Types and methods of modern metal stamping

Metal stamping: technology features. It is an alternative method of plastic deformation of metal: cold and hot sheet and die forging. Moreover, this includes cold stamping technological operations.

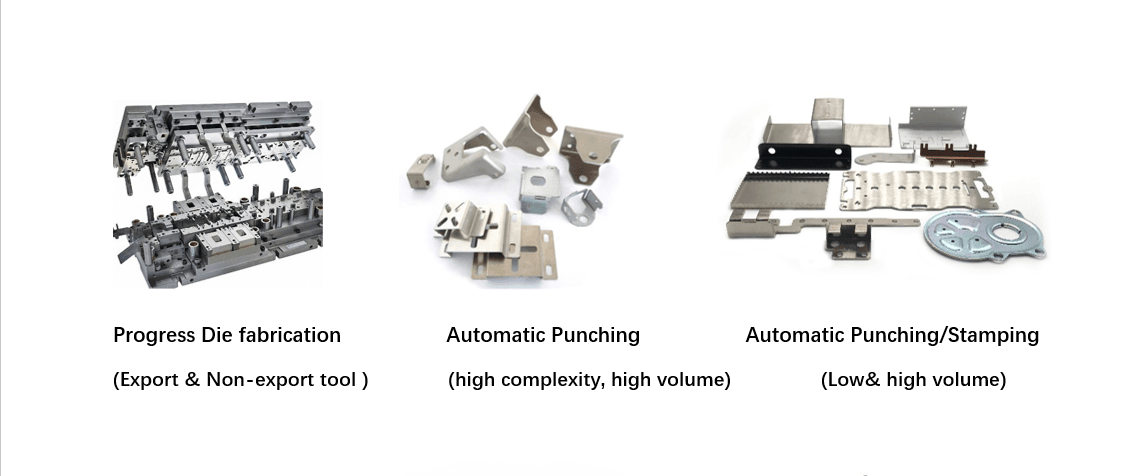

Used Press Equipment and Automatic Lines.

Stamping is a technological operation that controls process of changing the shape and size of a work piece under the influence of pressure. Moreover, the process comes by high productivity, and therefore is widely common in various industries.

The technology has a rich history, but its mechanization began in the 50s of the XIX century: machines began to connect to the process. Furthermore, it increases productivity and improved the quality of products. Metal stamping equipment makes it possible to produce various parts: from small elements of the clockwork to the components of aircraft.

Basically, sheet stamping is actively common in serial production. Using this technology, metal, plastic and other materials process is important. Furthermore, the process comes by high productivity, stability and accuracy.

Generally, cold forming is the most advanced forming method. As the name suggests, these are manufacturing operations without preheating the workpiece. Similarly, this approach improves the strength and surface finish of the stamping.

Table of contents

- 1Types of metal stamping technologies

- 1Sheet stamping

- 2Forging

- 3Technology of hot die forging (Essaii)

- 4Cold die forging method

- 2The essence and purpose of cold stamping of sheet metal

- 1Cold forming operations

- 3Classification of punching equipment

- 1Crank presses

- 2Hydraulic presses

- 3Radial forging presses

- 4Electromagnetic presses

- 4Automatic stamping lines

Types of metal stamping technologies

During its existence, many stamping methods have appeared. Similarly, mass production requires a special approach, where the speed and quality of product manufacturing are in the first place. In addition, hand stamping is now common exclusively privately, to create one-off pieces.

Before considering the methods of forming by pressure, consider other types of stamping:

- Magnetic pulse. To change the shape of the parts, short-term pulses of electric current are common.

- Isothermal stamping of parts. It is common for deformation of alloyed and heat-resistant steels. The peculiarity of the isothermal process is that the contact mold heats to the deformation temperature of the workpiece. Simultaneously, hydraulic presses are common as working equipment.

- Explosion metal stamping. A kind of impulse method. It is actively common in the field of aircraft production. The principle of operation comes on the transmission of the impact of the blast wave through air or water. As a result, the workpiece deforms, acquiring the shape of the common matrix.

In addition to production functions, the energy of the explosion is common as a drive for moving parts of equipment.

The technological process in which a product obtains by pressure on molten metal is called liquid stamping. Due to the high cost of matrices and punches, it is advisable to use the method only in mass production.

Sheet metal stamping

Stamping of sheet metal parts is common in mass production for the manufacture of three-dimensional or flat structures. Furthermore, the process of forming a finished product takes place using a special tool called a stamp. The technology of sheet stamping was common by ancient people. With its help, dishes, decorations and agricultural supplies appeared.

The workpiece processing process divides into two categories, which differ in operating temperature:

Cold stamping: This method is considered the most effective. It is common for the manufacture of vehicle body parts. Competent cutting helps to rationally use the main material. The best performance is easy to achieve using carbon and alloy steels, as well as copper and aluminum sheets.

Hot stamping: As the name suggests, this method involves preheating the workpiece. For this, flame or electric ovens are common. Technological operations of this method do not differ at all from the cold production method. The only caveat is the thickness of the sheet metal:

Using this method, hull elements are produced in the shipbuilding industry.

Bulk metal stamping

A kind of processing of parts by pressure. The peculiarity of the process lies in the use of blanks of the simplest geometric shape. This technology makes it possible to obtain a more complex product as a result of volumetric plastic deformation.

Hot stamping is characterized by an elevated temperature at which the process takes place. The degree of heating depends on the materials common. Unlike metal stamping liquid metal, the state of aggregation of the workpiece remains unchanged.

Let's consider the features of each process.

Hot die forging technology (Essaii)

Hot volumetric deformation of parts performs under the influence of temperature and pressure on the workpiece. Moreover, to obtain the required shape, the material heats and place in closed dies. Similarly, there is no gap between the common molds. Thus, the finished product forms in a closed cavity called a stream or engraving.

The approach comes by a low percentage of flash, but requires attention at the procurement stage. In addition, finished products differ in dimensional accuracy and surface quality.

Essaii technological process:

- The type of metal stampingis determined.

- A detailed drawing is being developed.

- Technologists calculate the number of transitions from the workpiece to the finished product.

- Moreover, an individual drawing is prepared for each intermediate stage.

- Similarly, select molds for transitions.

- Determine the parameters and method of heating the workpiece.

- Based on the requirements for the part, the necessary finishing procedures are determined.

Upon completion of the metal stamping project development, economists calculate the cost of the work. Compared to hot forging, Essaii has a much higher productivity and accuracy of work.

Furthermore, the requirements for the training of the equipment operator are not very strict. Similarly, the average training time for a specialist is 6 months.

The disadvantages include the limitation on the weight of the final product and the high cost of metal stamping equipment.

Cold die forging method for metal stamping

Calibrated rods or wire material are common as blanks for cold die forging. The technology makes it possible to obtain products of high precision and surface cleanliness. In addition, due to the absence of metal recrystallization, such parts are highly resistant to mechanical damage.

The main disadvantage of the technology considers being the excessive efforts that must come to obtain the finished metal stamping.