Pengilang Penyemperitan Plastik: Pengenalan Penyemperitan Plastik

2020-06-11Pengeluar Penyemperitan Plastik: Panduan Asas Penyemperitan Plastik

Sebagai pengeluar penyemperitan plastik, kita sering menemui soalan seperti apa penyemperitan plastik? Adakah ia berguna? Adakah terdapat subkategori? Kami faham konsep ini mungkin asing bagi orang di luar industri.

Bagaimanapun, ia melibatkan beberapa teknikal. Oleh itu, menjadikannya terlarang bagi orang yang tidak mempunyai selera dengannya. Walaupun begitu, mempunyai pengetahuan umum tidak pernah buruk. Jadi, hari ini, dalam catatan blog kita akan memberi tumpuan kepada asas penyemperitan plastik.

By the end of the blog, you would be familiar with its basic idea, types as well as its advantages. So, without any further delay, we should get started!

Introduction to Plastic Extrusion

For starters, you need to know what plastic extrusion is. In the technical world, people define this concept as the transformation of solid plastic mass into usable products. The manufacturer would take the plastic mass and turn it into the desired shape.

It is possible to either use these shapes to create additional products, or you can use them as end-products. It all depends upon your requirement. We hope, you now get the basic idea regarding plastic extrusion.

Now, let's dig a little deeper.

Terdapat tiga bahagian plastik yang menghasilkan proses yang merangkumi penyemperitan plastik. Proses-proses ini merangkumi pengacuan tiupan, pengacuan suntikan, dan penyemperitan. Setiap proses adalah penting dan berbeza dengan caranya sendiri.

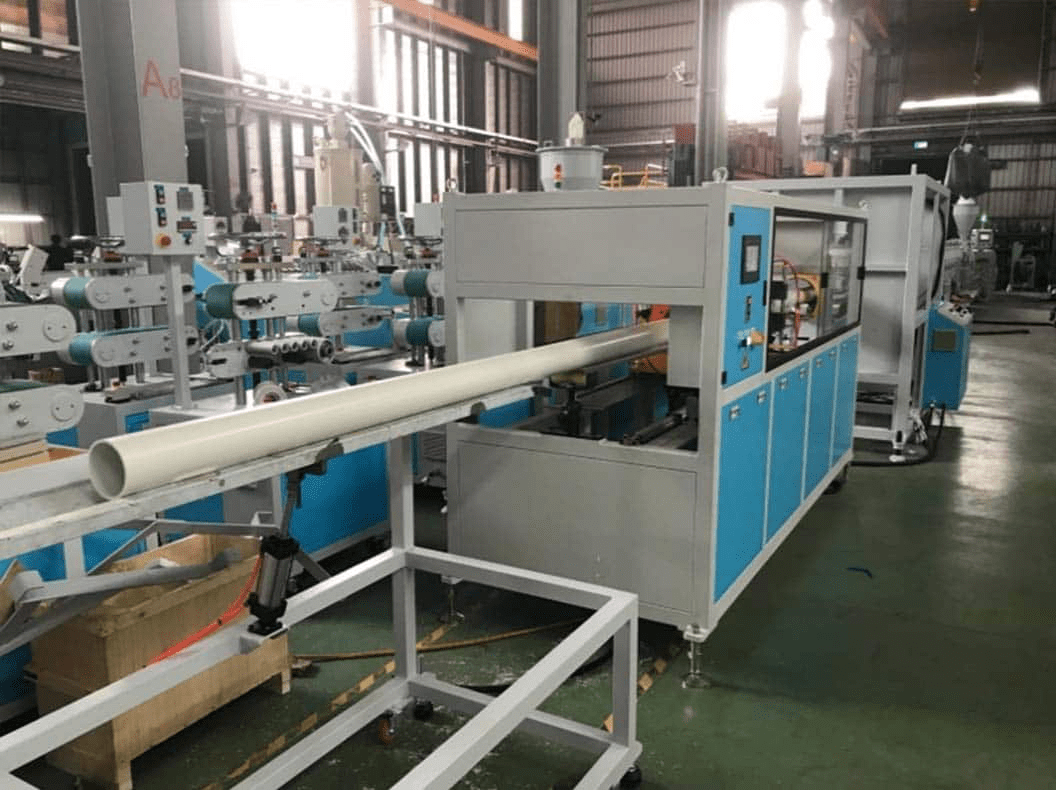

Penyemperitan

Ia adalah proses berterusan. Sesuatu, yang kekurangan proses lain. Semasa penyemperitan, anda akan terus menukar pelet, jisim plastik padat, atau serbuk menjadi bentuk cair. Anda juga akan mendorong bentuk cair ke bentuk menggunakan die.

Bentuknya adalah yang anda mahukan plastik akhirnya. Walau bagaimanapun, ia bukan bahagian akhir. Bentuk ini melalui beberapa proses lain untuk mencapai hasil masing-masing. Sebilangan operasi ini merangkumi paip, profil, filem cor, ditiup, lembaran, atau pelet.

Di bawah ini, kami telah menyenaraikan hasil dari proses ini.

You can turn plastic sheets into either food storage containers or drinking cups.

Plastic pipes that help in delivering water safely to your phone. You do not have to worry about lead contamination. In addition, these pipes do not clad the sides of your house, giving it a less pleasing overview.

For grocery bags, you would be using films. They not only increase the shelf life of the product but at the same time protect it from any sort of harmful contamination.

Every sub-process is different and one of a kind. It requires different downstream equipment, post extrusion, or dies in order to manufacturer the respective product. No matter, what type of process you use, all sub-processes do have one common component, the extruder.

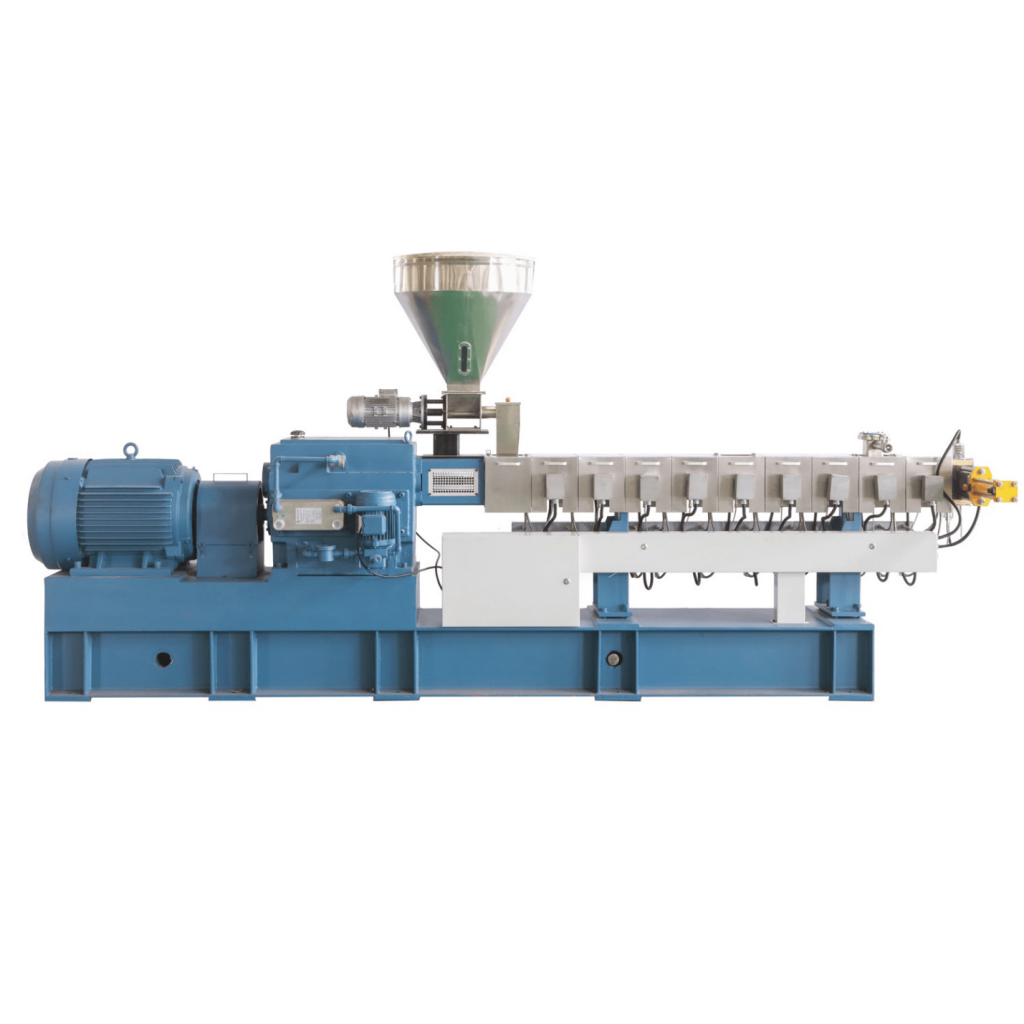

The job of an Extruder

The main job of the extruder to turn the food stock or the solid plastic mass into a melted form. For this purpose, the plastic extrusion manufacturer tends to rely on two different extruding technologies. They can either go with the twin-screw technology or the single screw technology.

Single Screw Technology

Plastic extruding manufacturers around the globe prefer the single screw technology over the twin-screw one. It is most common in the industry. The great thing about this technology is that you can apply is to a wide range of polymer types.

In addition, the technology is applicable to almost all common extrusion processes.

Twin Screw Extruder Technology

On the other hand, we have the twin-screw extruder technology. This is a more sophisticated form of technology. The manufacturers further break down the technology into two parts, the co-rotating, and the counter-rotating technologies.

With the counter-rotating extruder incorporate 2 screws. These screws rotate in opposite direction to each other and they intermesh as well. The co-rotating twin screws also use 2 screws. However, these screws rotate in the same direction and they intermesh as well.

Regardless of the type of technology you use, single or twin, their main objective is the same. They want to turn a solid mass plastic into a melt. Both of these technologies use slightly different mechanisms to serve the same purpose.

Note: The beginning of the intrusion process is the transformation process. Therefore, you need to be extremely careful as it does have a great impact on the entire process.

To highlight its importance, manufacturers call extruder as the heat of the extrusion process. Likewise, they label the extruder screw as the heat of the extruder. After all, the lack of extruder screw performance would have an adverse impact on the entire extrusion process.

The screw needs to perform at the optimal level in order for the extrusion to become a great success.

Plastic Extrusion Manufacturer Categories Extrusion as below

Film/Sheet Extrusion

This particular extrusion process uses a flat die to extrude the molten plastic material. In order to find the sheet or the film’s thickness, the process uses cooling rolls. These rolls are also helpful for determining the texture of the material’s surface.

It is possible to attain the sheet thickness between 0.2 to 15 mm. However, the thickness does depend upon your product or component requirement. It is possible to make a thin flat film or sheet. For effective results, plastic extrusion manufacturer recommends using polystyrene plastic as raw material.

Blown Film Extrusion

Proses ini juga menggunakan die, namun, bukannya rata die seperti silinder menegak. Ia juga dilengkapi dengan profil bulat. Sepasang penggelek puting akan menarik plastik cair dari cetakan ke arah atas. Untuk mengembung tiub, anda akan menggunakan udara termampat.

Lebih-lebih lagi, terdapat cincin udara yang dipasang di sekitar die. Sebab cincin udara adalah menyejukkan filem ketika bergerak ke atas. Untuk memaksa udara termampat ke tengah profil bulat, anda akan melihat masuknya udara.

Saluran masuk udara ini membantu mewujudkan gelembung. Adalah mungkin untuk meningkatkan keratan rentas sekitar dua hingga tiga kali diameter mati. Untuk meruntuhkan gelembung, anda memerlukan plat yang runtuh. Kemudian, lapisan layang-layang bertindak untuk merapikan gelembung menjadi filem lapisan ganda.

Lebih dari Penyemperitan Jaket

Another name for over jacketing extrusion is the wire coating process. From the center of the die, you will be pulling a bare wire. For coating over the wire, you can either use the jacketing or pressure tooling.

These two processes are different; however, they serve the same purpose. Nonetheless, we do recommend jacketing tooling if you require adhesion or intimate contact between coating and wire. In case of pressure tooling, you would retract the wire into the die.

It would then come in contact with the molten plastic. Do remember, that there needs to be a high pressure while the wire is coming in contact with molten plastic. On the other hand, for jacketing tooling, the die comes first, and then the molten plastic would cover the wire after it tends to extend.

You would be feeding the bare wire using the die. It would not come in contact with the molten plastic until it is within the die. The major difference between these processes is that wire positioning with respect to the die.

Plastic Extrusion: Advantages

If there are two or more machines available to feed the single die, it is possible to have co-extrusion. This is highly effective if the product requires multiple layers of different materials.

With co-extrusion, you can add a top layer of high-end material to give the product an expensive look, while using low-cost material underneath to save the overall product cost.

It is a cheaper plastic manufacturing technique. It is possible to improve product durability, properties, fire resistance, static, etc. using different additives.

With plastic extrusion, it is possible to achieve complex shapes with different textures, thickness, colors, etc. You can have access to numerous different shapes and colors, all because of the state-of-the-art technology.

The process is highly effective for producing shapes continuously.