Proses penggilingan dan pengelasan: Melepaskan Jahitan Kimpalan | 2020

2020-06-11Proses mengisar dan mengimpal: Cara Melepaskan Jahitan Kimpalan

Kedua-dua proses penggilingan dan pengelasan kepingan keluli logam perlu dilakukan dengan berhati-hati. Bagaimanapun, proses ini akan memberi kesan langsung kepada kualiti komponen atau produk. Selepas mengimpal produk anda, anda harus memberikan kemasan yang lancar.

Sekiranya anda mencari kaedah untuk menyelesaikan produk anda. Anda telah sampai ke tempat yang betul. Dalam artikel ini, kami akan memberi anda maklumat mengenai cara melepaskan dan menyelesaikan jahitan kimpalan anda.

Panduan Proses Mengisar dan Mengimpal

Before you start with welding, you need to focus on a couple of factors. For starters, you need to understand that every process required different types of finishes. The type mainly depends upon the material and their innate finishing requirements.

For instance, carbon steel would require a different type of finishing in comparison to stainless steel. In this article, we are going to be focusing on these two materials. So, without any further delay, let us get started!

Different Types of Welds

Of course, it is important to learn about different welding types. Below, we are going to focus on these weld types for both carbons as well as stainless steel.

Carbon Steel

Metal Inert Gas Welding

If you are looking for a low-cost welding process for carbon steel, we suggest the metal inert gas welding. People often call this method as Gas Metal Arc Welding process. Despite being cost-effective, it is possible to use the technique on almost all common alloys and metals.

It is popular because it yields outstanding results. For the filling material, the technique uses a semi-automatic wire feed and the inert shielding gas. Industries around the globe consider MIG welding is the best option for thick and heavy items.

However, it tends to produce a fat weld seam. Due to these properties, MIG welding is effective for carbon steel. So, a good idea is to discuss it with your manufacturer, and they will guide you in a proper way.

Stainless Steel

For stainless steel, you would be using the Tungsten Inert Gas (TIG) welding process. TIG is more precise in comparison to some other welding processes. It makes use of a tungsten electrode for the welding purpose.

In addition, you will not find a lot of TIG expertise in the industry. It is a fairly difficult skill set to master. But, that does not mean there aren’t any out there. You just need to reach out to a reliable manufacturer and you will find the TIG expertise.

The process also takes more time in comparison to metal inert gas welding. However, it offers better and finer results. Due to these advantages, the stainless industry is prone to using TIG instead of any other welding process.

Finishing Differences

Selain memfokuskan pada proses penggilingan dan pengelasan, anda juga perlu memberi tumpuan pada penamat bahan. Seperti proses pengelasan , keluli tahan karat dan keluli karbon mempunyai kaedah penamat yang berbeza. Dalam

Lihat di bawah untuk mengetahui perbezaan antara kemasan keluli tahan karat dan keluli karbon.

Kemasan Keluli Karbon

Aplikasi bahagian siap mempunyai kesan langsung pada jenis kemasan yang anda pilih. Bagaimanapun, anda mesti mempunyai tujuan yang jelas tentang apa yang anda rancangkan untuk mencapai kejayaan ini pada penghujung hari. Juga, tidak semua jenis kemasan serasi dengan setiap bahan asas.

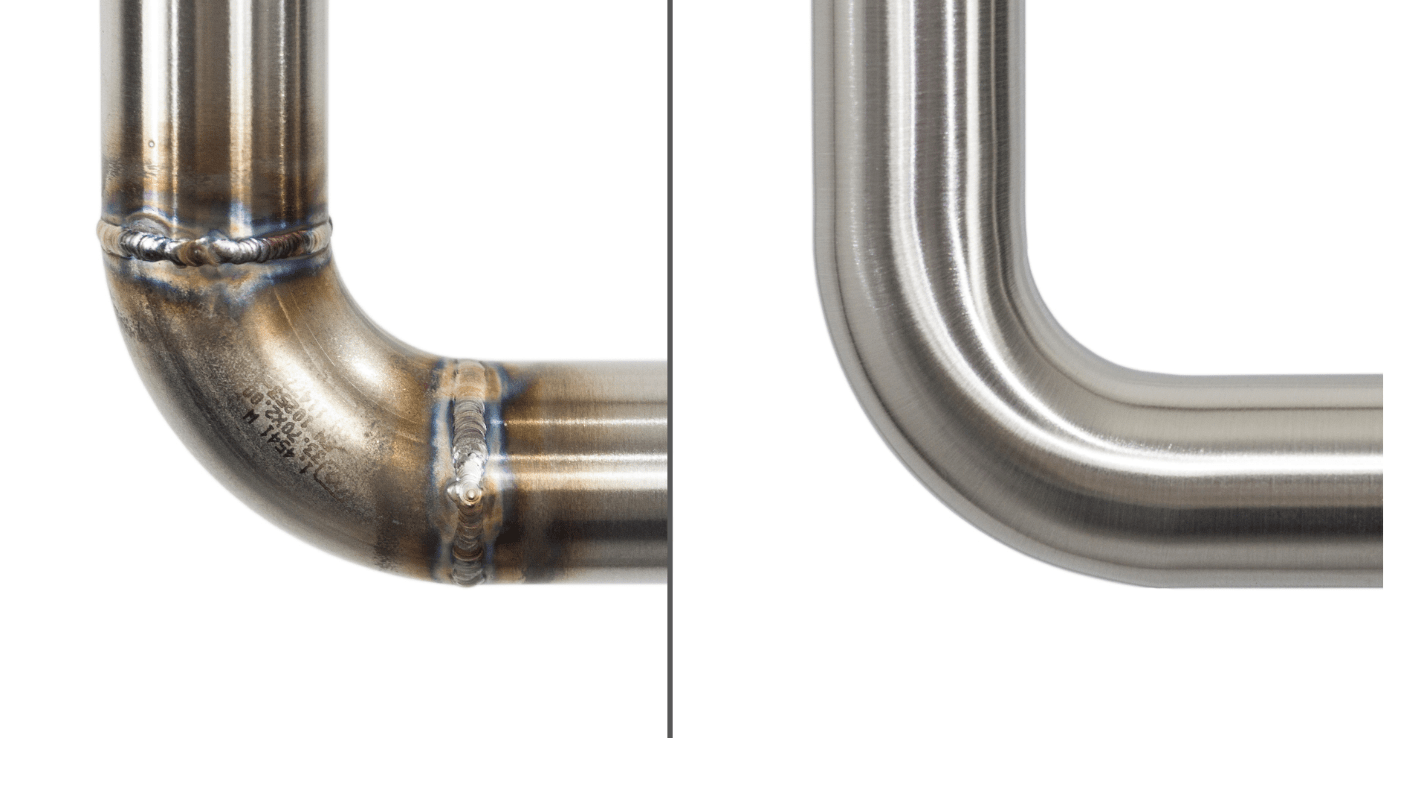

Therefore, you need to focus on the base material as well before finalizing the finish of your product or components. We will be talking about removing the weld seams, but the important thing to understand here is not that you do not have to remove all the welds seams.

There are certain weld seams that are important for the metal’s functionality. Keeping these weld seams would help the metal function more seamlessly and in a better manner. This holds true for most carbon steel applications as the seam would be invisible in most cases.

For instance, undersea applications. Even for the projects that would not be hidden from the human eye. In these cases, it is better to have unfinished welds. After all, these unfinished welds offer more strength in comparison to the finished ones.

The reason being, for finished welds, you actually have to remove a certain amount of material because of the grinding process. When it comes to finishing weld for a carbon steel process, you will be surprised by its simplicity.

You would not have to prepare the entire part or component. On the contrary, you would just have to focus on places where you plan to apply the paint. Moreover, if you want the paint to last long, we recommend having a well-scratched and rough surface.

Experience shows that well scratched and rough surfaces adhere to paint better especially when you want them to have a highly finished shine.

Stainless Steel Finishes

By now, you must know that stainless steel is stronger in comparison to carbon steel. In addition, stainless has a thinner gage in case of usage. Something modern electronics require. After all, these appliances are becoming compact day-by-day.

Stainless steel works well with commercial applications. In addition, its welding finishes have a multitude for these applications. Therefore, it is recommended to use stainless steel for modern, compact, commercial, and sophisticated applications.

For example, to add an aesthetic sense to the application, you can enjoy a highly-refined finish.

Note: In case, you are working with both materials. It is important to keep them separate especially in the finishing section. This would ensure that there is no cross-contamination when you are going from stainless steel to copper.

Proses Pengelasan dan Kimpalan Permulaan

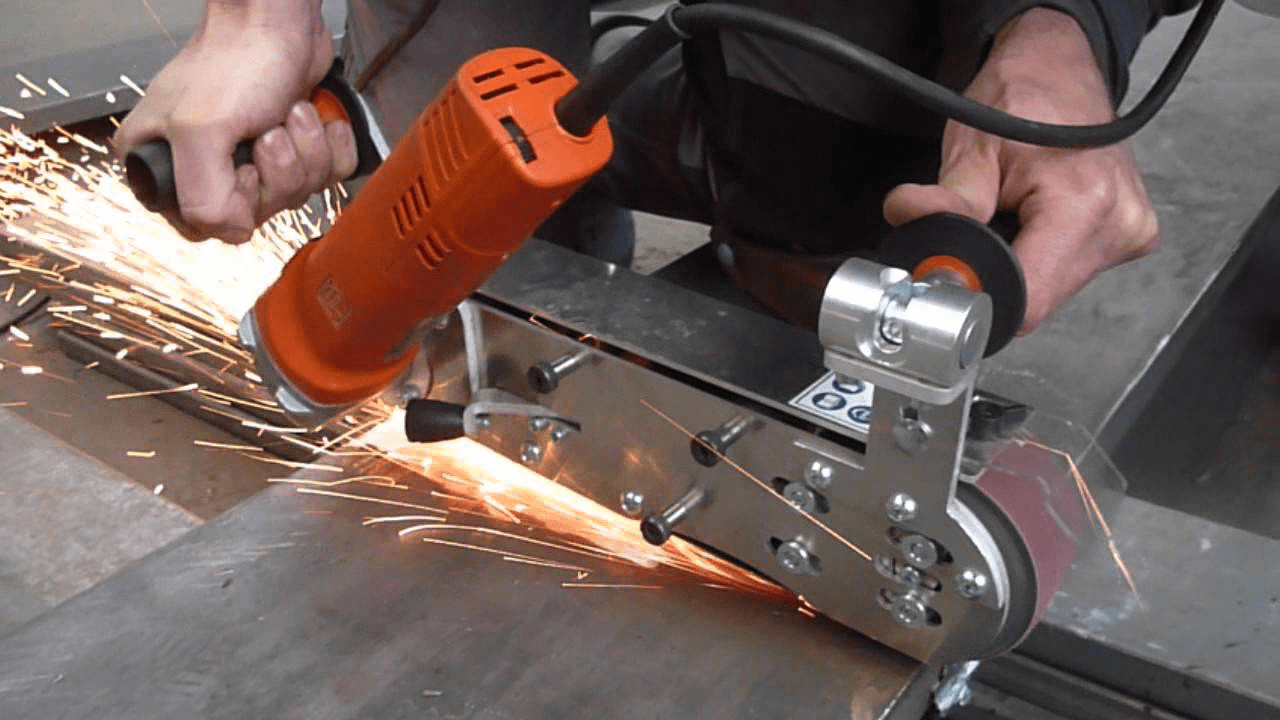

Proses penggilingan dan kimpalan awal biasanya sama. Objektif membersihkan kimpalan dari semua stok berlebihan. Anda mesti mengisar sendi ke tahap tertentu. Selepas itu, anda akan bekerjasama dengan logam induk yang tinggal.

Sekiranya menyelesaikan bukan tujuan anda, maka anda boleh membuang stok awal menggunakan roda penggiling sederhana. Walau bagaimanapun, pastikan roda anda mempunyai penggiling sudut.

Roda pengisar

Adalah mungkin untuk menggunakan roda pengisaran untuk mengeluarkan stok dari kedua bahan. Namun, ingatlah bahawa dalam hal keluli tahan karat, anda perlu mempunyai pekerja yang berkemahiran tinggi bahkan untuk mencapai hasil kualiti yang lumayan.

On the other hand, with carbon steel, you can achieve the desired results with little effort while using the grinding wheel. Just make sure that you adopt the right angel during grinding. After all, you do not want to experience pitfalls such as undercutting or gouging.

Flap Disc on Weld

For effective weld finishing, we recommend using a flap disc. They show impressive results for both carbon steel as well as stainless steel. Since they ensure long product life, therefore, they have an edge over their counterpart, standard grinding wheel.

In addition, flap disc offers superior operating control as well as comfort. They generate less noise and the quality of surface finish that they offer is outstanding. For carbon steel, you would save give and have effective results if you use the P40 coarse grit.

Bawa pulang

A great manufacturer would always focus on the grind and welding process. After all, the manufacturer does understand its importance in terms of product life and finish. There are certain elements that contribute to deciding the right welding and grinding process.

For instance, the type of material you are planning to use, and product finish that you require among others. Like a lame man or a non-professional, you might not have the required knowledge to make this decision.

So, what are you to do? Simple, you need to reach out to consumers to us and we will answer all your queries in an effective manner. We will help you choose the right process to ensure great results. After all, it is our aim to please ours in every possible way.