Verwerking van metaaldoppe: tipe en vervaardigingseienskappe

2020-09-19Verwerking van metaaldoppe: tipe en vervaardigingseienskappe

Kwessies betrokke by die materiaal:

- Oor die materiale wat gebruik word om die metaalomhulsel te vervaardig

- Tipe plaatmetaal dop

- Vervaardigingstegnologie van plaatmetaal

- Wat ergonomie en afkoeling van plaatmetaalbehuise betref

Metaalskaalverwerking word gebruik om moderne rekenaars, of meer presies, stelsel-eenhede te maak. Elke stelseleenheid bevat 'n groot aantal elemente wat verantwoordelik is vir die werking van die hele rekenaar. Dit sluit in kragtoevoereenhede, moederborde, optiese dryf, hardeskywe, ens.

Daar is baie soorte plaatmetaalbokse wat volgens hul tegnologie vervaardig word. Daarbenewens is dit belangrik om afkoeling en ergonomie in die toerusting te bied. Die tipe metaal wat in die koffer vervaardig word, speel 'n belangrike rol. Oor die algemeen is daar baie nuanses in die vervaardiging van rekenaartoerusting. As u wil hê dat u rekenaar lank normaal moet werk, moet u dit verstaan.

Materiale wat gebruik word om metaalomhulsels te maak

In the manufacture of metal casings for computer technology, materials with certain characteristics are required, which makes it difficult to choose. They must provide the required protection for computer components from vibration and any mechanical influences. At the same time, they should contribute to the rapid cooling of heat-generating components during equipment operation. Therefore, aluminum is usually selected for the manufacture of high-grade housings,

The reason lies in the characteristics of the metal. It has the best heat dissipation and heat dissipation capacity. Copper has the same quality, but aluminum is lighter and cheaper. However, the metal shells of plates made of SECC (special steel) coated with electro-galvanizing solutions have been more widely used. They are used in the mid-price segment of computer technology.

Recently, aluminum has become the most commonly used housing material due to its value. The structural properties of aluminum and its appearance provide designers with huge opportunities

Tipe plaatmetaal dop

Mass production requires strict manufacturing standards for various types of products. This applies to almost all industrial fields, and computer technology manufacturing is no exception. Compliance with the standard not only allows you to be confident in the strict parameters of the components used, but also allows you to assemble equipment from components designed and produced by a large number of suppliers.

The conditions for further use constitute the standard size of the product. For ease of use, the housing has certain characteristics. There is still no perfect standard. 25 standard sizes are now used. These are not only metal shells for mass production, but also single shells designed to solve special problems. The latter is specifically needed by narrow experts. Most people's interests extend to the former, and we will consider them in the future.

1. Single piece.

It is a single unit of PC system equipment, monitors, speakers and other components. Except for the system unit, the latter is usually an external device, but not in this case. The size of the product is not standardized and only meets the manufacturer's standards.

Monolith

The most famous is Apple devices. These monolithic "Macs" are still one of the most reliable and beautiful products on the market.

The advantage of this situation is its compactness, that is, the smallest space occupied by the entire device. However, this is also its disadvantage. Such equipment is difficult to upgrade. Due to the lack of space inside the shell, it is impossible to change the packaging, make improvements, and install more powerful components.

This is why the entire house is actually not suitable for family use when the owner does not plan to upgrade. Therefore, they are often used in production. The housing is generally rectangular and made of metal. They are equipped with electronic components, and connection ports and various indications are located on the back and front of the case. They are installed in 19 racks, one above the other. In this case, the rear wall of the upper housing becomes the upper wall of the lower housing. Now, this component has become the main component for installing telecommunications equipment and servers.

See also: Principles of Laser Cutting: Techniques and Equipment Used

The overall block is the designer used to build the computer. In this case, the component is already installed in it. The owner of such a device can simply replace the RAM, processor or hard drive in it. But, for example, it is almost impossible to replace the motherboard. In any case, this will cause serious difficulties.

If the owner plans to change it to a more modern candy in a few years, they can buy a home candy bar because upgrading is difficult. But for organizations, monolithic blocks are convenient because they make it possible to quickly create several computer-equipped workplaces.

2. AT and Slim.

At the end of the last century, at the beginning of the computer era, PC cases were manufactured according to AT standards. Today, this is a thing of the past, and the ATX standard is now used. But on this basis, they created samples for Slim and Ultraslim. These are ultra-thin and ultra-thin shells. Their main purpose is to look stylish. Otherwise, they will not be very convenient because installing serious fillers in them will not work-the space is too small.

AT and Slim

This shell standard is very popular in Western countries, but not in Russia. The space saved by the manufacturer has attracted Western buyers. After all, you can put the computer system components on the table and the monitor on top of it.

Some of the most commonly used types of horizontal metal PC cases are:

Desktop computer (desktop computer) with a size of 533x419x152 mm;

Footprint (floor) 408x406x152 mm;

SlimLine (thin type), the size is 406x406x101 mm;

UltraSlimLine (ultra-thin) 381x352x75 mm.

3. The vertical (tower) metal casing of the notebook computer.

A computer case placed vertically in space is called a "tower" or tower. Experts believe that in this case, in order to quickly cool the PC, the components should be placed as easily as possible.

Vertical (tower) metal computer case

In this case, consumers will find the most convenient option for themselves. It may be the case of modern servers, or only for devices with typewriter capabilities.

Consider the most popular ATX vertical chassis in Russia:

They are also called "full towers". The size in this case is 200x600x1000 mm. There are 5.25" and 3.5" bays inside, the first of which is used to accommodate optical drives (4-9 can be), and the second is for hard drives (6-12). In addition, seven expansion cards can be placed in the tower. This is the sound card, receiver, etc.

In addition to the above, in this case, you can also place an ATX motherboard (standard size) so that you can assemble a server or a high-performance gaming computer. There will be enough space to accommodate various other equipment.

BigTower or "Big Tower". The size in this case is 190x482x820 mm. In addition to full towers, they can also provide full-size ATX motherboards, but there is nowhere to install other equipment. In this case, it can also be used to create a game computer.

These are the most famous and commonly used standard hulls in our country-the "middle tower". Their dimensions are 183x432x490 mm. This kind of case can accommodate power supply equipment, ATX board. RAM (2 slots) and hard drives (several) can be built-in. This is the most versatile case because it can be used to assemble office computers or powerful gaming PCs, or you can make a media center for your own home.

The size of this "tower" is 178x432x432 mm. The chassis is very small and can be assembled into a home computer or home theater. Such a body takes up very little space.

MicroTower is the smallest vertical metal enclosure. The size of this baby is even smaller. It is suitable for low-power devices with motherboards with built-in peripherals.

Manufacturing technology of sheet metal shell

Let us consider the various methods used to manufacture metal casings used to manufacture electronic devices.

Cold plate stamping.

The housing of the electronic equipment (CEA) is made by cold stamping sheet metal. Although this method has been used for a long time, it has not lost its relevance. Its essence is to use special stamps. It is used for the production of mass products and the start of mass production. The role of the mold is to form different parts of the body. For small batches and single products, this technique is impractical because of the high cost of manufacturing stamps.

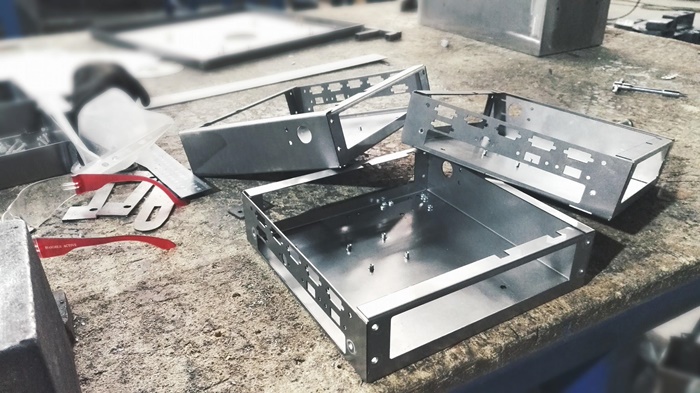

Sheet metal processing.

Moreover, in many cases, the housings of electronic devices are made by sheet metal processing methods. This technology is used for the production of small batches of products. For example, the developer chose a specific metal housing design. Then, he needs to decide how to do it: commission a separate development based on certain requirements or use a ready-made model to make some adjustments for himself.

Choose the method of manufacturing the shell according to the batch size. When planning a large number of instruments, individual design and use of cold stamping methods in manufacturing should be considered. In the production of small and medium batches, it is worth using ready-made solutions. At the same time, the sheet metal processing of the material will help make necessary changes to the design during the production process, after which the product will completely correspond to the manufactured equipment.

Use CNC machine tools.

The housing of electronic equipment can also be produced on CNC machines (computer numerical control). This is a fairly popular method. With its help, small batches of cases and single copies can be made. It should be noted that the cost of such products is very low. It is believed that with this output, the use of CNC equipment is economically feasible. These machines are compact and do not require a large footprint, which makes manufacturing products cheap.

Moreover, the use of CNC equipment can reduce the number of experts working for it. This means that the human factor in production is reduced, so that the product is of high quality, but the defects are actually eliminated. These advantages make it possible to use the device not only in small-scale housing production, but also in the manufacture of large-volume products.

Ergonomics and sheet metal housing cooling

Earlier, we mentioned one of the main functions of a computer case-to dissipate heat from the heating element of the system unit. The increase in the number of fans cannot prevent overheating due to the specific cooling of PC components. The best results can be achieved by placing the fan correctly and thus organizing the movement of air inside the device.

There is no need to evaluate the ventilation system installed on the PC by the number of coolers. With their help, heat is dissipated from the heating element. If the cooling system is not installed correctly, the hot air currents will collide with obstacles or each other, making it impossible to cool the equipment.

Below is a photo of a relatively reasonably constructed ventilation scheme for a metal computer case. After careful inspection, you will find one or several low-speed coolers (at the input) installed in the case. They suck cool indoor air into the system unit. A smaller and more powerful fan is placed behind (at the outlet) to blow out the heated air. This circuit allows you to generate thrust. Therefore, the metal body is a cooling turbine, in which cold air enters the heating element, they are cooled, and then the system guides the heated air to the outside.

See also: bent aluminum tube

The proposed solution can also be supplemented with coolers located near the side walls and the top wall. They must blow out the air.

Therefore, in order to create a system that properly cools the metal PC case components, you should remember:

Meer waaiers beteken nie beter hitte-afvoer nie.

Die beweging van lug in een rigting moet georganiseer word, nie in lugstrome verdeel word nie.

Vanuit die skoolkurrikulum kan u weet dat warm lug altyd sal styg, terwyl koue lug sal val, en dus moet u nie vertikale stelsel-eenhede horisontaal plaas nie.

Los kabels binne die toestel belemmer lugsirkulasie.

'N Waaier met groot lemme en lae spoed sal die lugvloei verhoog.

Die hoeveelheid lug wat die waaier binne een minuut in die onderstel kan blaas, moet deeglik oorweeg word.

Ergonomie en verkoeling van plaatmetaalbehuising

Hierdie parameter word CFM-kubieke voet per minuut genoem. Daar moet seker gemaak word dat die lug in die hek voortdurend sirkuleer. Om te bereken watter waaier hierdie funksie kan bied, moet u:

Calculate the area of the case. To do this, multiply its length by its width and height.

Calculate the CFM of the cooler.

For example, the volume of a 253x502x563mm box is 2.52 cubic feet. The air in the box should be changed every 2 seconds, so a 70 CFM cooler is required. Sometimes, you will find a PC with vents that cool the processor in the form of a tube on the side of the case. They are of little benefit, but they are more harmful because they create obstacles to the natural flow of air. They should be removed and fixed in the wire casing.

Dust filters (such as ducts) also cannot help the fan to cool the components of the computer. Within 2-3 months from the date of installation, they will soon be clogged with indoor dust, so their performance is very low. In addition, the mesh clogged with dust can interfere with the movement of the air, causing the device to overheat. Therefore, the productivity of this equipment is low.

The screws that used to support all PC components have gradually become history. During the computer assembly/disassembly process, a large number of screws are inconvenient to use. Everyone who has analyzed a system analyzer knows this.

This is the reason why manufacturers have long used plastic buttons and "bases" for hard drives to complete computer technology.

Daarbenewens word klampe, proppe, bykomende bevestigingsmiddels, ens. Gebruik, wat die boks gemakliker maak. Die ergonomiese onderstel help u om komponente te vervang en u rekenaar intern en ekstern op te gradeer.

Dit is die moeite werd om aandag te skenk aan die kabels wat in die onderstel geleë is. Die doeltreffendheid van verkoelingstelsels hang af van die ligging daarvan. Ons moet egter nie die gemak van die koppeling van nuwe toestelle en toestelle vergeet nie.

Waarom ons kontak?

Ons respekteer alle klante en voer take van enige skaal streng uit.

Ons produksiefasiliteite stel ons in staat om verskillende materiale te verwerk:

Nie-ysterhoudende metale;

gietyster;

vleklose staal.

As u die bestelling voltooi, sal ons kundiges alle bekende metaalverwerkingsmetodes gebruik. Die nuutste generasie moderne toerusting kan in die grootste mate aan die oorspronklike tekeninge voldoen.

Om die werkstuk nader aan die skets wat deur die klant voorgestel word, te maak, gebruik ons kundiges universele toerusting wat ontwerp is vir poleergereedskap vir juweliersware vir besonder ingewikkelde bewerkings. In ons vervaardigingswerkswinkel word metaal 'n smeebaar materiaal wat gebruik kan word om enige werkstuk te vervaardig.

Die voordeel van kontak met ons kundiges is dat hulle aan GOST en alle tegniese standaarde voldoen. In elke stadium van die werk word streng gehaltebeheer uitgevoer, dus ons waarborg dat ons klante sorgvuldig geïmplementeerde produkte voorsien.

Danksy die ervaring van ons vakmanne is die produksie 'n modelproduk wat aan die veeleisendste vereistes voldoen. Terselfdertyd begin ons vanuit 'n sterk materiële grondslag en fokus ons op die ontwikkeling van innoverende tegnologieë.

Ons werk saam met kliënte in verskillende streke. As u 'n bestelling vir metaalverwerking wil plaas, is ons bestuurder altyd gereed om na alle situasies te luister. As dit nodig is, kan ons kliënte gratis professionele konsultasie gee.