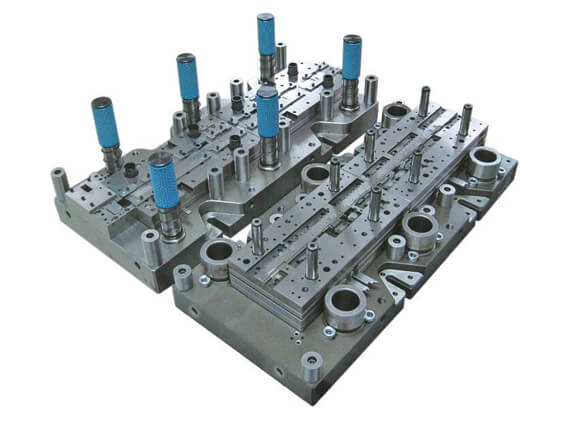

Die Casting Mold

Die-casting mold is important to process equipment in die-casting production. It plays a very important role in whether the production can be carried out smoothly and the quality of the castings. It has an interaction and a restrictive relationship with the die-casting production process and production operation.

1. Its important functions are:

- Determines the casting shape and size tolerance level.

- The pouring system determines the filling status of the molten metal.

- Control and adjust the thermal balance of the die-casting process.

- The strength of the mold limits the maximum value of the injection specific pressure.

- Affects the production efficiency of die-casting production.

2. Die-casting mold structure

The following introduces the structure of the die-casting mold, analyzes the role of each component in the mold, has a preliminary understanding and understanding of the basic structural form, fixing method, selection of materials and heat treatment of the mold. It is mainly composed of a fixed mold and a moving mold. The fixed mold and the injection part of the machine are connected and fixed on the head plate. The moving mold is installed on the middle plate of the die casting machine and the Move and close or separate from the fixed mold.