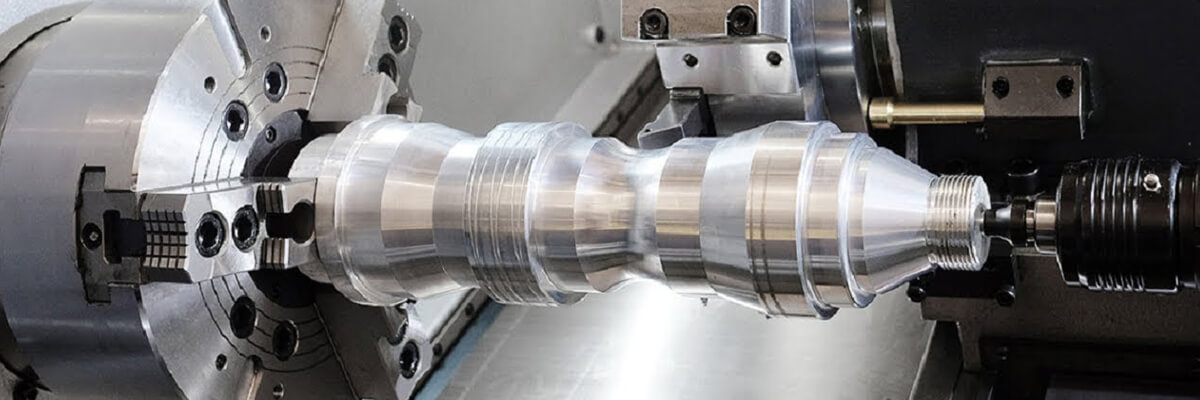

Tornio CNC tornio lavorazione parti meccaniche

- Live tooling

- All metals/alloys

- Multiple spindle

- +/- 0.0003" tolerance

- Y-axis milling operations

When you need CNC turning with high precision, please ask us for help. Essai offers you high quality CNC turnings in a variety of industries.

CNC Turning Machine is an intricate and detailed method of creating custom parts and components using a lathe. Computer Numerical Control (CNC) turning is a highly-skilled, Precision Engineering process. Based on one of the oldest machine tools in the world – the lathe – turning in its traditional form can be traced back to ancient Egypt.

Through modern computer technology and skilled operators, a component can now be created to the minutest detail and to the most rigid of designs using a Turning Lathe, with precise tolerances and a vast array of shapes. The turning lathe secures and rotates the stock, or raw material, being machined along a dual-axis of movement at high speeds, while a single-point cutting or boring tool shapes the material, resulting in the desired component being created. The lathe is controlled by computer programs; ensuring meticulously exact components are produced, and can also be reproduced. At Essai, we pride ourselves on being experts in the latest CNC Turning Technology and Processes, and on our ability to create the components our customers demand swiftly, efficiently and precisely.

Lavorazione CNC

Often turning and milling are generically referred to as “CNC machining” – our customers often ask for CNC machining rather than for turning or milling by name. Of course, it’s our job to make sure that the most appropriate process is used each time.

Put simply, the difference between the two processes comes down to which part moves – in general terms, the metal or the machine.

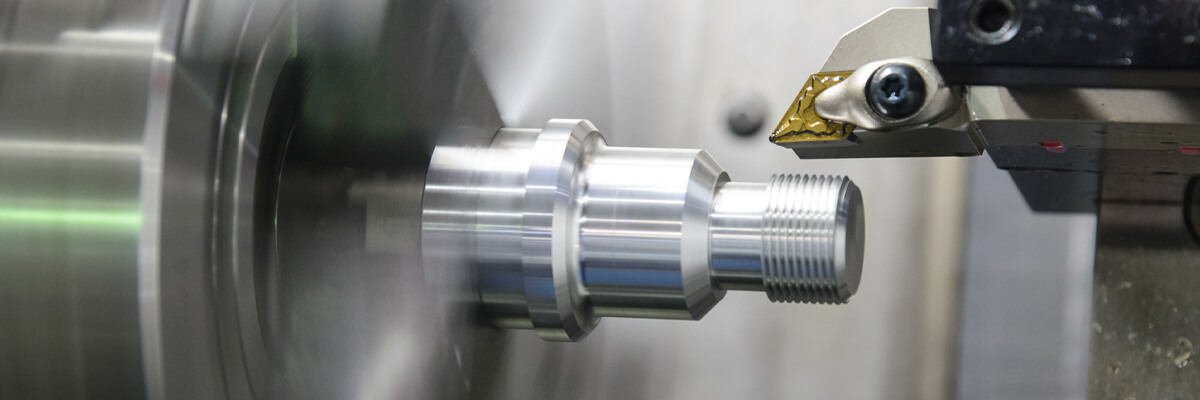

- With CNC turning a metal bar is fed into the lathe and rotates at speed while a single-point cutting tool removes portions of the metal to create the desired shape.

- With milling, the metal usually remains still while multi-point cutting tools rotate around it.

Applications of OEM CNC Turning

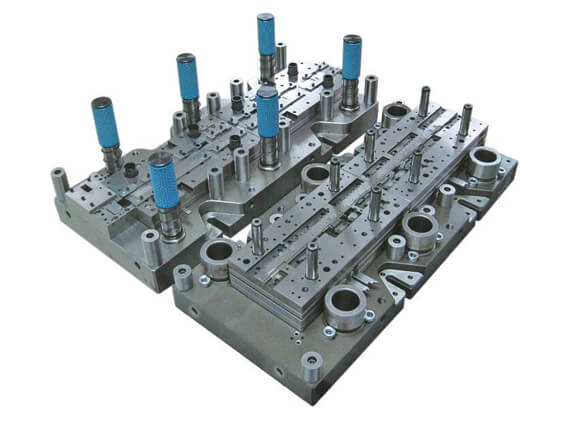

È ampiamente usato nel taglio; lavorazioni complesse; sbavatura; perforazione; centri di lavoro verticali per foratura, alesatura, maschiatura e rettifica; stampaggio ad iniezione elettrica; macinazione; taglio laser; fresatura con centri di lavoro verticali; fresatura; controllo del movimento; svolta; elettroerosione a filo, ecc.

| Lavorazione CNC o no | Lavorazione CNC |

| Materiale | Aluminum, brass, steel, plastic |

| Processi | CNC Macining |

| Capacità materiali | Alluminio, ottone, bronzo, rame, metalli temprati, metalli preziosi, acciaio inossidabile, leghe di acciaio |

| Tolleranza | +/- 0.002 ~ 0.5mm, customized |

| Attrezzature | CNC Machining Center, CNC Lathes, CNC Milling Machines, wire cutting, laser cutting, Stamping machines, Assembly lines, Whole set of measurement tools |

| Servizio | Electronic and communication, Aerospace, Optical instrument, Medical and pharmaceutical, Oil, gas and petroleum, Railway, electric tool, car, robot, hydraulic equipment |

| Finitura superficiale | Anodize, Blacken, polishing, plating, sand blasting |

| Formato disegno | JPEG, PDF, DWG, DXF, IGS, STEP, CAD or according to your sample |

| Inspection | 100% inspection before shipping |

| Certificato | ISO9001 |

| Pacchetto | Sacchetti di plastica e cartone; Esigenza del cliente |

Vantaggi di dipendere da Essai

1. La pressofusione di prodotti in alluminio è offerta a prezzi competitivi.

2. Siamo specializzati in componenti di piccole leghe metalliche da oltre 14 decenni.

3. Impieghiamo i migliori professionisti e le moderne tecniche per la produzione di leghe di alluminio e altri prodotti.

4. Offriamo servizi in diversi settori come hardware, informatica, sanità e automobilistico.

5. I nostri prodotti sono garantiti per darvi una buona reputazione e ci atteniamo a standard di qualità elevati.

6. Eseguiamo test approfonditi dei prodotti.

7. Più di una soluzione è possibile nella nostra organizzazione.

8. Le vostre idee e il vostro design riceveranno una nuova definizione dai nostri esperti.

- +/- 0.0003" tolerance: Typical tolerance, but can vary due to size & type of material.

- Live tooling: Performs up to 12 different CNC milling operations while in the lathe.

- 25" dia x 80" work envelope: Suitable for long or large CNC turning parts and projects.

- Y-axis milling operations: Expands the range of secondary operations, including simultaneous 5-axis milling/turning.

- All metals/alloys: Turn or machine all metals and certain types of plastics.

- Multiple spindle: Turn/mill a complete part in one setup, while maintaining feature relationships.

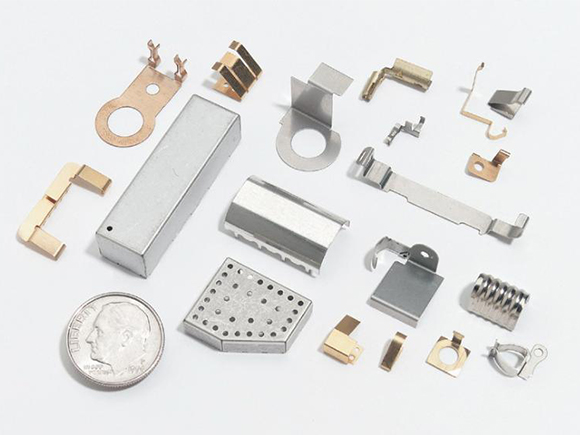

CASO SIMILE

Fornire supporto tecnico hardware per aziende in vari settori.

Non ne sai abbastanza?

Non esitare a contattarci e inizia subito la tua attività!

Ufficio : No.72-6, Huanguan South Road, Longhua New District Shenzhen, 518110 Cina

Fabbrica : No.333 Xiangmang West Road Qingxi Town, Dongguang, Cina