金属シェル加工:種類と製造特性

2020-09-19金属シェル加工:種類と製造特性

資料に関連する問題:

- 金属ケーシングの材料について

- プレートメタルシェルのタイプ

- 板金シェルの製造技術

- 板金エンクロージャの人間工学と冷却について

金属シェル処理は、最新のコンピューター、より正確にはシステムユニットを作成するために使用されます。 各システムユニットには、PC全体の操作を担当する多数の要素が含まれています。 これらには、電源ユニット、マザーボード、光学ドライブ、ハードドライブなどが含まれます。

There are many types of sheet metal boxes, which are manufactured according to their technology. In addition, it is important to provide cooling and ergonomics in the equipment. The type of metal made into the case plays an important role. Generally, there are many nuances in the process of manufacturing computer equipment. If you want your computer to work normally for a long time, you should understand them.

Materials used to make metal casings

In the manufacture of metal casings for computer technology, materials with certain characteristics are required, which makes it difficult to choose. They must provide the required protection for computer components from vibration and any mechanical influences. At the same time, they should contribute to the rapid cooling of heat-generating components during equipment operation. Therefore, aluminum is usually selected for the manufacture of high-grade housings,

The reason lies in the characteristics of the metal. It has the best heat dissipation and heat dissipation capacity. Copper has the same quality, but aluminum is lighter and cheaper. However, the metal shells of plates made of SECC (special steel) coated with electro-galvanizing solutions have been more widely used. They are used in the mid-price segment of computer technology.

Recently, aluminum has become the most commonly used housing material due to its value. The structural properties of aluminum and its appearance provide designers with huge opportunities

プレートメタルシェルのタイプ

Mass production requires strict manufacturing standards for various types of products. This applies to almost all industrial fields, and computer technology manufacturing is no exception. Compliance with the standard not only allows you to be confident in the strict parameters of the components used, but also allows you to assemble equipment from components designed and produced by a large number of suppliers.

The conditions for further use constitute the standard size of the product. For ease of use, the housing has certain characteristics. There is still no perfect standard. 25 standard sizes are now used. These are not only metal shells for mass production, but also single shells designed to solve special problems. The latter is specifically needed by narrow experts. Most people's interests extend to the former, and we will consider them in the future.

1. Single piece.

It is a single unit of PC system equipment, monitors, speakers and other components. Except for the system unit, the latter is usually an external device, but not in this case. The size of the product is not standardized and only meets the manufacturer's standards.

Monolith

The most famous is Apple devices. These monolithic "Macs" are still one of the most reliable and beautiful products on the market.

The advantage of this situation is its compactness, that is, the smallest space occupied by the entire device. However, this is also its disadvantage. Such equipment is difficult to upgrade. Due to the lack of space inside the shell, it is impossible to change the packaging, make improvements, and install more powerful components.

This is why the entire house is actually not suitable for family use when the owner does not plan to upgrade. Therefore, they are often used in production. The housing is generally rectangular and made of metal. They are equipped with electronic components, and connection ports and various indications are located on the back and front of the case. They are installed in 19 racks, one above the other. In this case, the rear wall of the upper housing becomes the upper wall of the lower housing. Now, this component has become the main component for installing telecommunications equipment and servers.

See also: Principles of Laser Cutting: Techniques and Equipment Used

The overall block is the designer used to build the computer. In this case, the component is already installed in it. The owner of such a device can simply replace the RAM, processor or hard drive in it. But, for example, it is almost impossible to replace the motherboard. In any case, this will cause serious difficulties.

If the owner plans to change it to a more modern candy in a few years, they can buy a home candy bar because upgrading is difficult. But for organizations, monolithic blocks are convenient because they make it possible to quickly create several computer-equipped workplaces.

2. AT and Slim.

At the end of the last century, at the beginning of the computer era, PC cases were manufactured according to AT standards. Today, this is a thing of the past, and the ATX standard is now used. But on this basis, they created samples for Slim and Ultraslim. These are ultra-thin and ultra-thin shells. Their main purpose is to look stylish. Otherwise, they will not be very convenient because installing serious fillers in them will not work-the space is too small.

AT and Slim

This shell standard is very popular in Western countries, but not in Russia. The space saved by the manufacturer has attracted Western buyers. After all, you can put the computer system components on the table and the monitor on top of it.

Some of the most commonly used types of horizontal metal PC cases are:

Desktop computer (desktop computer) with a size of 533x419x152 mm;

Footprint (floor) 408x406x152 mm;

SlimLine (thin type), the size is 406x406x101 mm;

UltraSlimLine (ultra-thin) 381x352x75 mm.

3. The vertical (tower) metal casing of the notebook computer.

A computer case placed vertically in space is called a "tower" or tower. Experts believe that in this case, in order to quickly cool the PC, the components should be placed as easily as possible.

Vertical (tower) metal computer case

In this case, consumers will find the most convenient option for themselves. It may be the case of modern servers, or only for devices with typewriter capabilities.

Consider the most popular ATX vertical chassis in Russia:

They are also called "full towers". The size in this case is 200x600x1000 mm. There are 5.25" and 3.5" bays inside, the first of which is used to accommodate optical drives (4-9 can be), and the second is for hard drives (6-12). In addition, seven expansion cards can be placed in the tower. This is the sound card, receiver, etc.

In addition to the above, in this case, you can also place an ATX motherboard (standard size) so that you can assemble a server or a high-performance gaming computer. There will be enough space to accommodate various other equipment.

BigTowerまたは「ビッグタワー」。 この場合のサイズは190x482x820mmです。 フルタワーに加えて、フルサイズのATXマザーボードを提供することもできますが、他の機器を設置する場所はありません。 この場合、ゲームコンピュータの作成にも使用できます。

これらは、私たちの国で最も有名で一般的に使用されている標準的な船体である「ミドルタワー」です。 それらの寸法は183x432x490mmです。 この種のケースは、電源装置、ATXボードを収容できます。 RAM(2スロット)とハードドライブ(いくつか)を内蔵できます。 これは、オフィスのコンピューターや強力なゲーム用PCの組み立てに使用できるため、または自宅用のメディアセンターを作成できるため、最も用途の広いケースです。

この「タワー」のサイズは178x432x432mmです。 シャーシは非常に小さく、ホームコンピュータまたはホームシアターに組み立てることができます。 そのような体はほとんどスペースを取りません。

MicroTowerは、最小の垂直金属筐体です。 この赤ちゃんのサイズはさらに小さいです。 周辺機器を内蔵したマザーボードを搭載した低電力デバイスに適しています。

板金シェルの製造技術

電子機器の製造に使用される金属ケーシングの製造に使用されるさまざまな方法を考えてみましょう。

Cold plate stamping.

The housing of the electronic equipment (CEA) is made by cold stamping sheet metal. Although this method has been used for a long time, it has not lost its relevance. Its essence is to use special stamps. It is used for the production of mass products and the start of mass production. The role of the mold is to form different parts of the body. For small batches and single products, this technique is impractical because of the high cost of manufacturing stamps.

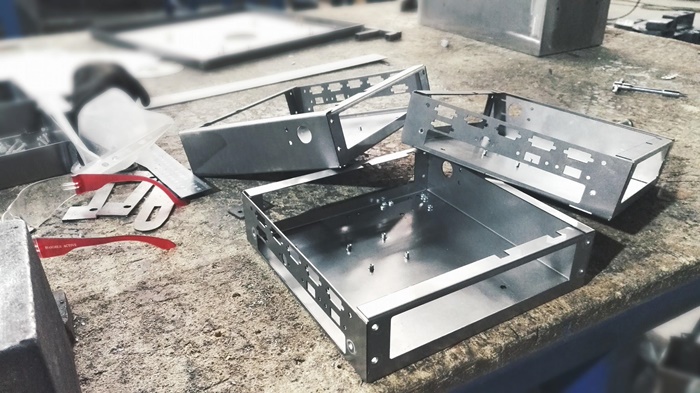

Sheet metal processing.

Moreover, in many cases, the housings of electronic devices are made by sheet metal processing methods. This technology is used for the production of small batches of products. For example, the developer chose a specific metal housing design. Then, he needs to decide how to do it: commission a separate development based on certain requirements or use a ready-made model to make some adjustments for himself.

Choose the method of manufacturing the shell according to the batch size. When planning a large number of instruments, individual design and use of cold stamping methods in manufacturing should be considered. In the production of small and medium batches, it is worth using ready-made solutions. At the same time, the sheet metal processing of the material will help make necessary changes to the design during the production process, after which the product will completely correspond to the manufactured equipment.

Use CNC machine tools.

The housing of electronic equipment can also be produced on CNC machines (computer numerical control). This is a fairly popular method. With its help, small batches of cases and single copies can be made. It should be noted that the cost of such products is very low. It is believed that with this output, the use of CNC equipment is economically feasible. These machines are compact and do not require a large footprint, which makes manufacturing products cheap.

さらに、CNC機器を使用すると、そのために働く専門家の数を減らすことができます。 これは、生産における人的要因が減少し、製品が高品質になることを意味しますが、実際には欠陥は排除されます。 これらの利点により、小規模な住宅生産だけでなく、大量生産にも使用できます。

人間工学と板金ハウジングの冷却

前述したように、コンピュータケースの主な機能の1つは、システムユニットの発熱体から熱を放散することです。 ファンの数を増やしても、PCコンポーネントの特定の冷却による過熱を防ぐことはできません。 最良の結果は、ファンを正しく配置し、デバイス内の空気の動きを整理することで達成できます。

There is no need to evaluate the ventilation system installed on the PC by the number of coolers. With their help, heat is dissipated from the heating element. If the cooling system is not installed correctly, the hot air currents will collide with obstacles or each other, making it impossible to cool the equipment.

Below is a photo of a relatively reasonably constructed ventilation scheme for a metal computer case. After careful inspection, you will find one or several low-speed coolers (at the input) installed in the case. They suck cool indoor air into the system unit. A smaller and more powerful fan is placed behind (at the outlet) to blow out the heated air. This circuit allows you to generate thrust. Therefore, the metal body is a cooling turbine, in which cold air enters the heating element, they are cooled, and then the system guides the heated air to the outside.

See also: bent aluminum tube

The proposed solution can also be supplemented with coolers located near the side walls and the top wall. They must blow out the air.

Therefore, in order to create a system that properly cools the metal PC case components, you should remember:

More fans does not mean better heat dissipation.

The movement of air in one direction must be organized, not divided into air streams.

From the school curriculum, you can know that warm air will always rise, while cold air will fall, so you should not place vertical system units horizontally.

Loose cables inside the device will hinder air circulation.

A fan with large blades and low speed will increase air flow.

The amount of air that the fan can blow into the chassis in one minute must be carefully considered.

Ergonomics and sheet metal housing cooling

This parameter is called CFM-cubic feet per minute. It must be ensured that the air in the enclosure circulates continuously. To calculate which fan can provide this function, you should:

Calculate the area of the case. To do this, multiply its length by its width and height.

Calculate the CFM of the cooler.

For example, the volume of a 253x502x563mm box is 2.52 cubic feet. The air in the box should be changed every 2 seconds, so a 70 CFM cooler is required. Sometimes, you will find a PC with vents that cool the processor in the form of a tube on the side of the case. They are of little benefit, but they are more harmful because they create obstacles to the natural flow of air. They should be removed and fixed in the wire casing.

Dust filters (such as ducts) also cannot help the fan to cool the components of the computer. Within 2-3 months from the date of installation, they will soon be clogged with indoor dust, so their performance is very low. In addition, the mesh clogged with dust can interfere with the movement of the air, causing the device to overheat. Therefore, the productivity of this equipment is low.

The screws that used to support all PC components have gradually become history. During the computer assembly/disassembly process, a large number of screws are inconvenient to use. Everyone who has analyzed a system analyzer knows this.

This is the reason why manufacturers have long used plastic buttons and "bases" for hard drives to complete computer technology.

In addition, clamps, plugs, additional fasteners, etc. are used, which makes the box more convenient. The ergonomic chassis helps you replace components and upgrade your computer internally and externally.

It is worth paying close attention to the cables located inside the chassis. The efficiency of cooling systems depends on their location. However, we must not forget the convenience of connecting new devices and devices.

Why contact us

We respect all customers and strictly execute tasks of any scale.

Our production facilities enable us to process various materials:

Non-ferrous metals;

cast iron;

stainless steel.

When completing the order, our experts will use all known metal processing methods. The latest generation of modern equipment can conform to the original drawings to the greatest extent.

In order to make the workpiece closer to the sketch proposed by the customer, our experts use universal equipment designed for jewellery polishing tools for particularly complex operations. In our production workshop, metal becomes a malleable material, which can be used to manufacture any workpiece.

The advantage of contacting our experts is that they meet GOST and all technical standards. In each stage of work, strict quality control is carried out, so we guarantee to provide customers with carefully implemented products.

私たちの職人の経験のおかげで、出力は最も厳しい要件を満たすモデル製品です。 同時に、私たちは強力な材料基盤から始めて、革新的な技術の開発に焦点を合わせています。

さまざまな地域のお客様と協力しています。 金属加工をご注文の場合、当社のマネージャーがいつでもあらゆる状況に対応いたします。 必要に応じて、無料の専門家による相談をお客様に提供することができます。