Inox Lost Wax Casting: Learn About Lost Wax Casting

2020-08-26Everything You Need To Know About Inox Lost Wax Casting

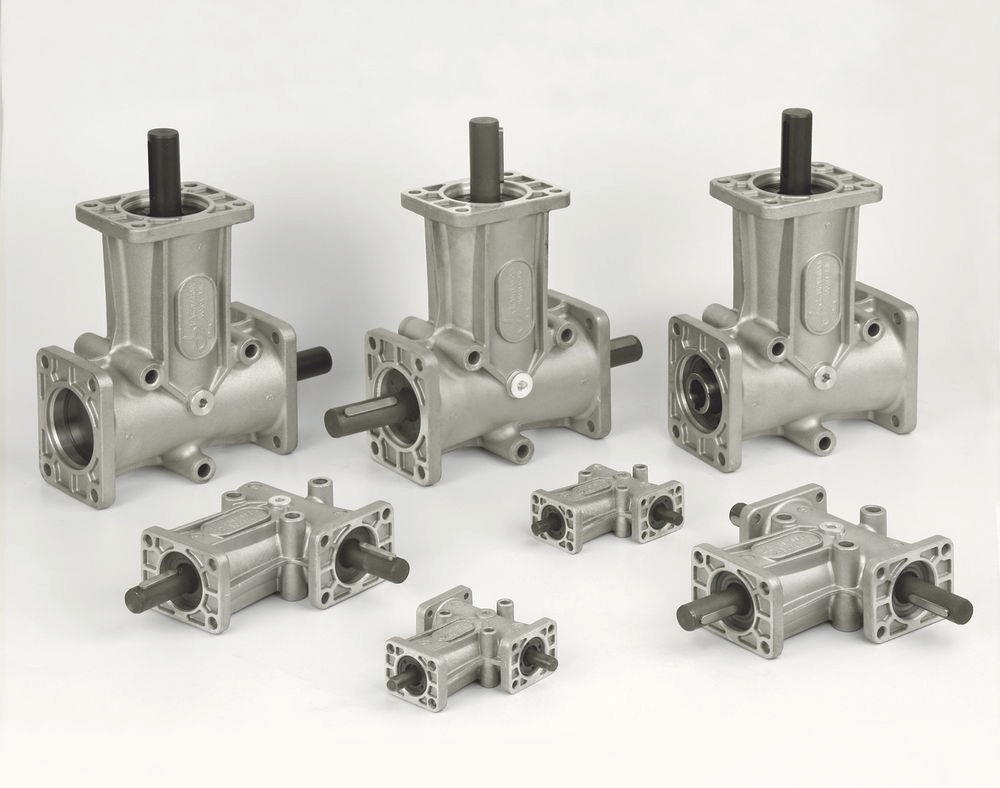

Lost wax casting also popular as the precision casting or the investment casting is extremely effective for manufacturing complex shapes and different dimensions. You can use this technique for numerous parts and components. For instance, manufacturers greatly rely on inox lost was casting to yield better products.

You will be surprised to know that the popular metal casting process has been around for a very long time. Although, the modern lost wax casting is sophisticated and effective, however, people have been using the basic concept for ages.

Due to its numerous benefits, including integrity, repeatability, and replicating detail ability, it is the first preference for most casting manufacturers. In this blog post, we will tell you everything that you need to know about the lost wax casting process.

Lost Wax Casting: The History, and the Present

History

As we did mention above that the basic concept of lost wax casting has been around for thousands of years now. The earliest example of this particular process can be dated back to 3700 BC. Of course, they discovered this after tests with carbon 14 dating.

These initial products are discovered in southern Israel, in the cave of Treasure hoard. You can find earlier examples of this concept in many different regions and countries.

Previously, the Lost wax technique was the main method for creating both small as well as large scale casting. A 6, 000-year-old copper-amulet was found in South Asia, Pakistan. Back then, people used the lost wax casting technique to create the copper amulet.

Also, other places including Europe, Africa, Greece East Asia, Egypt, and others have found objects are were crafted using this method.

With lost wax casting, it is possible to manufacturer intricate metal components. These components are then used in a number of situations and industries. The technique can be old, but it still holds great importance in the casting industry today.

Working of the Lost Wax Casting Process

The modern lost waxing casting process is a standardized process. This means that even though every manufacturer would have its own technique to cast a certain metal. However, the basic technique would remain the same.

The process involves a number of stages ranging from wax model creation to the final finished metal piece.

See the steps below for more information.

- The first step is to cut the aluminum tool. For this purpose, manufacturers today use 3D-CAD information.

- Use the tools to make an original positive model. It would be a component in the wax.

- Then the manufacturer needs to assemble the wax onto a runner system. They generally call it the assembly-tree.

- Next comes the building of a ceramic shell. The manufacturer would use a dipping and drying process for the creation of this ceramic shell.

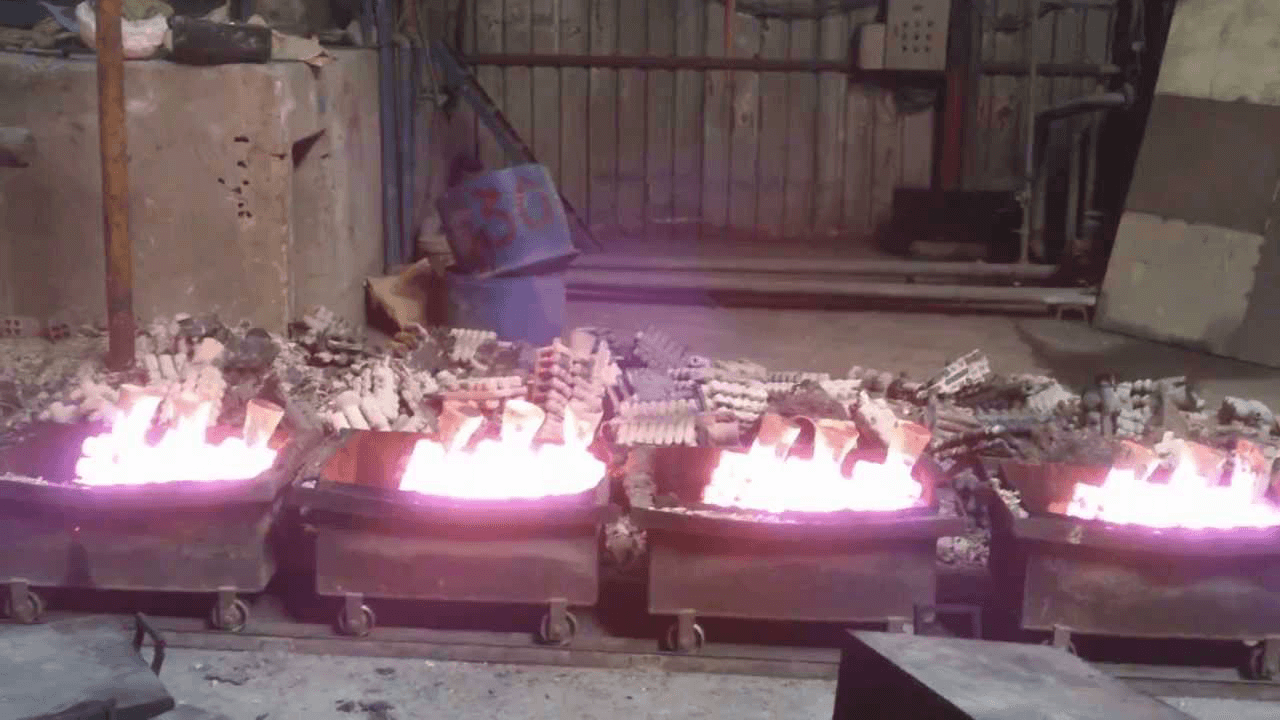

- In order to provide mechanical strength, the shell first needs to be dewaxed using the high-pressure steam. And then the manufacturer fires it in the oven.

- After pre-heating the shell, it is time to pour the molten metal into it.

- Wait for the metal to cool, and then break the ceramic off.

- Next coming the cutting of the parts from the tree.

- Ingate is ground-off

- If there is a need, the manufacturer would set, finish, and machine it.

- Lastly, the inspection takes place. This is to ensure that the profile meets all the requirements.

When and Where to Use the Process

Manufacturers need to understand as to where and when to use the inox lost wax casting process. After all, different industries have different applications of the casting process. For example, initially and for a long-time, the jewellers along with sculptures makers and small parts makers have been using this technique.

However, technological advancement and sophisticated equipment makes the technique the most common casting method. It now holds great importance in a number of industries including the rail, automotive, mining, and the medical industry.

Even the aerospace industry greatly relies on this technique for high-quality, precise, and robust parts. It seems that almost every manufacturing methods that require complex, yet precise metal parts or components would use the low wax casting process.

Types of Metals

ስለ inox የጠፋውን ሰም የመጣል ሂደት ሌላው ታላቅ ነገር ሁለገብነቱ ነው ፡፡ አሠራሩ አምራቾች ከፍተኛ ጥራት ያላቸውን ጠንካራ ክፍሎችን ለመፍጠር ሰፋፊ ምርቶችን እንዲጠቀሙ ያስችላቸዋል ማለት ነው ፡፡

ከዚህ በታች ብዙ አምራቾች የሚጠቀሙባቸው የተለመዱ ቁሳቁሶች ጥቂቶቹ ናቸው ፡፡

- የአሉሚኒየም አሎይስ

- በመዳብ ላይ የተመሰረቱ ቅይሎች

- ኮባልትና ኒኬል አላይስ

- የካርቦን ብረቶች

- ሙቀት መቋቋም የሚችሉ ቅይሎች

- አይዝጌ-ብረት አሎይስ

የጠፋ-ሰም የመውሰጃ ዘዴ ጥቅሞች

ሂደቱ እጅግ በጣም ብዙ ዲዛይን ተለዋዋጭ እና እጅግ በጣም ትክክለኛነትን ይሰጣል ፡፡ ስለዚህ ፣ ውስብስብ ለሆኑ አነስተኛ መጠን ያላቸው ክፍሎች በጣም ጥሩ ምርጫ ነው።

ይህንን ዘዴ በመጠቀም በሚፈጥሯቸው ተዋንያን ውስጥ ሎጎዎችን ፣ የምርት መታወቂያዎችን ፣ ቁጥሮችን ከሌሎች ጋር ማከል ይችላሉ ፡፡

ኢንቬስትሜንት መውሰድ ተጨማሪ ሰልፍ አያስፈልገውም ፡፡ ለምሳሌ ፣ ላዩን ማበጠር ወይም ማጠናቀቅ ፡፡ ከሌሎቹ ሁሉ የመጣል ቴክኒኮች ጋር በማነፃፀር የተሻለ ውጤት ያስገኛል ፡፡

ኢኖክስ የጠፋ ሰም መጣል ጠንካራ የሆኑ ምርቶችን ያስከትላል እንዲሁም እንደ አሸዋ የመጣል ሂደት ካሉ ሌሎች የመውሰድ ሂደቶች የበለጠ ጠንካራ መቻቻል አላቸው ፡

ተጨማሪ የመጨረሻ ማጠናቀቂያ እጥረት አጠቃላይ ወጪን ይቀንሰዋል። ስለሆነም ዘዴውን ወጪ ቆጣቢ ማድረግ ፡፡

የመጣል ዘዴ ትክክለኛውን ቅርፅ ይሰጣል ፣ ስለሆነም የቁሳቁሱን ወጪ ይቀንሰዋል።

በተጨማሪም ውድ የማሽነሪ ሥራዎችን ይቀንሰዋል ፣ ስለሆነም የመነሻ መሣሪያ ወጪን ያስከትላል።

One of the greatest advantages of the የጠፋው ሰም የመጣል ለአካባቢ ተስማሚ ነው ፡ እሱ የሚፈጥርባቸውን የሰም ምርቶች መልሶ ማግኘት እና እንደገና ጥቅም ላይ ማዋል ስለሚቻል ፡፡

ዘዴው የክፍሎቹን አፈፃፀም ከፍ ለማድረግ ይረዳል ፡፡

ማጠቃለያ

ምንም እንኳን inox ያጣው ሰም የመጣል ሂደት በወረቀት ላይ ቀላል ቢመስልም ግን ሰፊ እና ከፍተኛ የቴክኒክ ሂደት ነው ፡፡ ስኬታማነቱን ለማረጋገጥ አምራቹ አምራች እውቀት እና ሰፊ ክህሎቶች ሊኖሩት ይገባል ፡፡

በ Essaii እኛ ቦርድ ላይ ምርጥ ሰዎች እንደ እኛ ዝቅተኛ ሰም እንደሚጣል ከፍተኛ ጥራት ይሰጣሉ. ለሁሉም የመጣል መስፈርቶችዎ የአንድ-ማቆሚያ መፍትሔዎ እንሆናለን ፡፡

ለበለጠ መረጃ ዛሬ ያነጋግሩን.