily find the industry-standard tolerances online. However, a good and reliable custom aluminum extrusion manufacturer would ensure tolerance higher than the industry standards. After all, they plan to delivery only the best.

So, a good way to go about this is to talk to your extruder. They would be able to provide you with the required information as well as how the acquiring the standards would impact your overall cost. At this stage, you should also discuss the project visibility as well as the surfaces that are associated with these particular areas.

Structural Considerations

There is no denying that creating optimal structure is more than one-time cycle. It is an iterative process that starts with the functions. It then moves through a number of forms, joining methods and geometry considerations.

For start, you should consult the aluminum design manual. It consists of the aluminum basis for the construction as per the international building standards along with aluminum structures specifications.

Custom Aluminum Extrusion offers Different Finishing

Once you extrude, the aluminum promptly creates a tenacious oxide film. The purpose of this film is to provide additional protection against corrosion. In most cases, you won’t require additional finishing.

However, if you want to enhance the physical appearance or sever service conditions, you would need additional finishing. Do bear in mind that the additional finishing would increase the cost. So, do these finishing only when they are a must.

To further know how this finishing would impact your project cost, you should talk to your extruder. They are the best source to acquire authentic and reliable information.