Inox Lost Wax Casting: Erfahren Sie mehr über Lost Wax Casting

2020-08-26Alles, was Sie über Inox Lost Wax Casting wissen müssen

Wachsausschmelzguss, auch als Präzisionsguss oder Feinguss beliebt, ist äußerst effektiv für die Herstellung komplexer Formen und unterschiedlicher Abmessungen. Sie können diese Technik für zahlreiche Teile und Komponenten verwenden. Zum Beispiel verlassen sich Hersteller stark auf Inox-Gussverluste, um bessere Produkte zu erhalten.

You will be surprised to know that the popular metal casting process has been around for a very long time. Although, the modern lost wax casting is sophisticated and effective, however, people have been using the basic concept for ages.

Due to its numerous benefits, including integrity, repeatability, and replicating detail ability, it is the first preference for most casting manufacturers. In this blog post, we will tell you everything that you need to know about the lost wax casting process.

Lost Wax Casting: The History, and the Present

History

As we did mention above that the basic concept of lost wax casting has been around for thousands of years now. The earliest example of this particular process can be dated back to 3700 BC. Of course, they discovered this after tests with carbon 14 dating.

These initial products are discovered in southern Israel, in the cave of Treasure hoard. You can find earlier examples of this concept in many different regions and countries.

Previously, the Lost wax technique was the main method for creating both small as well as large scale casting. A 6, 000-year-old copper-amulet was found in South Asia, Pakistan. Back then, people used the lost wax casting technique to create the copper amulet.

Also, other places including Europe, Africa, Greece East Asia, Egypt, and others have found objects are were crafted using this method.

With lost wax casting, it is possible to manufacturer intricate metal components. These components are then used in a number of situations and industries. The technique can be old, but it still holds great importance in the casting industry today.

Working of the Lost Wax Casting Process

The modern lost waxing casting process is a standardized process. This means that even though every manufacturer would have its own technique to cast a certain metal. However, the basic technique would remain the same.

The process involves a number of stages ranging from wax model creation to the final finished metal piece.

See the steps below for more information.

- The first step is to cut the aluminum tool. For this purpose, manufacturers today use 3D-CAD information.

- Use the tools to make an original positive model. It would be a component in the wax.

- Then the manufacturer needs to assemble the wax onto a runner system. They generally call it the assembly-tree.

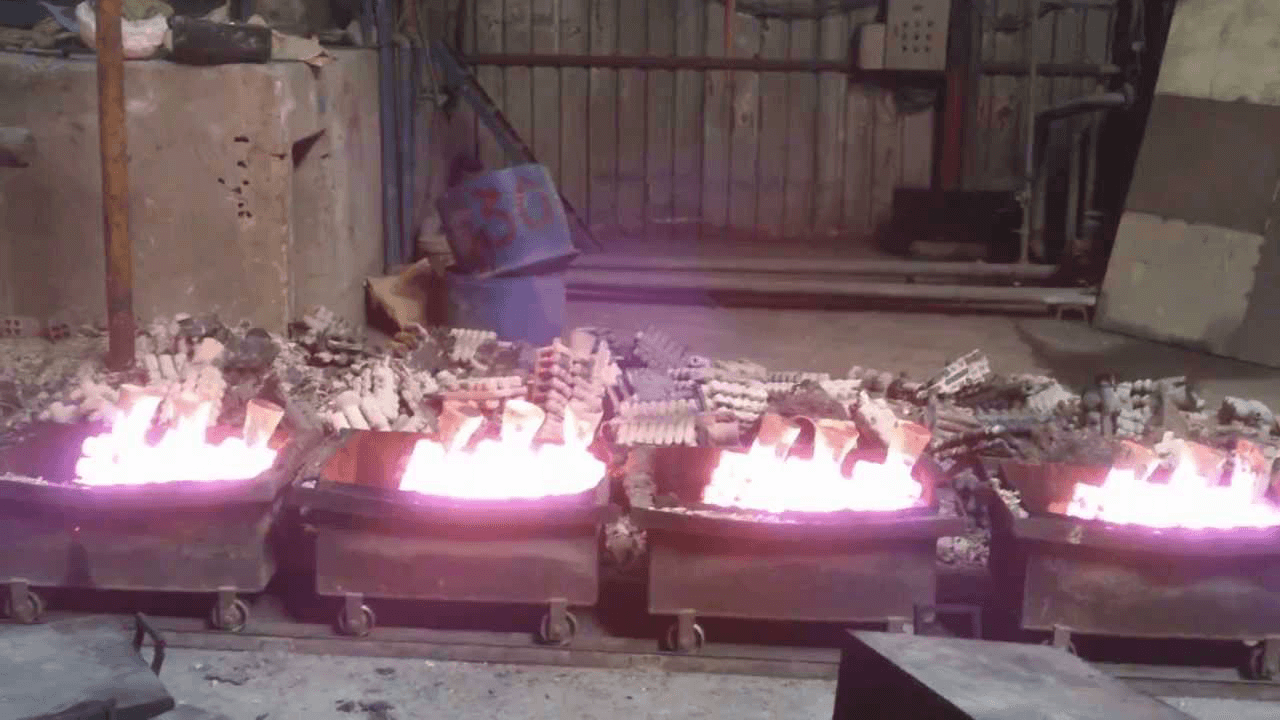

- Next comes the building of a ceramic shell. The manufacturer would use a dipping and drying process for the creation of this ceramic shell.

- In order to provide mechanical strength, the shell first needs to be dewaxed using the high-pressure steam. And then the manufacturer fires it in the oven.

- After pre-heating the shell, it is time to pour the molten metal into it.

- Wait for the metal to cool, and then break the ceramic off.

- Next coming the cutting of the parts from the tree.

- Ingate is ground-off

- If there is a need, the manufacturer would set, finish, and machine it.

- Lastly, the inspection takes place. This is to ensure that the profile meets all the requirements.

When and Where to Use the Process

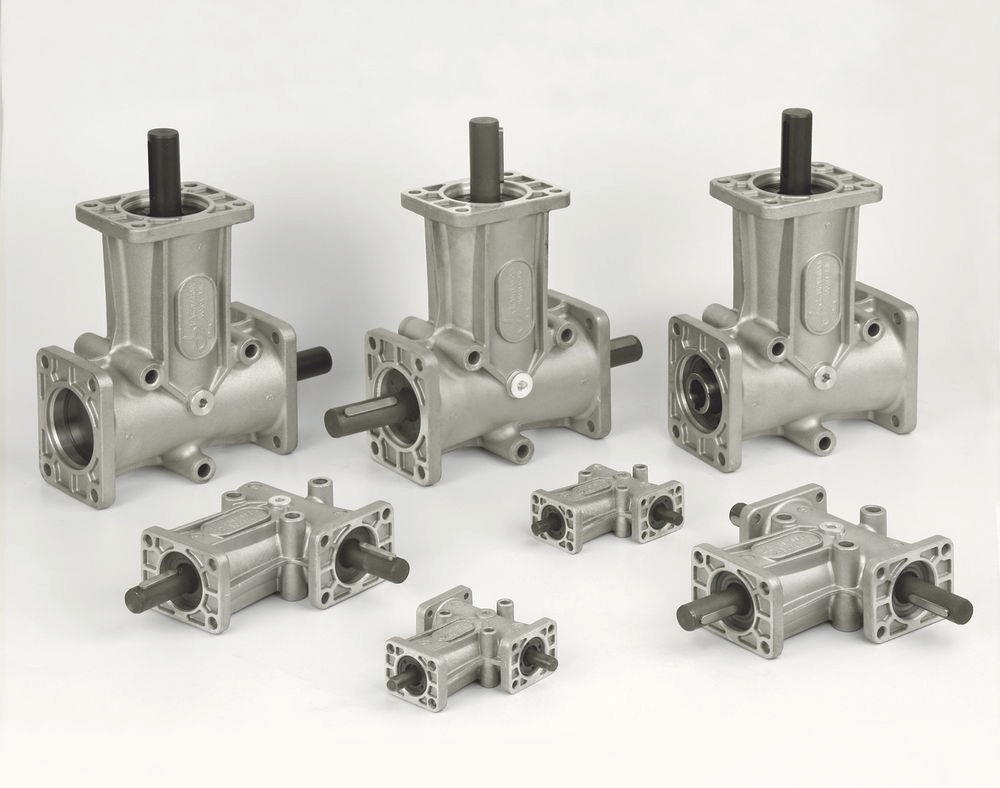

Manufacturers need to understand as to where and when to use the inox lost wax casting process. After all, different industries have different applications of the casting process. For example, initially and for a long-time, the jewellers along with sculptures makers and small parts makers have been using this technique.

However, technological advancement and sophisticated equipment makes the technique the most common casting method. It now holds great importance in a number of industries including the rail, automotive, mining, and the medical industry.

Even the aerospace industry greatly relies on this technique for high-quality, precise, and robust parts. It seems that almost every manufacturing methods that require complex, yet precise metal parts or components would use the low wax casting process.

Types of Metals

Eine weitere großartige Sache beim Inox-Wachsausschmelzverfahren ist seine Vielseitigkeit. Dies bedeutet, dass die Hersteller mit diesem Verfahren eine breite Palette von Produkten verwenden können, um hochwertige, robuste Teile herzustellen.

Im Folgenden sind einige der gängigen Materialien aufgeführt, die die meisten Hersteller verwenden.

- Aluminiumlegierungen

- Legierungen auf Kupferbasis

- Kobalt- und Nickellegierungen

- Kohlenstoffstähle

- Hitzebeständige Legierungen

- Edelstahllegierungen

Vorteile der Wachsausschmelzmethode

Das Verfahren bietet ein immenses Design, Flexibilität und ein hohes Maß an Präzision. Daher ist es eine ausgezeichnete Wahl für komplexe, kleine Teile.

Sie können der Besetzung, die Sie mit dieser Methode erstellen, unter anderem Logos, Produkt-IDs und Nummern hinzufügen.

Feinguss benötigt keine zusätzliche Prozession. Zum Beispiel Oberflächenpolieren oder Veredeln. Es liefert bessere Ergebnisse im Vergleich zu allen anderen Gusstechniken.

Inox lost wax casting results in products that are robust and they have a tighter tolerance than other casting processes such as the sand-casting process.

The lack of additional final finishing reduces the overall cost. Thus, making the technique cost-efficient.

The casting technique provides the exact shape, thus reducing the material cost.

It also decreases the expensive machining operations, thus resulting in a decrease of the initial tooling cost.

One of the greatest advantages of the inox lost wax casting technique is that it is environment friendly. As it is possible to reclaim and reuse the wax products that it creates.

The technique also helps enhance the performance of the parts.

Zusammenfassung

Obwohl das Inox-Wachsausschmelzverfahren auf Papier einfach erscheint, ist es ein umfangreiches und hochtechnisches Verfahren. Um seinen Erfolg sicherzustellen, muss der Hersteller über Gusskenntnisse und umfassende Fähigkeiten verfügen.

Bei Essaii höchster Qualität, da wir die besten Mitarbeiter an Bord haben. Wir sind Ihre Komplettlösung für alle Ihre Gussanforderungen.

For more information, Kontaktieren Sie uns noch heute, um.