Processamento de casca de metal: tipo e características de fabricação

2020-09-19Processamento de casca de metal: tipo e características de fabricação

Questões envolvidas no material:

- Sobre os materiais usados para fazer o invólucro de metal

- Tipo de casca de chapa de metal

- Tecnologia de fabricação de casca de chapa metálica

- Com relação à ergonomia e resfriamento de gabinetes de chapa de metal

O processamento de casca de metal é usado para fazer computadores modernos ou, mais precisamente, unidades de sistema. Cada unidade do sistema contém um grande número de elementos, que são responsáveis pelo funcionamento de todo o PC. Isso inclui unidades de fonte de alimentação, placas-mãe, unidades ópticas, discos rígidos, etc.

Existem muitos tipos de caixas de chapa, que são fabricadas de acordo com a sua tecnologia. Além disso, é importante proporcionar refrigeração e ergonomia ao equipamento. O tipo de metal feito na caixa desempenha um papel importante. Geralmente, existem muitas nuances no processo de fabricação de equipamentos de informática. Se quiser que seu computador funcione normalmente por um longo tempo, você deve entendê-los.

Materiais usados para fazer invólucros de metal

Na fabricação de invólucros metálicos para tecnologia de informática, são necessários materiais com determinadas características, o que dificulta a escolha. Eles devem fornecer a proteção necessária para os componentes do computador contra vibração e quaisquer influências mecânicas. Ao mesmo tempo, devem contribuir para o rápido resfriamento dos componentes geradores de calor durante a operação do equipamento. Portanto, o alumínio é geralmente selecionado para a fabricação de caixas de alta qualidade,

O motivo está nas características do metal. Ele tem a melhor dissipação de calor e capacidade de dissipação de calor. O cobre tem a mesma qualidade, mas o alumínio é mais leve e barato. No entanto, os invólucros metálicos de placas feitas de SECC (aço especial) revestidos com soluções de eletrogalvanização têm sido mais amplamente utilizados. Eles são usados no segmento de preço médio da tecnologia de informática.

Recently, aluminum has become the most commonly used housing material due to its value. The structural properties of aluminum and its appearance provide designers with huge opportunities

Tipo de casca de chapa de metal

Mass production requires strict manufacturing standards for various types of products. This applies to almost all industrial fields, and computer technology manufacturing is no exception. Compliance with the standard not only allows you to be confident in the strict parameters of the components used, but also allows you to assemble equipment from components designed and produced by a large number of suppliers.

The conditions for further use constitute the standard size of the product. For ease of use, the housing has certain characteristics. There is still no perfect standard. 25 standard sizes are now used. These are not only metal shells for mass production, but also single shells designed to solve special problems. The latter is specifically needed by narrow experts. Most people's interests extend to the former, and we will consider them in the future.

1. Single piece.

It is a single unit of PC system equipment, monitors, speakers and other components. Except for the system unit, the latter is usually an external device, but not in this case. The size of the product is not standardized and only meets the manufacturer's standards.

Monolith

The most famous is Apple devices. These monolithic "Macs" are still one of the most reliable and beautiful products on the market.

The advantage of this situation is its compactness, that is, the smallest space occupied by the entire device. However, this is also its disadvantage. Such equipment is difficult to upgrade. Due to the lack of space inside the shell, it is impossible to change the packaging, make improvements, and install more powerful components.

This is why the entire house is actually not suitable for family use when the owner does not plan to upgrade. Therefore, they are often used in production. The housing is generally rectangular and made of metal. They are equipped with electronic components, and connection ports and various indications are located on the back and front of the case. They are installed in 19 racks, one above the other. In this case, the rear wall of the upper housing becomes the upper wall of the lower housing. Now, this component has become the main component for installing telecommunications equipment and servers.

See also: Principles of Laser Cutting: Techniques and Equipment Used

The overall block is the designer used to build the computer. In this case, the component is already installed in it. The owner of such a device can simply replace the RAM, processor or hard drive in it. But, for example, it is almost impossible to replace the motherboard. In any case, this will cause serious difficulties.

If the owner plans to change it to a more modern candy in a few years, they can buy a home candy bar because upgrading is difficult. But for organizations, monolithic blocks are convenient because they make it possible to quickly create several computer-equipped workplaces.

2. AT and Slim.

At the end of the last century, at the beginning of the computer era, PC cases were manufactured according to AT standards. Today, this is a thing of the past, and the ATX standard is now used. But on this basis, they created samples for Slim and Ultraslim. These are ultra-thin and ultra-thin shells. Their main purpose is to look stylish. Otherwise, they will not be very convenient because installing serious fillers in them will not work-the space is too small.

AT and Slim

This shell standard is very popular in Western countries, but not in Russia. The space saved by the manufacturer has attracted Western buyers. After all, you can put the computer system components on the table and the monitor on top of it.

Some of the most commonly used types of horizontal metal PC cases are:

Desktop computer (desktop computer) with a size of 533x419x152 mm;

Footprint (floor) 408x406x152 mm;

SlimLine (thin type), the size is 406x406x101 mm;

UltraSlimLine (ultra-thin) 381x352x75 mm.

3. The vertical (tower) metal casing of the notebook computer.

A computer case placed vertically in space is called a "tower" or tower. Experts believe that in this case, in order to quickly cool the PC, the components should be placed as easily as possible.

Vertical (tower) metal computer case

In this case, consumers will find the most convenient option for themselves. It may be the case of modern servers, or only for devices with typewriter capabilities.

Consider the most popular ATX vertical chassis in Russia:

They are also called "full towers". The size in this case is 200x600x1000 mm. There are 5.25" and 3.5" bays inside, the first of which is used to accommodate optical drives (4-9 can be), and the second is for hard drives (6-12). In addition, seven expansion cards can be placed in the tower. This is the sound card, receiver, etc.

In addition to the above, in this case, you can also place an ATX motherboard (standard size) so that you can assemble a server or a high-performance gaming computer. There will be enough space to accommodate various other equipment.

BigTower or "Big Tower". The size in this case is 190x482x820 mm. In addition to full towers, they can also provide full-size ATX motherboards, but there is nowhere to install other equipment. In this case, it can also be used to create a game computer.

These are the most famous and commonly used standard hulls in our country-the "middle tower". Their dimensions are 183x432x490 mm. This kind of case can accommodate power supply equipment, ATX board. RAM (2 slots) and hard drives (several) can be built-in. This is the most versatile case because it can be used to assemble office computers or powerful gaming PCs, or you can make a media center for your own home.

The size of this "tower" is 178x432x432 mm. The chassis is very small and can be assembled into a home computer or home theater. Such a body takes up very little space.

MicroTower is the smallest vertical metal enclosure. The size of this baby is even smaller. It is suitable for low-power devices with motherboards with built-in peripherals.

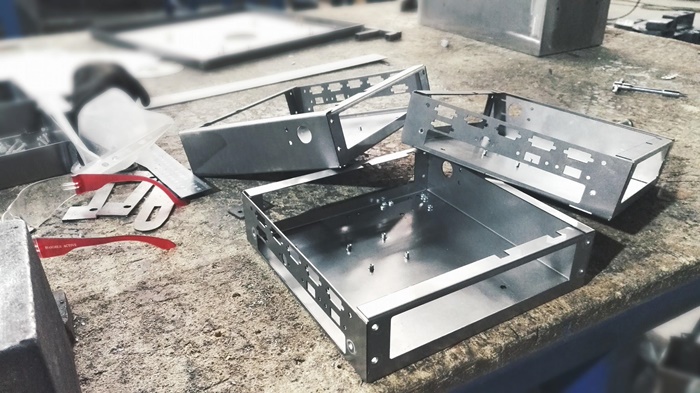

Manufacturing technology of sheet metal shell

Let us consider the various methods used to manufacture metal casings used to manufacture electronic devices.

Cold plate stamping.

The housing of the electronic equipment (CEA) is made by cold stamping sheet metal. Although this method has been used for a long time, it has not lost its relevance. Its essence is to use special stamps. It is used for the production of mass products and the start of mass production. The role of the mold is to form different parts of the body. For small batches and single products, this technique is impractical because of the high cost of manufacturing stamps.

Sheet metal processing.

Moreover, in many cases, the housings of electronic devices are made by sheet metal processing methods. This technology is used for the production of small batches of products. For example, the developer chose a specific metal housing design. Then, he needs to decide how to do it: commission a separate development based on certain requirements or use a ready-made model to make some adjustments for himself.

Escolha o método de fabricação da casca de acordo com o tamanho do lote. Ao planejar um grande número de instrumentos, o projeto individual e o uso de métodos de estampagem a frio na fabricação devem ser considerados. Na produção de pequenos e médios lotes, vale a pena usar soluções prontas. Ao mesmo tempo, o processamento da chapa de metal do material ajudará a fazer as alterações necessárias no design durante o processo de produção, após o que o produto corresponderá totalmente ao equipamento fabricado.

Use máquinas-ferramentas CNC.

A carcaça de equipamentos eletrônicos também pode ser produzida em máquinas CNC (controle numérico computadorizado). Este é um método bastante popular. Com sua ajuda, pequenos lotes de caixas e cópias individuais podem ser feitos. Deve-se notar que o custo desses produtos é muito baixo. Acredita-se que com esta saída, a utilização de equipamentos CNC seja economicamente viável. Essas máquinas são compactas e não requerem uma grande pegada, o que torna os produtos de fabricação baratos.

Além disso, o uso de equipamento CNC pode reduzir o número de especialistas trabalhando para ele. Isso significa que o fator humano na produção é reduzido, de forma que o produto é de alta qualidade, mas os defeitos são realmente eliminados. Essas vantagens tornam possível o uso do dispositivo não apenas na produção de casas em pequena escala, mas também na fabricação de produtos de grande porte.

Ergonomia e resfriamento da caixa de chapa de metal

Anteriormente, mencionamos uma das principais funções de uma caixa de computador - dissipar o calor do elemento de aquecimento da unidade do sistema. O aumento no número de ventiladores não pode evitar o superaquecimento devido ao resfriamento específico dos componentes do PC. Os melhores resultados podem ser alcançados colocando o ventilador corretamente e, assim, organizando o movimento do ar dentro do dispositivo.

There is no need to evaluate the ventilation system installed on the PC by the number of coolers. With their help, heat is dissipated from the heating element. If the cooling system is not installed correctly, the hot air currents will collide with obstacles or each other, making it impossible to cool the equipment.

Below is a photo of a relatively reasonably constructed ventilation scheme for a metal computer case. After careful inspection, you will find one or several low-speed coolers (at the input) installed in the case. They suck cool indoor air into the system unit. A smaller and more powerful fan is placed behind (at the outlet) to blow out the heated air. This circuit allows you to generate thrust. Therefore, the metal body is a cooling turbine, in which cold air enters the heating element, they are cooled, and then the system guides the heated air to the outside.

See also: bent aluminum tube

The proposed solution can also be supplemented with coolers located near the side walls and the top wall. They must blow out the air.

Therefore, in order to create a system that properly cools the metal PC case components, you should remember:

Mais ventiladores não significa melhor dissipação de calor.

O movimento do ar em uma direção deve ser organizado, não dividido em correntes de ar.

Com base no currículo escolar, você pode saber que o ar quente sempre sobe, enquanto o ar frio desce, portanto, você não deve colocar unidades verticais do sistema horizontalmente.

Cabos soltos dentro do dispositivo impedirão a circulação de ar.

Um ventilador com pás grandes e baixa velocidade aumentará o fluxo de ar.

A quantidade de ar que o ventilador pode soprar no chassi em um minuto deve ser considerada com cuidado.

Ergonomia e resfriamento de carcaças de chapa metálica

Este parâmetro é denominado CFM-pés cúbicos por minuto. Deve-se garantir que o ar no recinto circule continuamente. Para calcular qual ventilador pode fornecer essa função, você deve:

Calcule a área da caixa. Para fazer isso, multiplique seu comprimento por sua largura e altura.

Calcule o CFM do refrigerador.

Por exemplo, o volume de uma caixa de 253 x 502 x 563 mm é 2,52 pés cúbicos. O ar na caixa deve ser trocado a cada 2 segundos, portanto, um resfriador de 70 CFM é necessário. Às vezes, você encontrará um PC com aberturas que resfriam o processador na forma de um tubo na lateral do gabinete. Eles trazem poucos benefícios, mas são mais prejudiciais porque criam obstáculos ao fluxo natural do ar. Eles devem ser removidos e fixados na caixa de arame.

Dust filters (such as ducts) also cannot help the fan to cool the components of the computer. Within 2-3 months from the date of installation, they will soon be clogged with indoor dust, so their performance is very low. In addition, the mesh clogged with dust can interfere with the movement of the air, causing the device to overheat. Therefore, the productivity of this equipment is low.

The screws that used to support all PC components have gradually become history. During the computer assembly/disassembly process, a large number of screws are inconvenient to use. Everyone who has analyzed a system analyzer knows this.

This is the reason why manufacturers have long used plastic buttons and "bases" for hard drives to complete computer technology.

In addition, clamps, plugs, additional fasteners, etc. are used, which makes the box more convenient. The ergonomic chassis helps you replace components and upgrade your computer internally and externally.

It is worth paying close attention to the cables located inside the chassis. The efficiency of cooling systems depends on their location. However, we must not forget the convenience of connecting new devices and devices.

Why contact us

We respect all customers and strictly execute tasks of any scale.

Our production facilities enable us to process various materials:

Non-ferrous metals;

cast iron;

stainless steel.

When completing the order, our experts will use all known metal processing methods. The latest generation of modern equipment can conform to the original drawings to the greatest extent.

In order to make the workpiece closer to the sketch proposed by the customer, our experts use universal equipment designed for jewellery polishing tools for particularly complex operations. In our production workshop, metal becomes a malleable material, which can be used to manufacture any workpiece.

The advantage of contacting our experts is that they meet GOST and all technical standards. In each stage of work, strict quality control is carried out, so we guarantee to provide customers with carefully implemented products.

Graças à experiência dos nossos artesãos, o resultado é um produto modelo que atende aos requisitos mais exigentes. Ao mesmo tempo, partimos de uma base material sólida e nos concentramos no desenvolvimento de tecnologias inovadoras.

Cooperamos com clientes em várias regiões. Se você deseja fazer um pedido de processamento de metal, nosso gerente está sempre pronto para ouvir todas as situações. Se necessário, podemos oferecer aos clientes consultoria profissional gratuita.