Revolutionary SLA 3D Printing and SLS 3D Printing Systems for The Win

Additive manufacturing is a phenomenal attestation to the swift evolution from analog to digital processes. Among the few renowned 3D printing technologies, SLA 3D Printing and SLS 3D Printing are eminent. SLA and SLS are two different techniques performing similar functions however concluding with different results.

3D printing has allowed medicine, manufacturing, education, agriculture and many more industries to revolutionize themselves.

At long last, all functional departments are applying 3D Printing. The journey of 3D printing has come a long way. 3D printing was once considered a mere fragment of the imagination is now visually representable. The whole process of printing is explained the same way it gets performed; a thin layer at a time.

SLA 3D Printing and SLS 3D Printing

Essentially additive manufacturing and 3D printing are umbrella terms, they include a variety of additive technologies. It is safe to assume that 3D printing is the way we will deal with hypothetical situation in the near future. Crafting structures out of thin air is an art we all have to become accustomed to.

Although 3D printing is not a novel innovation, its surge has occurred over the past few years. Boomers in question do not trust the innovative evolutions as much as the next generation do. This generation revels in technological shortcuts. In recent years’ 3D printing has invariably become more cost effective and accessible, diversity in technologies similar to SLA 3D Printing an SLS 3D printing has made this possible.

Advocates of 3D printing predict supremacy in regards to efficiency, time reduction, technique and much more. It is time to acknowledge 3D printing with all its glory intact. The digitally equipped future we once dreamt of is now within our grasp.

Embodiment of 3D Printing technology

There are numerous natures of 3D printing technology erupting all around. The layer by layer construction process of 3D printing is not confined to one technique. Since 3D printing has been around for a while, the phenomenon of it has been applied in different printing systems. Common 3D printing technologies comprise of:

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Polyjet

- Multi Jet Fusion (MJT)

- Electron Beam Melting (EBM)

- Direct Metal Laser Sintering (DMLS)

Understandably every industry has to figure out which 3D printing technology is applicable for their requirement. Assessing the pros and cons of each technology narrows the choice down. Of the many printing technologies SLA 3D Printing and SLS 3D Printing are prominent in Polymer 3D printing processes. SLA and SLS are common printing techniques however DMLS and EBM are the forerunners in metal 3D printing processes. Polymer 3D printing in addition to its constituents is familiar and widely practical.

The Metamorphosing of SLA 3D Printing and SLS 3D Printing

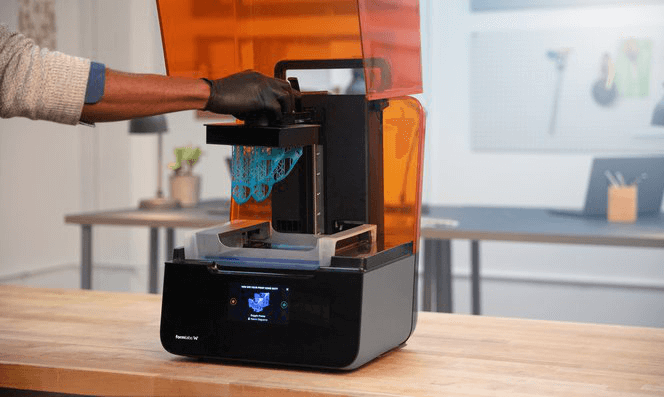

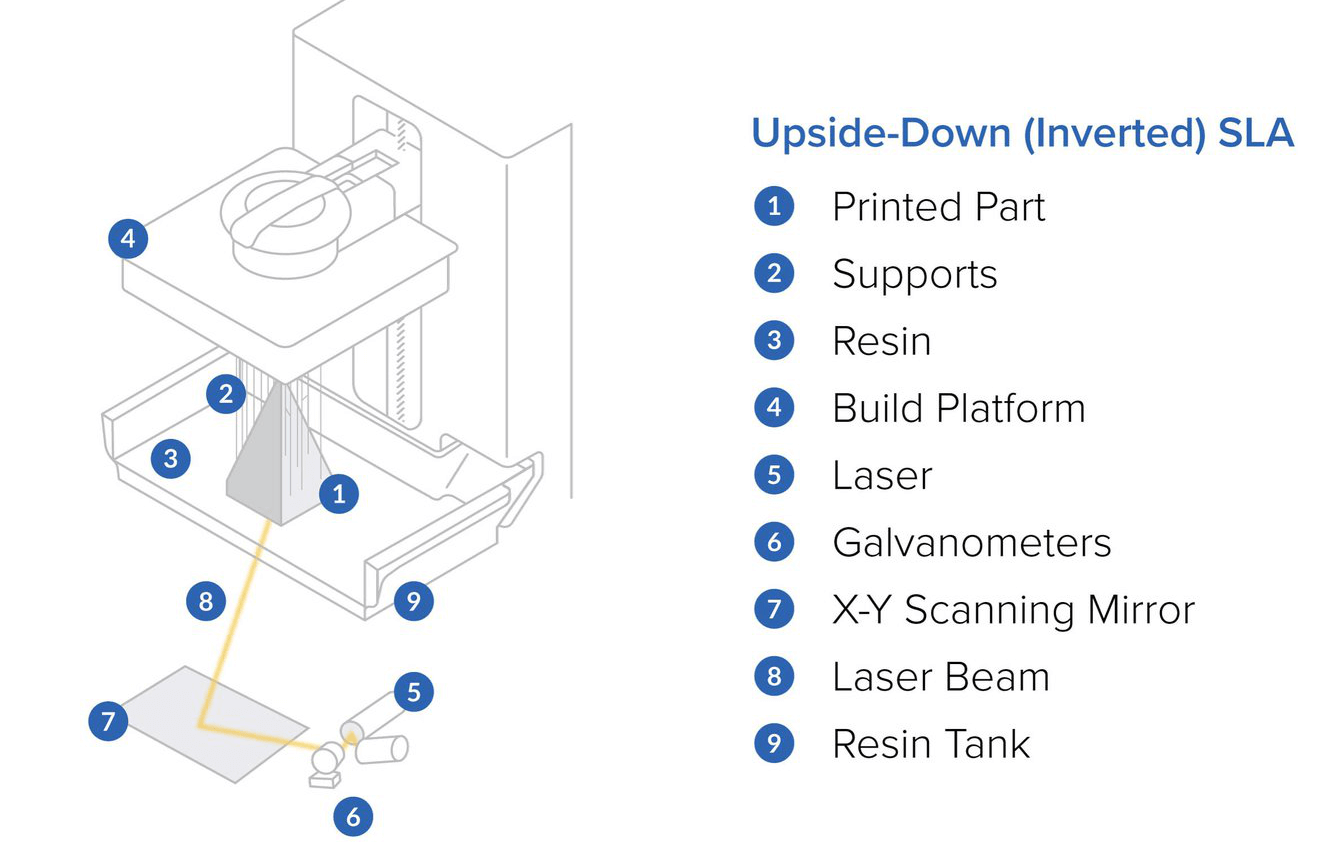

Stereolithography (SLA) is a 3D Printing process applied abundantly. Similar to other additive manufacturing technologies, it uses light-reactive thermoset material (resin) as a raw material. SLA was the first industrially used 3D printing mechanism. The process breakdown of an SLA printer is fairly simple.

The first step in SLA 3D Printing is conforming a design. The design is the basis on which the whole model rests. Any CAD software is adequate to create a hypothetical design and the digital model is further divided in to layers. The instruction to print digital design layers is forwarded to the printing machine.

The real magic happens in the SLA Printing machine. The machine is able to complete the printing process without aid. Most of the SLA printing process relies on the printing machine itself.

As soon as the printing process is finished the final product needs isopropyl alcohol rinsing in order to eliminate any uncured resin. The printing does not end after exiting the printing machine. Exiting parts of SLA have to be polished and scanned for any errors. These parts can later be painted, primed or fashioned to perform any function.

Designers favor SLA Printed 3D parts largely because they have a smooth surface and that is the only factor most designers are concerned with. Engineers and manufacturers are only concerned with the theory of the parts.

SLA parts are watertight; this aids the engineers who are experimenting on fluids. SLA 3D printing is raging in the jewelry industry. Expert jewelers are using 3D prototypes to represent hard surface diamonds and jewels. Resin has the quality to imitate both soft and hard surfaces ranging from rubber to ceramics.

Selective Laser Sintering

Selective laser sintering (SLS) is yet again another type of additive manufacturing. It varies from SLA printing with regard to technique and procedure. SLS is a more representative form of printing suitable for industrial use.

Nylon based powders are solidified to formulate an object. Tiny particles are the starting point of the SLS printing process. The first step in this particular printing method is spreading a layer of the powder in the building chamber of an SLS machine. The following steps take place due to the ability of the SLS machine to fuse the particles together.

The SLS machine melts the powder in order to integrate it into a solidified structure. The machine heats the chamber below the melting point of the powder, this aids in tracing the model. The bed of infused particles supports the fused particles. Once a basic structure is established unmerged powder particles are coated on the top layer by layer.

So, now the final product is left to cool down in the printing machine and then removed from the printing station for inspection. The process thoroughly examines the SLS parts for any unseen excess powder or slips.

Both SLA and SLS parts have their own strengths. SLA parts are actively used in medical industries and microfluidics. On the other hand, SLS parts are used to prototype designs for mechanical purposes. The final parts are all set for use in businesses in need.

Deconstructing 3D Printing Machines

Since printing machines do most of the work in SLA 3D Printing and SLS 3D Printing, a formal deconstruction is in order. 3D Printing machines are not as expensive as they were once. Since it is possible to mass-produce the 3D printing machines, thus there has been a significant decrease in their cost.

An archetypal desktop SLA Printing machine is likely to have a UV laser, elevator, liquid photopolymer, XY Scanning mirror, and a sweeper. Therefore, an SLS Printing machine has the attributes corresponding to a basic oven. It consists of a laser power source, scanning mirror, part build chamber, powder bed, leveling roller, and a powder cartridge.

These machines are pawns in the whole process. A proper design is created before the printing takes place and human resource is required to bead blast the final products. Granting we rely on printing machinery, human participation is inclusive.

Taking a Leap in SLA 3D Printing technology

Low force stereolithography is the latest leap towards advancement in 3D Printing. SLA 3D printing has been around for a while, in the meantime, technological was moving towards greater development. These technological progressions have taken a toll on the existing SLA 3D Printing machines.

Low force printing reduces the tension on the surface of parts and sources of high print quality and a flawless exterior. A flexible tank and linear lighting help accomplish LFS 3D printing. The prerequisites for LFS are crucial, without them LFS printing would not bear the same results.

Low Force Stereolithography is still in the works moreover it satisfies the market pull more than the vintage SLA Printing machine. Providing a better finish in any 3D part is the goal every and any manufacturer is aiming towards.

SLA VS SLS- The simple explanation

SLA and SLS 3D printing systems are both efficient methods to assemble 3D products. They are reliant on laser technology. Laser technology is the mutual denominator in both processes. The end-product, machinery, material, size, and cost are the dividers.

Final Product:

SLA and SLS parts have their own distinct features. The difference in SLS and SLA parts is the direct outcome of the way manufacturers produce them. So, SLA parts have extensive details and smoothness.

Its parts have a level surface finish and tight tolerances. since SLA parts offer greater visual accuracy, thus the medial field favors them. SLS parts are not as visually appealing as SLA parts nonetheless they have a sturdier exterior.

Since SLA parts are brittle, thus you do not pair them with mechanics. SLS parts are able to handle hardcore operations. Both parts are valuable in their respective fields.

Material:

The high price factor for SLS Printing derives from its expensive raw material. Although the powders are expensive they are easy to use. The raw material for stereolithography printing is liquid resin. Liquid resin is not only highly dangerous to handle but also has worse post printing results. SLA parts are inspected more than SLS products after printing and that is more often than not a lengthy process.

Raw Materials contribute to the final expenses of the parts and machines. The powders used in SLS machines are expensive and that is why SLS machines are pricier than SLA machines. Resin is fairly common in industries that require it. It is not a rare item.

Size:

SLA printers have a compact size; they are suitable for small scale purposes. Compared to an SLS printer, the size of a SLA printer is miniature. SLS printers are bulky and cover a larger surface area. SLS printers typically create larger models than SLA printers. It is understandable to have a larger build if the result is loftier.

A standard coffee machine has the same size as a standard SLA machine. Manufacturers use nano technology in order to make the technology inside the machines instead of thick wires.

Cost:

Although SLS and SLA 3D printing has become common, the cost of production is fairly high. Therefore, SLA 3D printing is functional on a larger scale and one of the foremost inventions in 3D Printing therefore its price falls below 500USD. SLS Printing machines exercise expensive materials with high transport costs. 5000USD per unit is the retailing price for SLS machines.

Large industries have the capability to bid for any price however small-scale businesses cannot benefit from this technology as of yet. The near future entails mass production for 3D printing machines, hopefully sinking the cost.

Technology:

The technology for SLS and SLA machines are alike. Lasers are mutually present in both machines however the presence of a rotating mirror is obstructive for SLA machines. The rotating mirror in a SLA printing machine reduces precision of the final part. SLS machines face the same problem yet the advanced system shelters for it.

Stronger laser power is the USP for SLS 3D printing machines. The strong laser power inarguably yields better results but then again it is dangerous to handle. Asserting caution with the machine is necessary for any inexperienced personnel.

Final Verdict

The decision power to choose the best 3D Printing machine solely resides with the buyers. To put it simply financial partiality, workspace, and nature of business have an impact on choosing a 3D printer. Therefore, smaller businesses with smaller spending capacity resolve to buy an SLA machine. SLA machines are affordable and give decent results.

Industries looking for unchallenged technology are not reluctant to purchase expensive equipment, they find themselves interested in SLS machines. So, they use high-quality material to manufacturer the parts of SLS, this fact separates them from other parts. SLS machines can forge intricate geometrical shapes that only exist in theory.

Additive manufacturing provides durable prototypes and long-lasting 3D parts at a norm. Thus, this technology has surpassed others in the matter of versatility and throughput. The supremacy of 3D Printing in fashioning exceptional structures remains unmatched.

Being the leaders in the Printing Industry, we can assure you that we provide top-notch quality manufacturing services. We ensure the highest industry standards as we firmly believe in having a long-term, healthy relationship with our consumers.

For further assistance regarding SLA 3D Printing and SLS 3D Printing, have a look at our website now. You can contact our customer service and they will guide you in the best possible way.