Iată ce ar trebui să faceți pentru SUDAREA FRICTION STIR WELDING (FSW)?

23.07.2020SUDARE CU FRAGĂ: INOVATOR ȘI CU EMISII SCĂZUTE

Introducere în Sudare prin frecare (FSW) technology

Tehnologia inovatoare de Sudare prin frecare (FSW) a fost optimizată continuu timp de două decenii. Nu numai că oferă avantaje tehnologice, dar se caracterizează și printr-un nivel de emisii deosebit de scăzut. Acest lucru beneficiază atât utilizatorii, cât și mediul.

With thermal welding processes, the work piece must be melted on the joining zone. In addition to possible problems, changes in material properties and reduced stability also occur. Pollutants are also separated in conventional welding processes.

In thermal welding, an arc or gas flame creates a weld pool. And the weld fumes emitted by the weld pools are in some cases extremely harmful to health. Similarly, it brings impact on the climate and the environment.

What is Friction Stir Welding (FSW) ?

Sudare prin frecare (FSW), however, always works at temperatures below the melting point. This means that there is no melt pool and air-tight protective gases can be completely dispensed with. Friction stir welding thereby reduces emissions that are harmful to health, the environment and the climate.

Datorită eficienței sale ridicate și metodei de lucru minim invazive, sudarea prin frecare prin amestecare (FSW) permite 2chiar și în producții standardizate, reproductibile pe scară largă.

Motivul pentru aceasta constă în tehnologia extrem de specializată care funcționează fără utilizarea de materiale suplimentare.

Cum funcționează ?

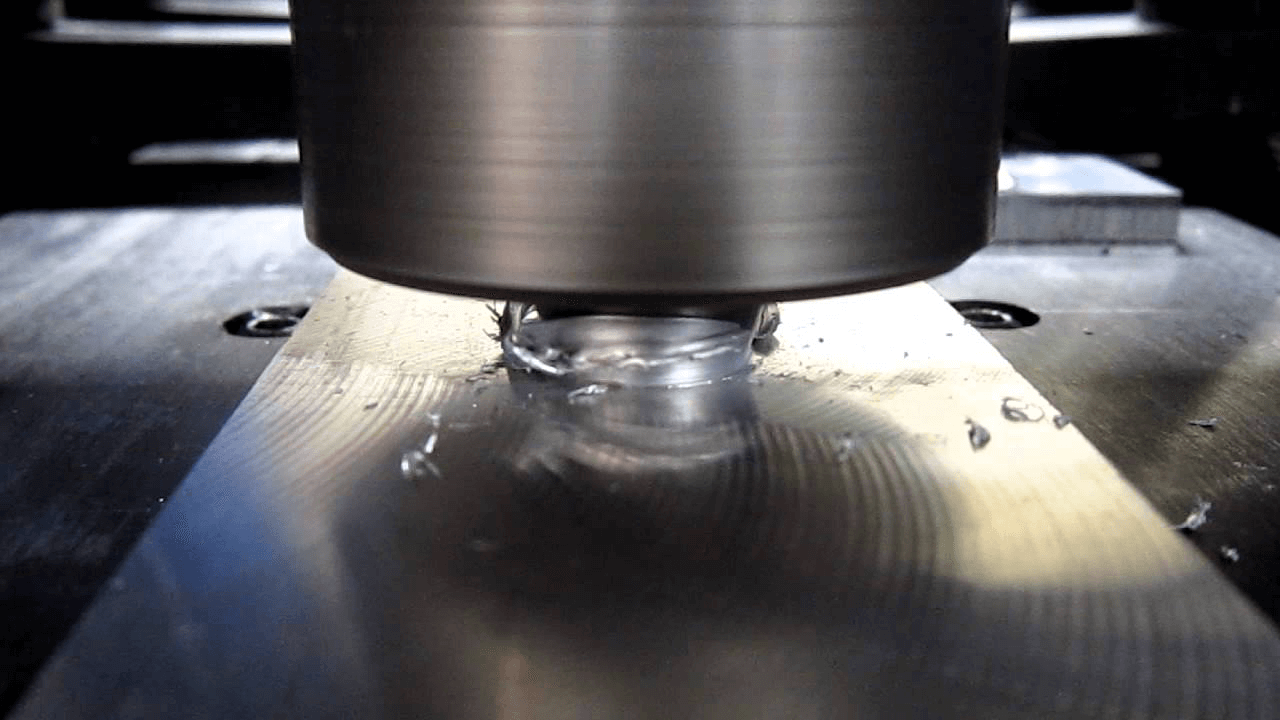

Piesele de lucru sunt mai întâi încălzite la golul articulației numai de energia de frecare a sculei până la punctul de topire.

Acest instrument amestecă apoi materialul plastifiat al partenerilor de îmbinare într-o cusătură de înaltă rezistență, neporoasă și chiar etanșă la gaz.

sudarea prin frecare prin amestecare (FSW)is also characterized by a positive energy and resource balance. In addition to the absence of shielding gas or welding gas, no additional filler materials are required.

For instance, wire with which the joint gap is filled during thermal welding. The energy applied is used without loss and immediately in the production of weld seams. Friction stir welding therefore has a very high efficiency and high energy efficiency among the joining processes.

The method of Friction Stir Welding (FSW) is particularly suitable for light metals. Such as:

- aluminum and

- alloys

Many producers of parts for the mobility industry use these light metals. This helps to reduce the weight and energy consumption of ships, vehicles and airplanes.

This aspect is particularly important in the planning and construction of technologies in e-mobility. For reasons of efficiency, the energy source must be of the lowest possible mass. But this reduces the range of the vehicles.

In order to ensure their full performance, frequent, short reloading at the final stops is necessary. The heat generated in the batteries must be dissipated via cooling plates.

By connecting the individual components using Sudare prin frecare prin amestecare a product has now been realized that optimally fulfills the cooling performance requirements. And at the same time, it reduces the weight to a necessary minimum.

In this way, an environmentally friendly manufacturing process promotes the implementation of future-oriented technology.

sudarea prin frecare prin amestecare (FSW)involves joining metals below the melting point. This creates pressure- and vacuum-tight connections without pores and cracks.

The technology is also known as friction stir welding. partajați has successfully used the economical and environmentally friendly welding process for many years in industries such as:

- Automobile

- Food

- Medical technology

- Aerospace

- mechanical engineering

- transport

Sudare prin frecare (FSW) is always finding new applications

The demands on materials are getting higher and higher. They should be light, stable and easy to work with. Therefore metal alloys are used. They have the advantages of the individual metals. But it reduces their disadvantages to a minimum.

Such components are joined by sudarea prin frecare prin amestecare (FSW)methods. But these processing methods have disadvantages.

Common Friction Stir Welding (FSW) joining techniques

The shortcomings of riveting lie in:

- the higher material consumption and

- the associated higher weight,

- susceptibility of the drilling sites to corrosion and

- Their weakening of material due to the drilling process.

In fact, the process is very time-consuming since each rivet connection has to be checked individually.

Welding liquefies the material and changes its structure. Pore formation, caused by oxidation, further destabilizes them.

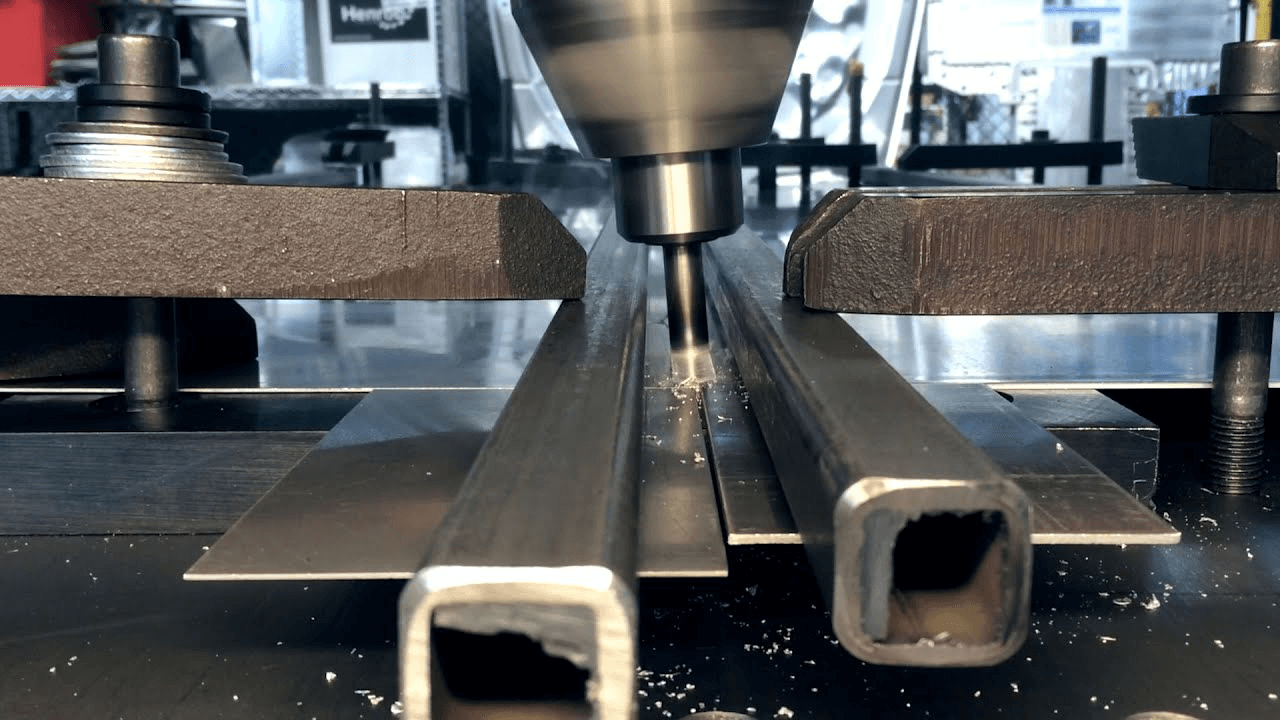

Friction Stir Welding (FSW) working flow

Pentru a depăși aceste dezavantaje, sudarea prin frecare prin frecare (FSW) a fost dezvoltată în Marea Britanie. Sudarea are loc în faza plastică, astfel încât materialul de bază să nu se topească.

Cu o forță mare, un știft rotativ este presat între două foi și mișcat de-a lungul liniei de îmbinare. Datorită fricțiunii, piesele sunt încălzite și agitate astfel încât foile să se unească.

Sudarea are loc sub punctul de topire a materialului. Astfel încât să nu apară modificări structurale dezavantajoase atunci când topitura se solidifică. Aceasta înseamnă că chiar și aliajele de aluminiu greu de sudat pot fi sudate.

Cu toate acestea: deși procesul este aplicabil tuturor metalelor, este utilizat în principal pentru metalele cu un punct de topire scăzut datorită uzurii ridicate a sculei.

Nevertheless, the advantages outweigh. By handling the workpieces gently, the users achieve high static and dynamic seam strength.

And at the low temperatures there is no more smoke and nothing splashes. In fact, the energy consumption is also low, the work piece is warped only slightly and the entire process can be easily automated. The post-treatment of the weld seam, as it is necessary with Friction Stir Welding techniques.

Friction Stir Welding (FSW) working precautions

However, this process requires careful work. The materials must be clamped and aligned precisely since their position cannot be changed during the welding process.

Here, the material is exposed to heavy loads due to clamping. A back support is also required. It must consist of a material that has a higher melting point than the material to be processed.

At the end of the welding process, the rotating pin makes a notch in the material. It can lead to a crack if cyclically loaded.

To prevent this, another piece of metal is simply placed behind the material. So that the pin welds a little further than the workpiece is long.

However, further questions are still open. How can lap joints be welded efficiently? The question of welding metals with extremely different melting points has not yet been sufficiently clarified.

Concluzie

Alloys made of aluminum and magnesium, titanium or steel are particularly in demand here. Because the demands on modern materials are getting higher and higher.

sudarea prin frecare prin amestecare (FSW) este potrivită în special pentru îmbinarea economică a metalelor neferoase cu o temperatură de topire scăzută și conexiuni mixte. Chiar și materiale străine greu de sudat sau, cum ar fi:

- Aluminiu

- Magneziu

- Cupru

- Titanul poate fi îmbinat