OEM Aluminum Die Casting Part Manufacturer

- High operating temperatures

- Outstanding corrosion resistance

- Very good strength and hardness

- Excellent thermal conductivity

- Good stiffness and strength-to-weight ratio

When you need aluminium die casting parts processed with high precision, please ask us for help. Essai offers you high quality aluminum die-cast parts and components in a variety of industries.

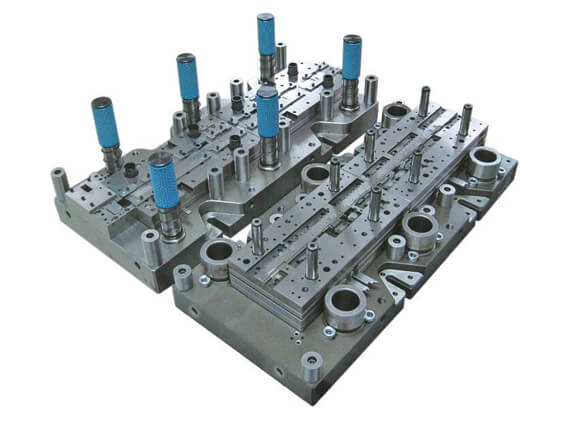

OEM Aluminum Casting is a manufacturing process for producing accurately dimensioned, sharply defined, smooth or textured-surface aluminum parts through the use of reusable molds, called dies. The aluminum dies casting process involves the use of a furnace, aluminum alloy, die casting machine, and die. Dies that usually constructed with long-lasting, quality steel have at least two sections to permit removal of castings.

Advantages of OEM Aluminum Casting

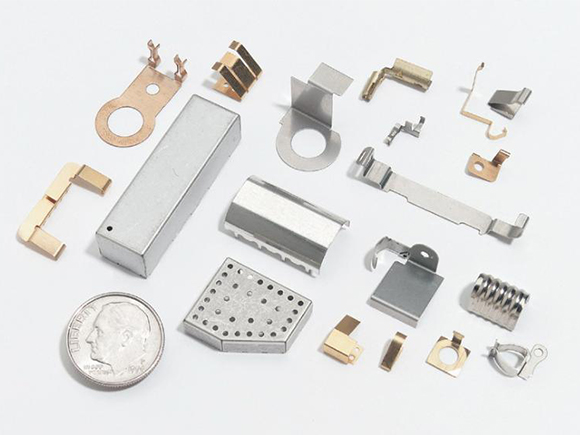

One of the most significant benefits of aluminum die casting is that it creates lighter parts—with more surface finishing options than other die cast alloys. Aluminum can also withstand the highest operating temperatures of all the die cast alloys. Moreover, cast aluminum is versatile, corrosion-resistant; it retains high dimensional stability with thin walls and can be used in almost any industry.

OEM Aluminum Casting Applications

- They improve automotive fuel efficiency by contributing to weight saving requirements.

- Aluminum is used in a broad range of networking and infrastructure equipment in the telecom and computing industries because RF filter boxes and housings require heat dissipation.

- In handheld devices, aluminum castings provide EMI/RFI shielding, rigidity, and durability with minimal weight.

- Because of aluminum’s excellent electrical performance and shielding properties, even in high-temperature environments, die cast aluminum is ideal for electronic connectors and housings.

| Material | ADC12 / A380 / A360 / LM6 |

| Cavity | 1 Cavity |

| Mould life | 50000 Shots |

| Mould Material | H13 Heat Hard |

| Tolerance | +/-0.01mm |

| Mould Base | Standard |

| Surface Treatment | Polishing + powder coating |

| Certification | ISO9001: 2008 |

| Package | Plastic bags & carton; Customer's requirement |

Advantages of depending on Essai

1. Die casting of aluminium products is offered at competitive prices.

2. We specialize in small metal alloy components for more than 14 decades now.

3. We employ the best professionals and modern techniques for making aluminium casting alloys and other products.

4. We offer services in diverse industries like hardware, computing, healthcare and automotive.

5. Our products are guaranteed to give you a good reputation and we stick to high standards of quality.

6. We do extensive testing of the products.

7. More than one solution is possible in our organization.

8. Your ideas and design will be given a new definition by our experts.

- High operating temperatures

- Outstanding corrosion resistance

- Lightweight

- Very good strength and hardness

- Good stiffness and strength-to-weight ratio

- Excellent EMI and RFI shielding properties

- Excellent thermal conductivity

- High electrical conductivity

- Good finishing characteristics

- Full recyclability

SIMILAR CASE

Provide technical hardware support for enterprises in various industries.

Don't know enough?

Welcome to contact us And Start Your Business Now!

Office: No.72-6, huanguan South Road,Longhua New District Shenzhen, 518110 China

Factory: No.333 Xiangmang West Road Qingxi Town,Dongguang ,China