Advantages and Disadvantages of Stamping Techniques

Currently, the sheet metal stamps market is booming. It is due to the wide range of options that customizations allow you to create.

Choosing the type of stamping and the best technique to prepare your products can be a difficult choice. But we are here to help you.

Keep reading the post and find out the advantages and disadvantages of sheet metal stamps. It is to clear up any doubts you may have about it!

Discover the sheet metal stamps techniques and choose the best one!

There are several stamping techniques available on the market. Hence, you can produce your personalized products. We have from centuries-old techniques, such as Serigraphy, to the most modern and digital ones, such as Silk Digital. Besides these, there is Transfer and Sublimation.

Direct or indirect stamping sheet metal stamps?

First of all, it is necessary to know the difference between the two stamping processes. These are direct or indirect stamping. As the names suggest, what differentiates these processes is the fact that the print is printed directly on the spot or goes through some process beforehand.

But how so?

Thinking practically: we can sheet metal stamps as an example of direct stamping. The print comes directly on the sheets. Already Transfer and Sublimation require that the pattern is printed on a particular sheet to then be passed to the part. In this case, indirect stamping takes place.

Each of the stamping techniques has its peculiarities, advantages and disadvantages. Check which ones they are!

Screen stamping

As we said, it is the oldest process that exists. Since ancient times, there has been a stencil in the East for applying patterns to various types of surfaces. In China, sheet cutouts were common as masks for prints, mainly on fabrics.

In Japan, the stencil process gained prominence when the samurai's armour, horse coverings and standards had emblems applied through this technique.

What is modern sheet metal stamps process?

In the modern sheet metal stamps process, canvases are common with the cutouts that will be part of the print. In this way, when the canvases are placed on the piece to be printed, the ink will only pass through the cut-out spaces. It is a technique that requires manual work.

To apply the ink to the fabric, boards are common that will keep the sheets taut. Then, the canvas has support on the area to be printed. And the person responsible for stamping the sheets then runs a squeegee over the canvas. It is to evenly distribute the ink on the fabric.

Why sheet metal stamps technique is not time consuming?

This technique is one of the most time-consuming, since, for each color of the print, a different canvas we require. This also makes screen stamping an expensive process for ordering small quantities. However, if they are ordered in large quantities, Screen Stamping ends up becoming more affordable, since the cost of the screens is fixed.

Benefits

Among all the stamping techniques, Serigraphy is one of the most resistant, in addition to having a low cost of equipment to be common in production. Screen stamping still works very well on dark fabrics.

Disadvantages

Because you need a screen for each color of the print, there is a limitation on the amount that can be common in the print. In addition, to offset the expense of screens, the order must be in large quantities.

How does transfer method work in sheet metal stamps?

Transfer, as the name implies, means “transfer”. It's simple: the print is transferred from a sheet to the sheets. It is not necessary to have a lot of resources to produce and the cost of sheet metal stamps is not high.

You will only need a printer and a specific transfer sheet. After the print is done, you just need to press the sheet against the sheets using a heat press. Thus, the image will be transferred from the sheet to the fabric.

You know that feeling that the print area is harder than the rest of the fabric? It's because it's not a process that's dyeing the sheets, it's “gluing a sticker” to it.

Benefits of sheet metal stamps technique

As it is a relatively simple process, it does not need a minimum amount of parts to be made. Taking the entire process into account, the cost is relatively low, and the profit margin can be very high, if you are interested in selling what you produce.

Disadvantages

You can notice the appearance of adhesive glued to fabric, especially if the transfer is made on black sheets, even if the print finish is done in the best possible way. However, with the current technology present in some Transfer processes, this problem has been solved.

Why you need to choose best sheet metal stamps company?

The sheet metal stamps companies have a leading role in the industrial market, as it is through it that companies get parts in the correct measures for the development of its production processes. The service is widely common by different segments, including:

- Metallurgy;

- Electromechanics;

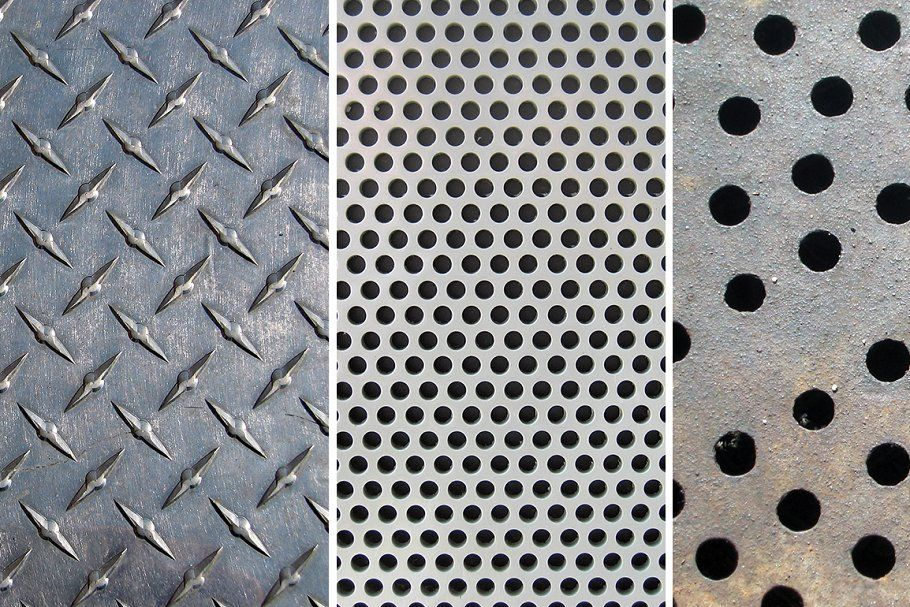

Stamping basically consists of molding metal sheets so that they acquire the determined format, according to the specifics of each project. This type of service works with the most varied types of metallic materials, such as: aluminum sheets, brass, copper, among others.

PRODUCT DIFFERENTIALS

The sheet metal stamps transformation processes comprise processes such as: bending, drawing and cutting, which make the piece the ideal format for use in final processes for the elaboration of different products?

One of the great advantages of this type of service is that it greatly facilitates the processes and can work with high volumes of parts, which can be manufactured in series. It is a necessity in the industrial segment.

Stamping sector is Highly Important

The stamping sector was developed to meet a demand from the Tooling Sector, which was to produce the parts after the tooling was ready, in this way we would have more control of the production processes and their improvements, giving full support to the preventive maintenance and repairs of the tooling.

In our sheet metal stamps production we have eccentric and hydraulic presses, with different tonnages depending on your application.