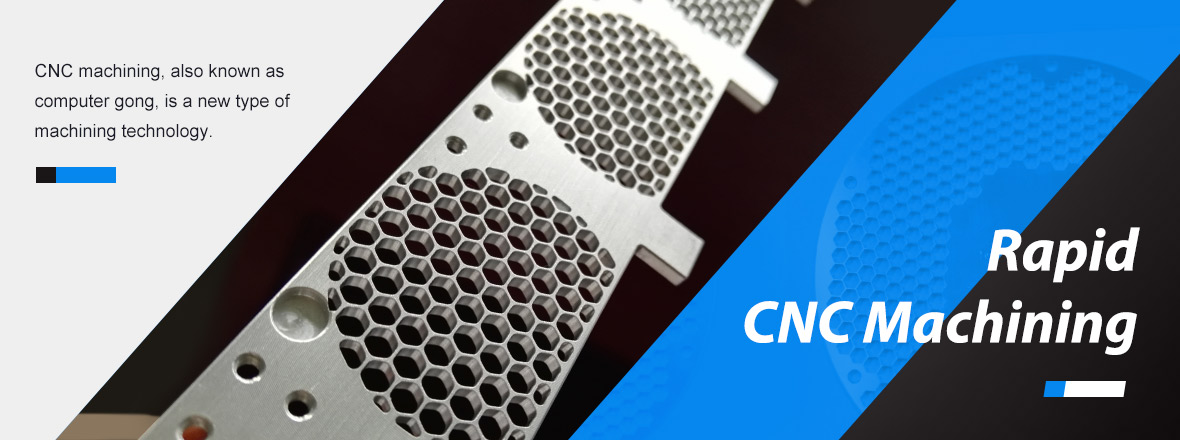

Быстрая обработка с ЧПУ

Быстрая обработка с ЧПУ

Essai specialize in rapid prototyping, sheet metal and low volume production of custom parts. Our international team of engineers and technicians use advanced equipment and techniques like 3D metal printing, multi-axis CNC machining and plastic injection molding, to turn your designs into reality quickly, accurately and at a great price.

Мы используем новейшее программное обеспечение, современные станки с ЧПУ, современное измерительное оборудование и квалифицированных специалистов, конкурентоспособные предложения, быструю доставку и отличное качество. Essai получила широкое признание клиентов по всему миру.

Производственная мощность:

Essai can process workpieces ranging in size from a few millimeters to complex components such as automotive dashboards. There are always a variety of stocks of plastics and metal blanks, such as Aluminum, stainless steel, carbon steel, PC, ABS, POM ... and so on, to meet many customer needs. If needed, we can also quickly purchase more exotic materials for special projects. Most Essai prototypes are produced by CNC, so they ensure accuracy equal to or better than injection molding and allow customers to bring their own materials to make their prototypes.

В то же время Essai может также предоставить клиентам сопутствующие услуги последующей обработки и обработки поверхности, такие как удаление пыли и окисление. Наши возможности обработки металлов с ЧПУ позволяют производить различные типы деталей с разными размерами для многих отраслей, включая автомобильную, аэрокосмическую, морскую, строительную, научную, медицинскую и т. Д. Благодаря новейшему программному обеспечению CAD / CAM и опыту обработки большинства металлов мы можем производить высокоточные детали в малых и больших количествах. Мы также можем предоставить услуги по полировке, включая полировку, хромирование, золочение, нанесение порошкового напыления, горячее погружение и анодирование.

Before starting to manufacture any components, our dedicated account managers and project engineers will discuss the required performance of prototype parts with customers to ensure that only the most suitable materials, processes, production, processing, and transportation methods are used; if your product quantity is not large, The time is short, and high-end requirements, please choose this processing technology-CNC Machining, choose us Essai, we will give you professional services from your inquiry.

Преимущества станков с ЧПУ:

- Significantly reduce the number of tooling, complex parts do not require complex tooling. If you want to change the shape and size of the part. You only need to modify the part processing program. This is suitable for the development and modification of new products.

- The processing quality is stable, the processing accuracy is high, and the repeatability is high. It meets the processing requirements of the aircraft.

- In the case of multi-variety and small batch production, the production efficiency is high. They can reduce the time for production preparation, machine tool adjustment and process inspection. And reduce the cutting time due to the use of the optimal cutting amount.

- Multi-coordinate linkage is possible. It can process complex profiles that are difficult to process by conventional methods. And can even process some unobservable processing parts.

- When machining parts change, generally only need to change the NC program, which can save production preparation time.

- The machine tool itself has high precision and rigidity. It can choose favorable processing volume and high productivity (generally 3 to 5 times that of ordinary machine tools).

- Высокая степень автоматизации станков может снизить трудоемкость.

Disadvantages of CNC machining:

- Machine tool equipment is expensive and requires a high level of maintenance personnel.

- But its processing route is not easy to control and is not as intuitive as ordinary machine tools.

- It has higher requirements for the quality of operators and higher technical requirements for maintenance personnel.

Наши услуги:

1) Станок с ЧПУ:

Трехосевой ЧПУ

Четырехосевой ЧПУ

Пятиосевой ЧПУ

Токарный станок с ЧПУ

Лазерная резка

Листовой металл

2) Быстрое прототипирование: 3D-печать/SLS/SLA/вакуумное литье

3) Сжатие кремния

4) Мелкосерийное производство и сборка;

5) sheet metal part / stamping

Обработка поверхности:

Полировка, покраска, анодирование, гальваника, пескоструйная обработка, шелкография, лазерная резьба

Мы обслуживаем промышленность:

Автомобильная промышленность, бытовая техника, ареокосмическая отрасль, бытовая электроника, медицина, оборона, игрушки и т. д.

материалы по теме:

1) Пластик - АБС, ПММА, ПК, ПП, ПЭ, ПОМ и т. д.

2) Металл - алюминий, нержавеющая сталь, латунь, цинк и т. Д.

3) Другие - резина, кремний и т. Д.

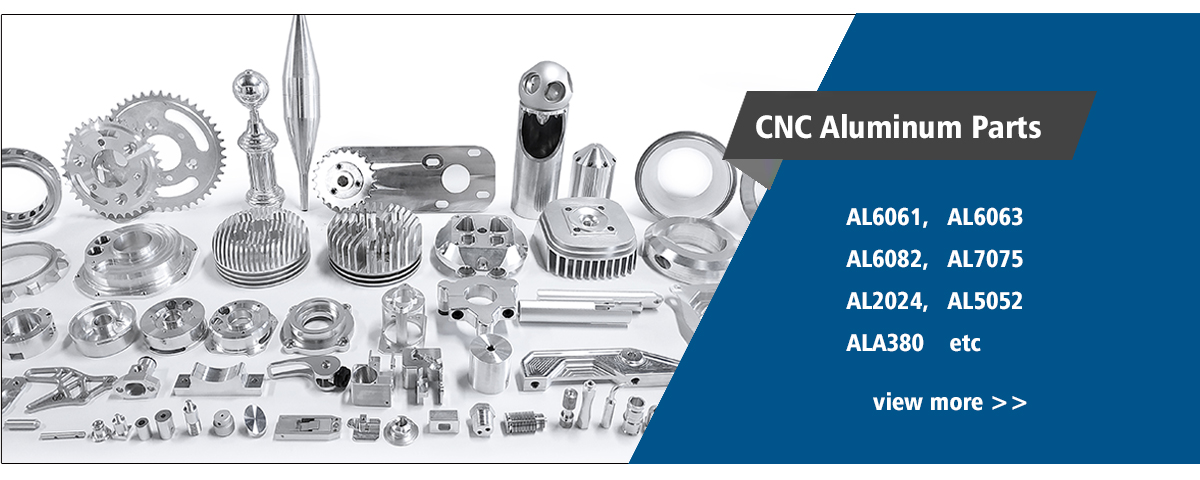

You can use all kinds of matel and plastic raw material, usually we use as below:

- Carbon steel / cold rolled sheet / hot rolled sheet / spcc.

- Stainless steel (201, 304, 316).

- Aluminium steel (5052, 6061, 7075).

- Brass / plactic ABS, PMMA, PC, PP, PE, POM / copper, etc.

Rapid CNC Machining Capabilities as follows: |

||

| Applications | Machine components | Medica devices |

| Security components | Valve devices | |

| Consumer components | Electronic housings | |

| Furniture components | Motor housings | |

| Smart lock components | Fittings / Contectings | |

| Lighting components | Furniture components | |

| Industry field | Medical | Аэрокосмическая промышленность |

| Security &Protection | Industrial | |

| Consumer | Packaging | |

| LED Lighting | Architectural | |

| Electronic | Household appliances | |

| Furniture | Office appliances | |

| Telecom | Военные | |

| Agricultural | Automobile | |

| Production Volume | Prototype | Low Volume |

| Small quantity | Mass production | |

| Metal material | Обработка алюминиевых | Углеродистая сталь |

| Bronze | Нержавеющая сталь | |

| Медь | Alloy Steels | |

| Латунь | Iron | |

| Plastic material | ABS | PVC |

| PP | PE | |

| PC | PBT | |

| POM | PEEK | |

| PVC | PSU | |

| PMMA | Nylon | |

| Part Surface | Mirror Polish | Anodizing |

| Plated | Passivation | |

| Painting | Electrophoretic coating | |

| Powder coating | Non- stick debron coating | |

| Industry standard | ISO 9001-2008 | TS16949 |

| Оборудование | 5X 400X400mm high speed CNC / FANUC | |

| 2X 500X500MM high speed CNC / MORI SEIKI, | ||

| 1X 600x600MM high speed CNC/MAKINO | ||

| 20X 500X500mm high speed CNC/ Taiwan TAIKAN | ||

| 5X 600X600mm high speed CNC /Taiwan TAIKAN | ||

| 3X 800X800mm high speed CNC /Taiwan TAIKAN | ||

| Advantages | Shorter delivery time | Professional team |

| Competitive price | Good communication | |

| Tight tolerance | Good quality control | |

| File format | 2D format | 3D format |

| DWG | STEP | |

| IGES | ||

| DXF | X_T | |

| Packaging | Bubble | K-K carton / wood case |

| PE Foam | woodex /Plastic pallet | |

| Lead time | Normally 2-4 weeks | |

| But some of them depend on the quantites request. | ||

| Shipping | By air | |

| By express (DHL,UPS, FedEX) | ||

| By sea | ||

Добро пожаловать, чтобы начать свой бизнес прямо сейчас!

Свяжитесь с нами